Rotary-piston engine

A piston engine, rotary motion technology, applied in the direction of rotary piston engine, oscillating piston engine, rotary or oscillating piston engine, etc., can solve the problem that the cylinder head is no longer available to accept ignition rods or spark plugs, and there is no engine, etc. , to achieve the effect of simple adjustment and variable displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

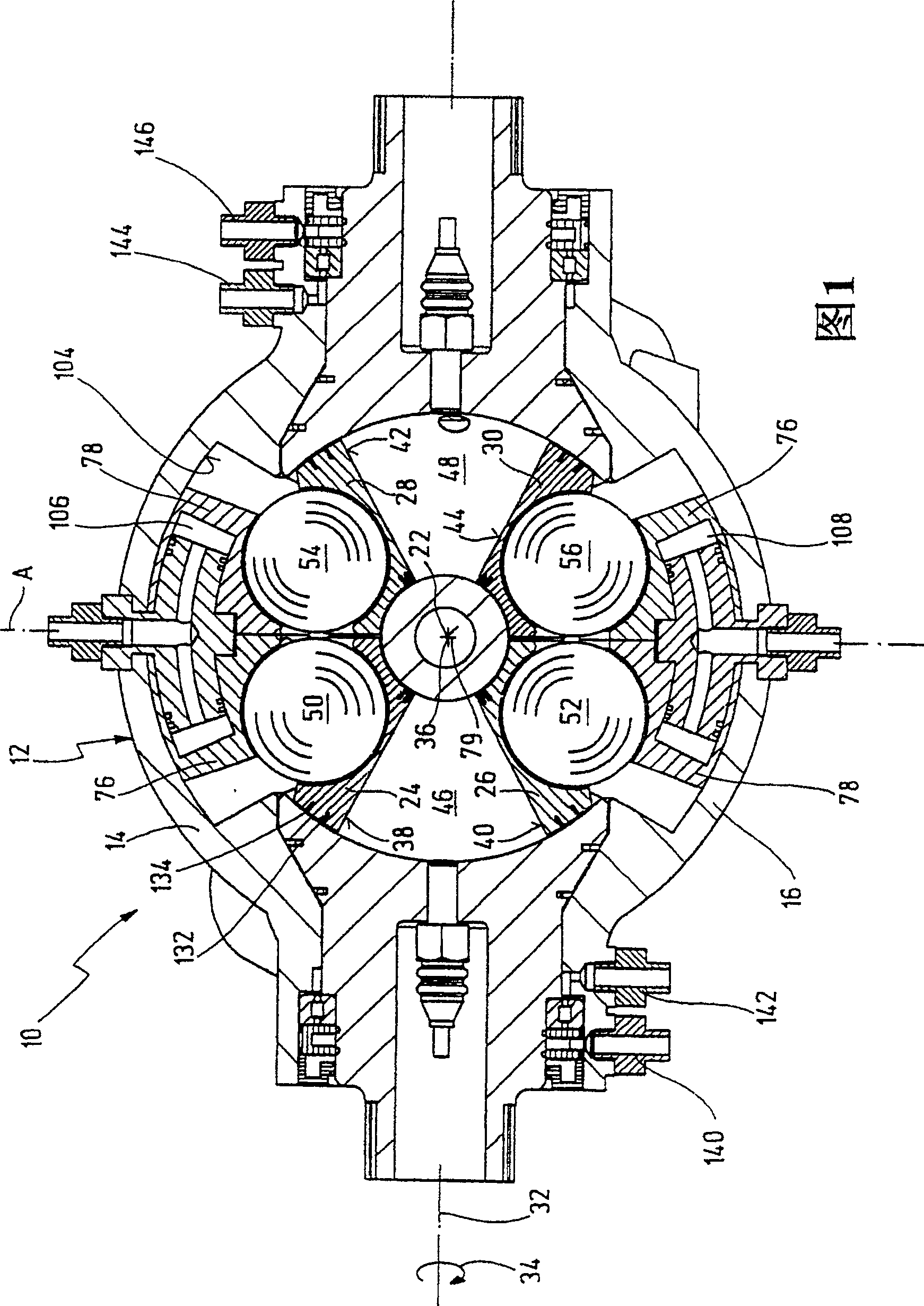

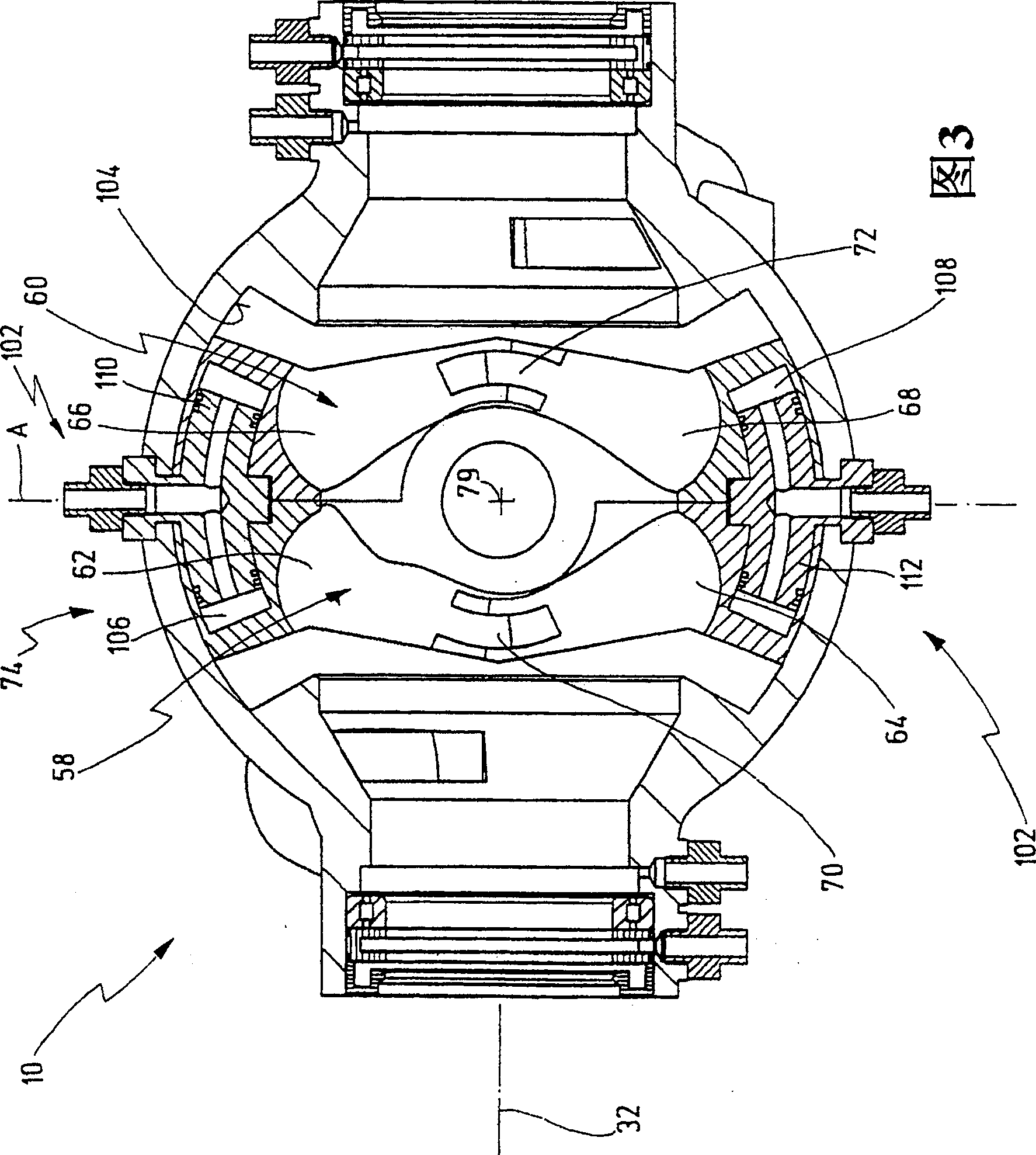

[0060] Figures 1-3 and Figures 6-8 show a rotary piston engine with common reference numeral 10 in different views. 4 and 5 show further details of the rotary piston engine 10 .

[0061] The rotary piston engine 10 is designed as an internal combustion engine in the present exemplary embodiment.

[0062] The rotary piston engine 10 has a housing 12 consisting of two housing parts 14 and 16 . The housing parts 14 and 16 each have a flange, of which only the flange 18 of the housing part 14 is shown in the figures. In the flange there are a large number of holes 20a-20h for passing bolts in order to bolt the two housing parts 14 and 16 to each other via the flange.

[0063] The interior of the shell is spherical or spherically symmetrical, wherein the center point of the ball is marked with reference numeral 22 in FIG. 1 .

[0064] Inside the housing 12 are arranged four pistons 24 , 26 , 28 and 30 . Pistons 24 - 30 are rotatable in housing 12 together around a housing-fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com