Level adjustment systems and adjustable pin chuck thereof

A technology for adjusting system and flatness, which is applied in the field of flatness adjustment system for flatness, which can solve the problem of photoresist leaving and achieve the effect of good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

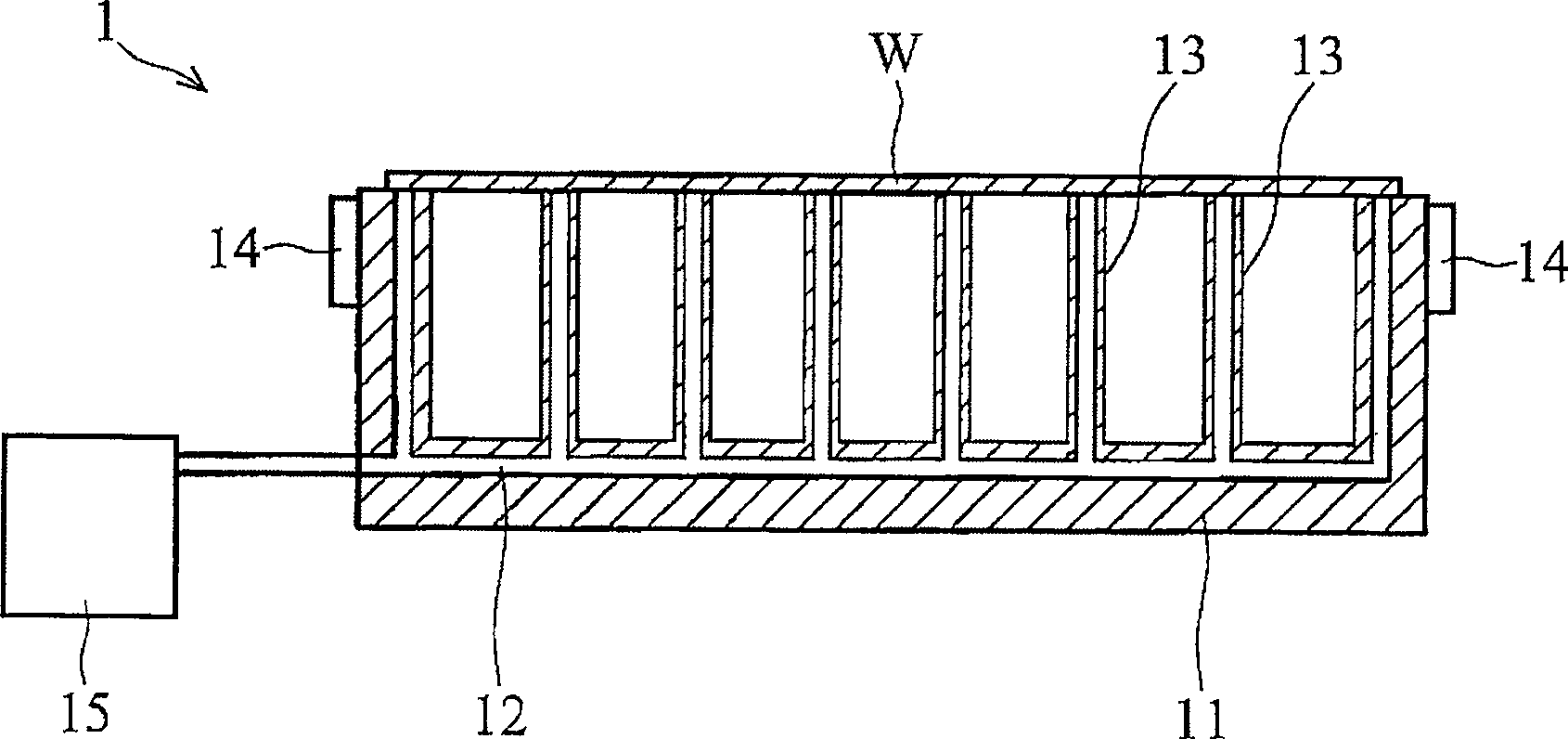

[0086] see Figure 4 , the flatness adjustment system 100 of this embodiment mainly includes an adjustable needle-type bearing suction cup 110 , an air suction device 120 , a flatness detection device 130 and a length control device 140 .

[0087] Another example Figure 4 As shown, the adjustable needle-type bearing suction cup 110 has a base 111 and a plurality of adjustable thimbles 112 . At the same time, the base 111 also has a concave portion 113 and an air extraction pipeline 114 , the air extraction pipeline 114 is connected to the concave portion 113 , and a plurality of adjustable thimbles 112 are evenly arranged in the concave portion 113 . In this embodiment, each adjustable thimble 112 also has a piezoelectric element 115 and a bearing element 116 , the piezoelectric element 115 is disposed on the base 111 , and the bearing element 116 is disposed on the piezoelectric element 115 . In addition, each bearing element 116 also has an L-shaped through hole 117 , and...

no. 2 example

[0095] In this embodiment, the same elements as those in the first embodiment are marked with the same symbols.

[0096] see Figure 5 , the flatness adjustment system 200 of this embodiment mainly includes an adjustable needle-type bearing suction cup 110 , an air suction device 120 , a flatness detection device 230 and a length control device 140 .

[0097] still as Figure 5 As shown, the flatness detection device 230 is disposed on the adjustable needle-type loading suction cup 110 . More specifically, the flatness detection device 230 of this embodiment is an air pressure rangefinder, and has a plurality of air blowing lines 231 and a plurality of pressure sensors 232 . Each pressure sensor 232 is disposed on each blowing pipeline 231 and is electrically connected to the length control device 140 .

[0098] As for other components or features of this embodiment are the same as those of the first embodiment, in order to make the description of the present invention clea...

no. 3 example

[0102] In this embodiment, the same elements as those in the first embodiment are marked with the same symbols.

[0103] see Image 6 , the flatness adjustment system 300 of this embodiment mainly includes an adjustable needle-type bearing suction cup 110 , an air suction device 120 , a flatness detection device 330 and a length control device 140 .

[0104] still as Image 6 As shown, the flatness detection device 330 is disposed on the adjustable needle-type loading suction cup 110 . More specifically, the flatness detection device 330 of this embodiment is a capacitive distance meter, and the capacitive distance meter has a plurality of parallel metal sheets 331 , and the plurality of metal sheets 331 are electrically connected to the length control device 140 .

[0105] As for other components or features of this embodiment are the same as those of the first embodiment, in order to make the description of the present invention clearer and easier to understand, repeated d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com