Tank shaped container with lid

A container and can-like technology, applied in the directions of lids, caps, removable lids/covers, etc., can solve the problems of sudden, obstructing the unlocking and opening movement of the lid, impact type, etc., and achieve the effect of sensitive unlocking and opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

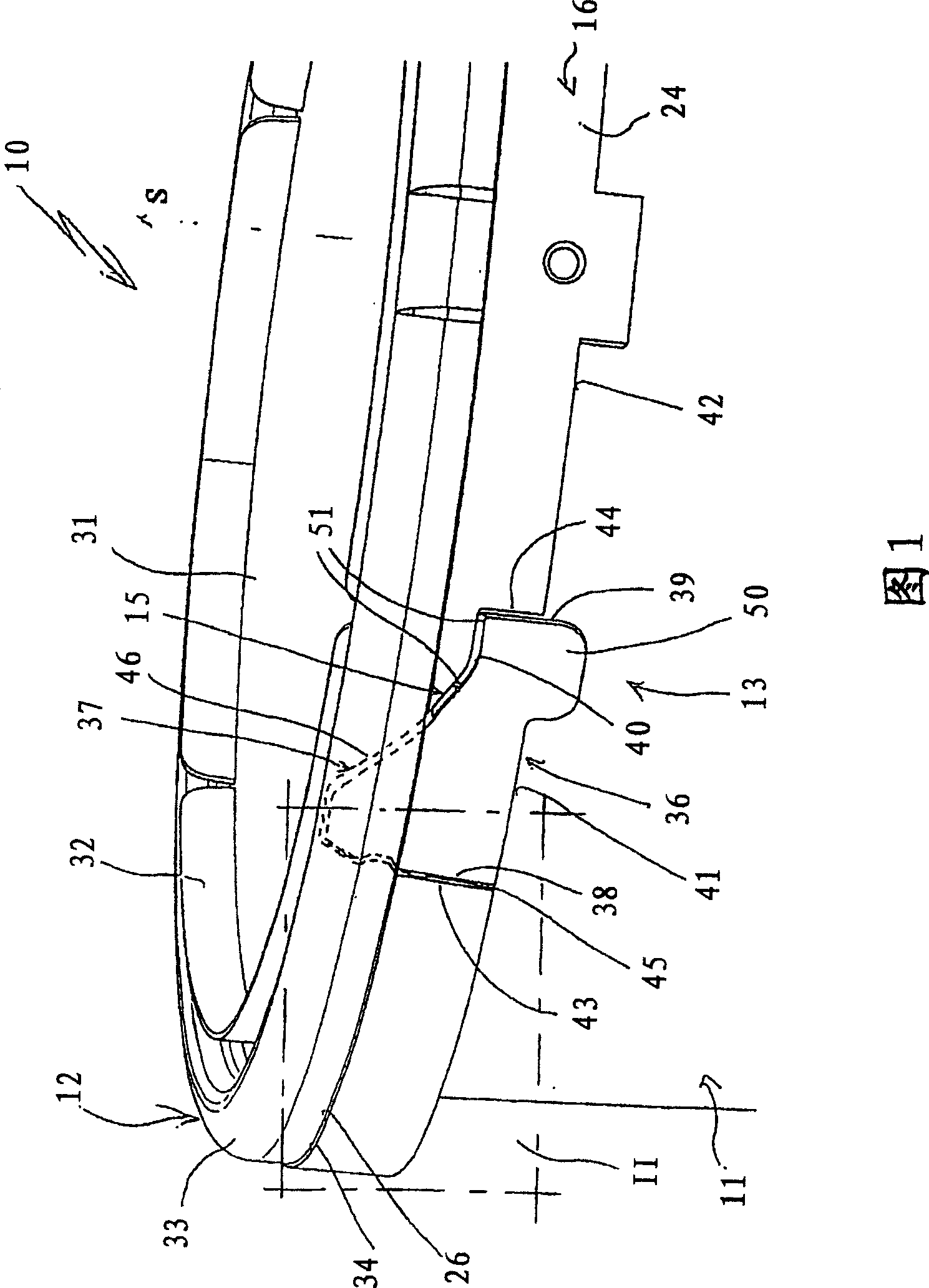

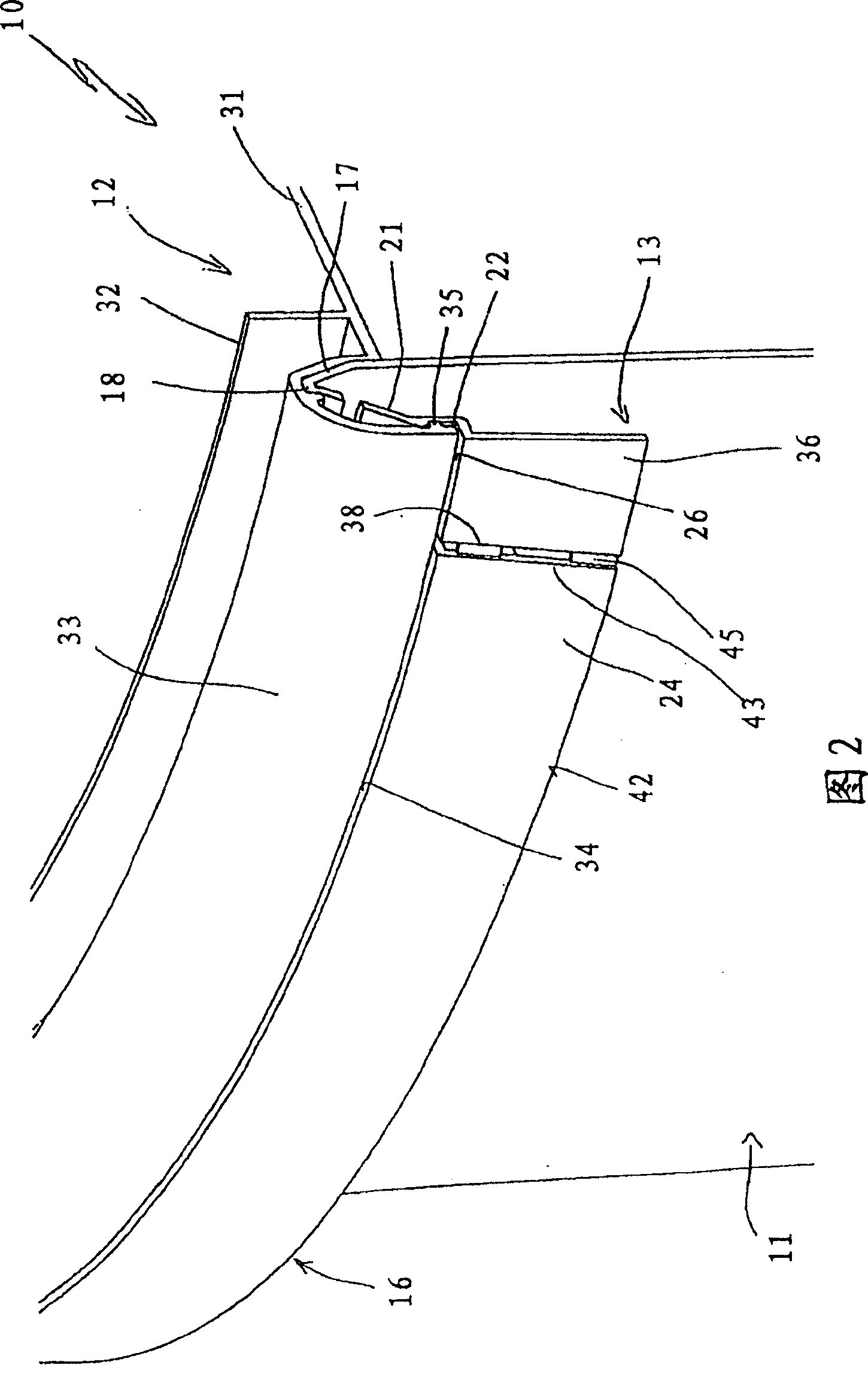

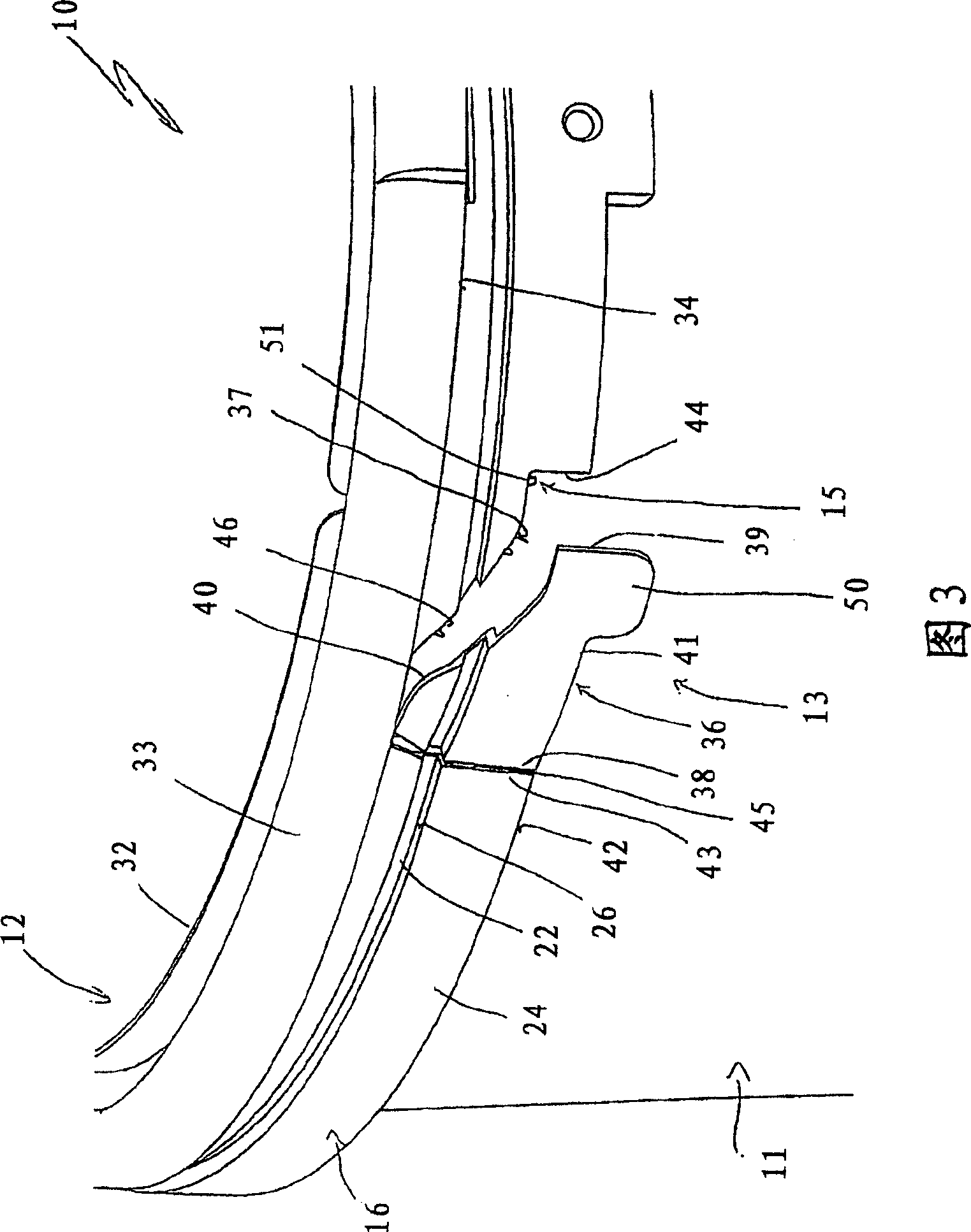

[0027] The container according to the first embodiment shown in FIGS. 1 to 7 is a tub 10 , 10 ′, 10 ′ formed from plastic, the tub body 11 being covered by a cover 12 also formed from plastic. As will also be explained, the lid 12 is locked on the barrel body 11 in such a way that the lid 12 can only be opened by an opening aid 13, 13' or 13" combined on the barrel body 10. .

[0028] The barrel body 11 of the barrel 10, 10', 10" faces away from the bottom and constitutes the upper end of the bung boundary, and is made into one piece with an annular flange 16 whose section is generally roof-shaped, and the annular flange 16 surrounds the barrel body at a distance 11. The annular flange 16 has a narrow first roof-like part 17 formed on the barrel body 11, and connects a wider second roof part 19 on the roof ridge 18 constituting the support of the cover 12. The second roof part 19 has a planar portion 21 adjacent to the ridge 18, which is separated from the lower free flange p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com