Composition type draw gear of locomotive

A traction device and combined technology, applied in the directions of traction device, transportation and packaging, railway car body parts, etc., can solve the problems of complex structure of intermediate bogie traction device, increased maintenance workload, low adhesion utilization rate, etc. Locomotive maintenance workload and operating costs, reducing maintenance workload and operating costs, and the effect of improving the carrying capacity of the locomotive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

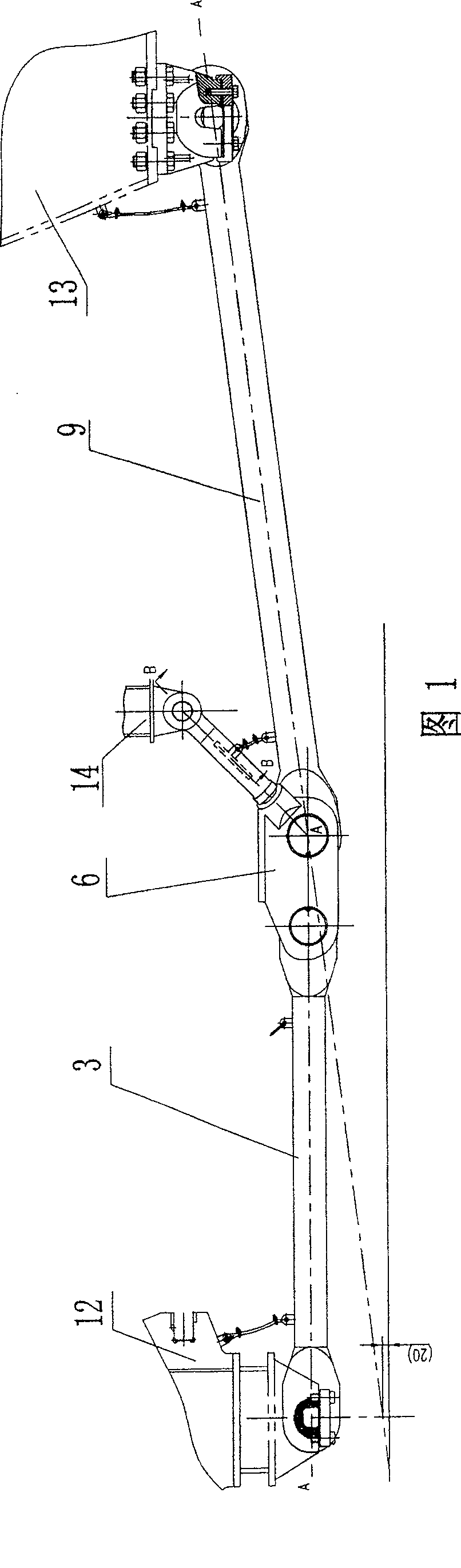

[0013] The accompanying drawings show an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

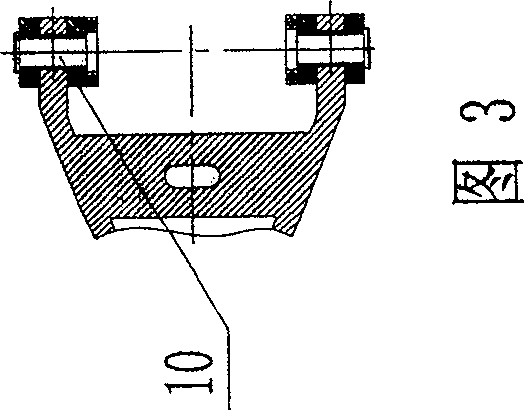

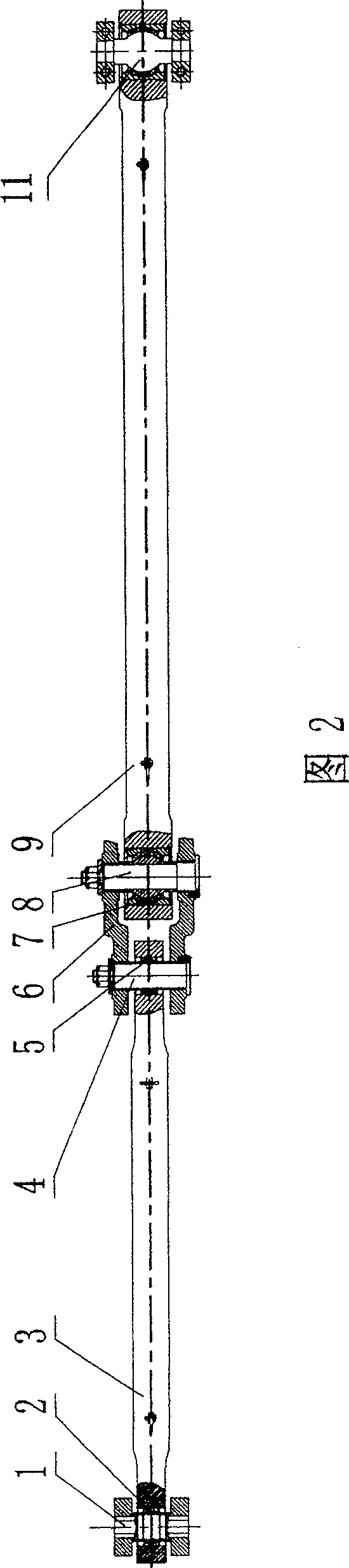

[0014] It can be seen from the accompanying drawings that the present invention is a combined traction device. The traction device of the bogies at both ends and the traction device of the middle bogie adopt different structural forms respectively, wherein the bogies at both ends adopt the central low position Push-pull diagonal tie rods, while the middle bogie adopts a central push-pull flat tie rod; the central low-position push-pull diagonal tie rod structure of the bogies at both ends includes a flat draw bar 3, a triangular brace 6 and an oblique draw bar 9. One end of the flat draw bar 3 links to each other with the frame draw beam 12 by the first draw pin 1, and the other end links to each other with a corner of the triangular brace by the second draw pin 4, and a joint bearing 2 and 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com