High differential pressure high accuracy cage type pressure regulating device

A high-precision, high-pressure differential technology, used in fluid pressure control, safety valves, engine components, etc. Adjustment accuracy is limited and other problems, to achieve the effect of small fluctuation, prolong service life and avoid turbulent phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

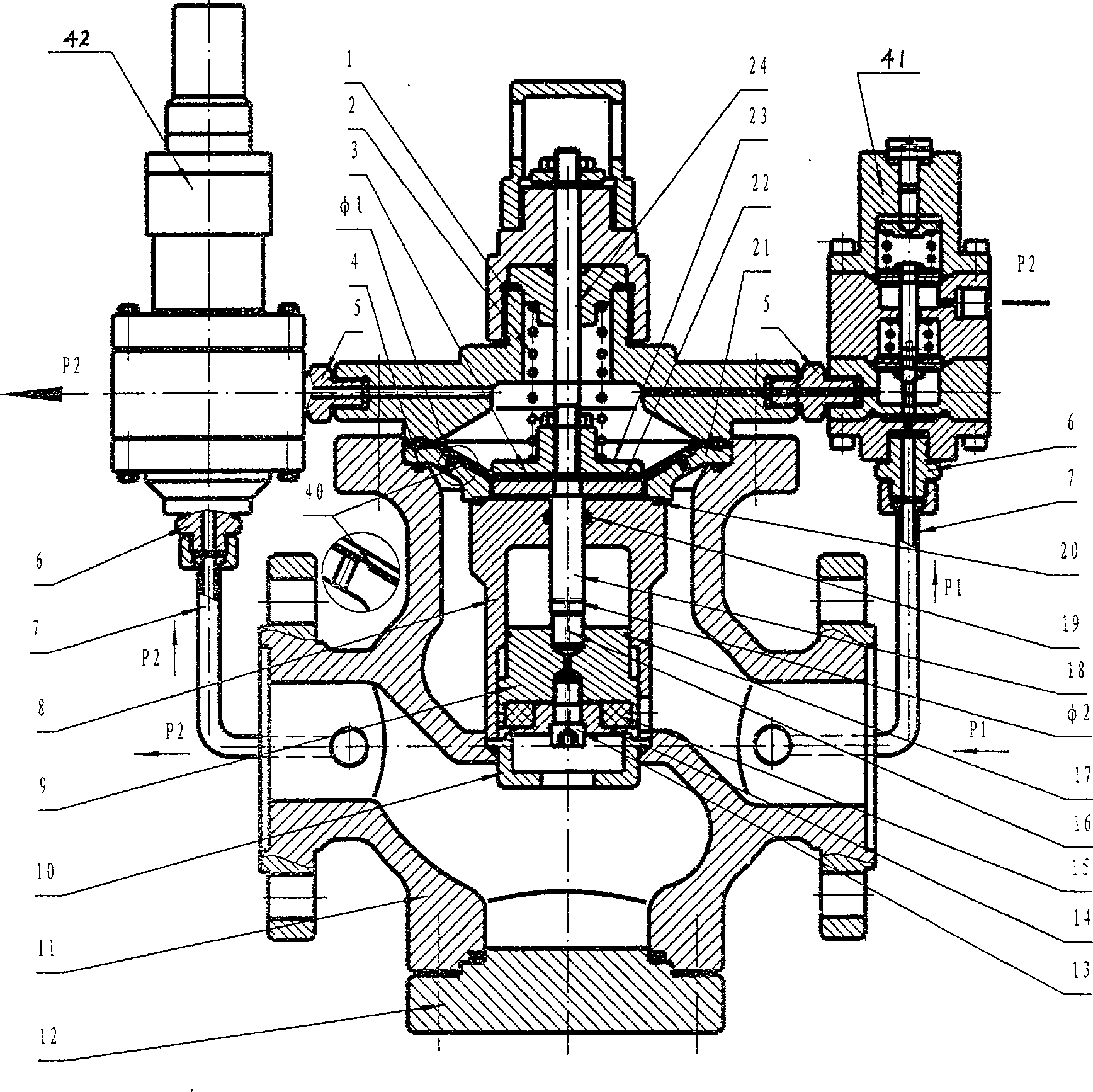

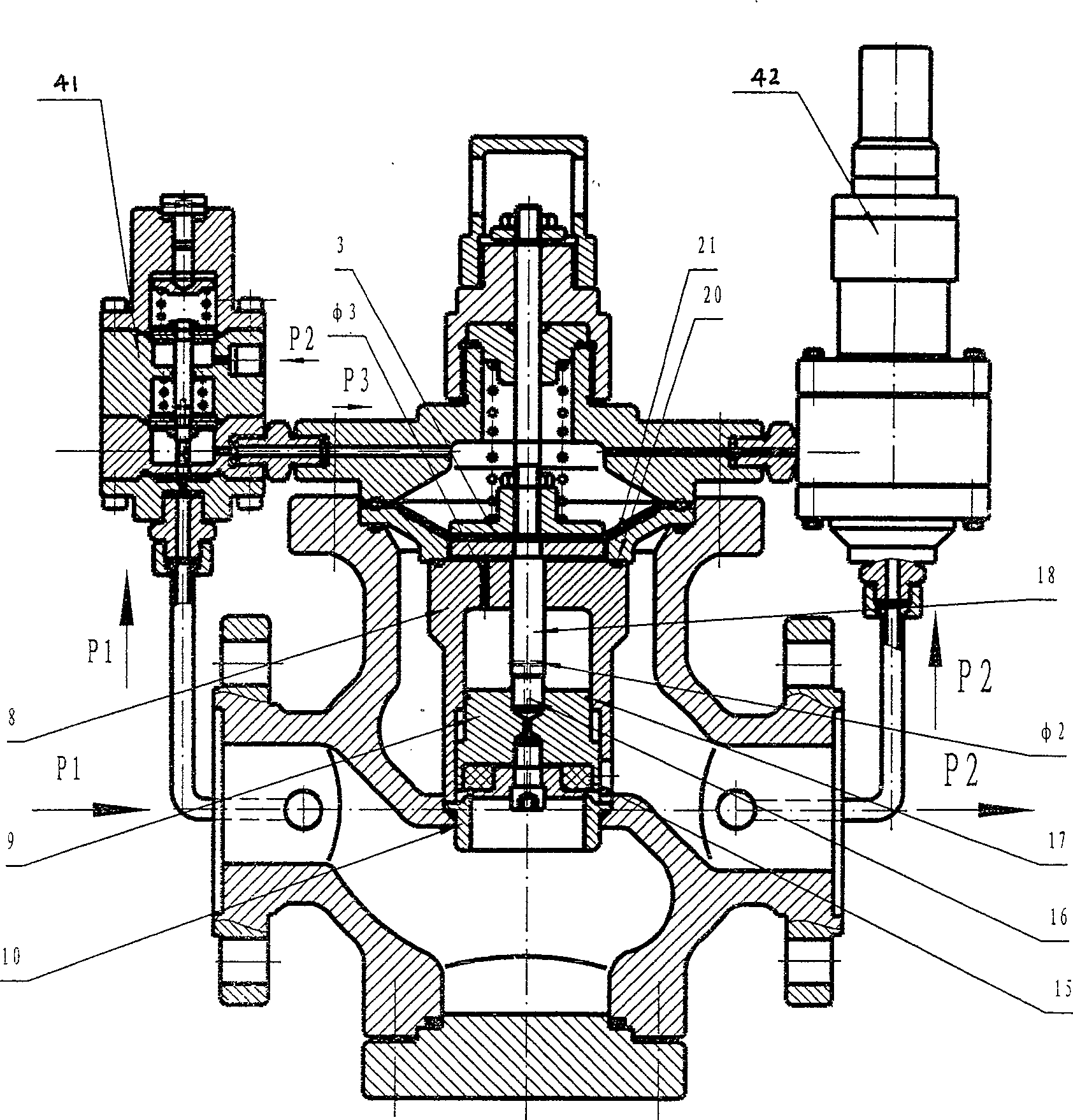

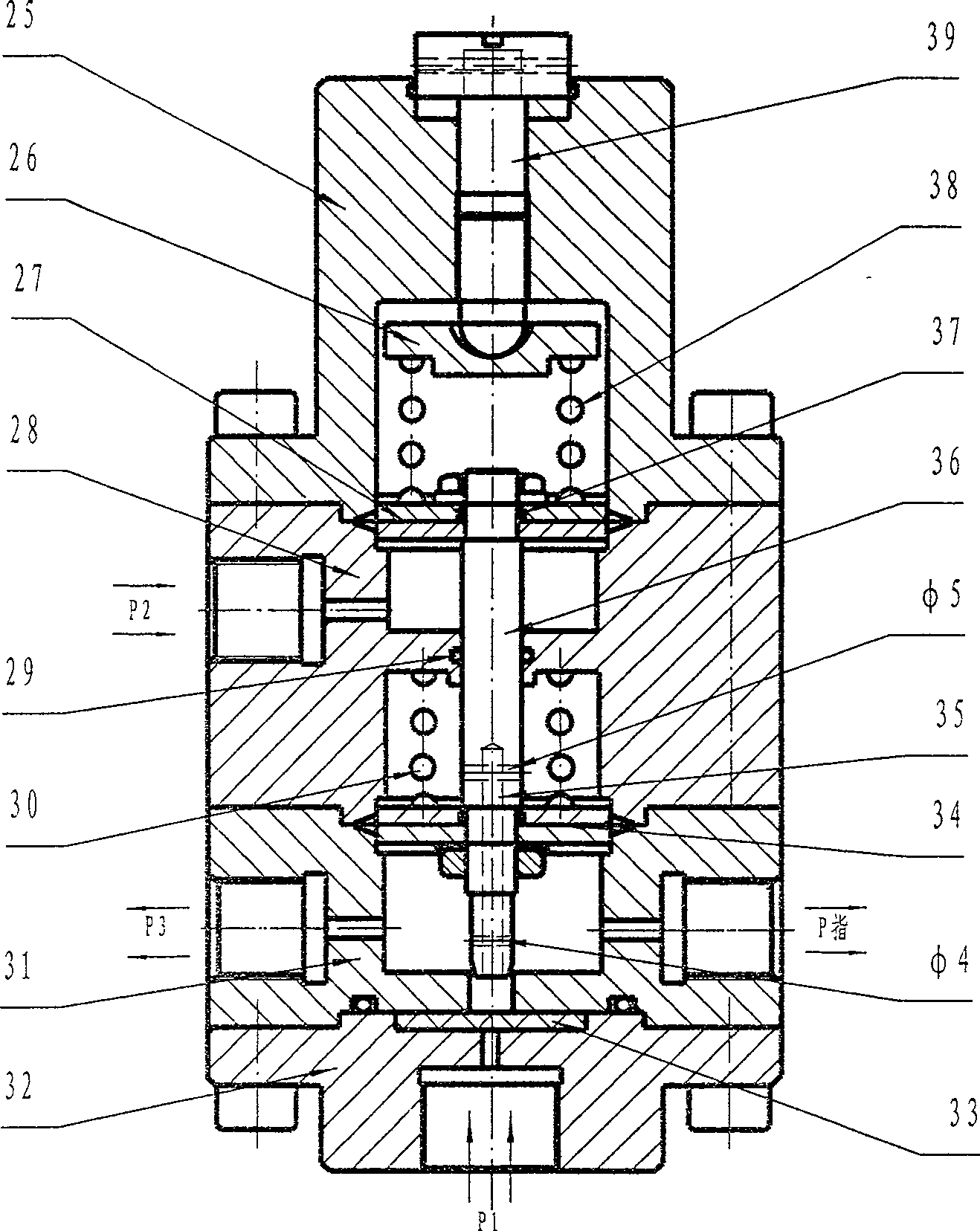

[0022] The present invention will be further described below according to the accompanying drawings:

[0023] figure 1 Shown is one of the embodiments of the present invention. The pressure regulator of the present invention is composed of a main valve, a pressure stabilizing valve 41 and a command valve 42 arranged on the main valve. A membrane is arranged above the valve sleeve 8 of the main valve. Pad 21, with the rubber diaphragm 3 as the transmission mechanism, the valve stem 18, the valve core 9, and the valve seat 10 as the actuator, the valve core 9 is a cylindrical stepped plunger-shaped valve core, and its upper and lower end surfaces are connected by a balance hole 16, The bottom end surface is embedded with a non-metallic annular gasket 15, which forms a sealing pair with the conical boss end surface of the valve seat 10. The pressure stabilizing valve 41 is mainly composed of the valve box between the upper and lower covers and the device inside the valve box. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com