Method for fabricating precast products and forming appliance

A molding device and manufacturing method technology, applied in the direction of manufacturing tools, ceramic molding machines, mold separation devices, etc., can solve the problems of uneconomical benefits, waste of steel, slow progress in construction time, etc., to simplify the construction process and strengthen the internal structure Strength, the effect of rapid mass-production manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] After further description of the preferred embodiment of the present invention in conjunction with the following diagrams, it will become clearer.

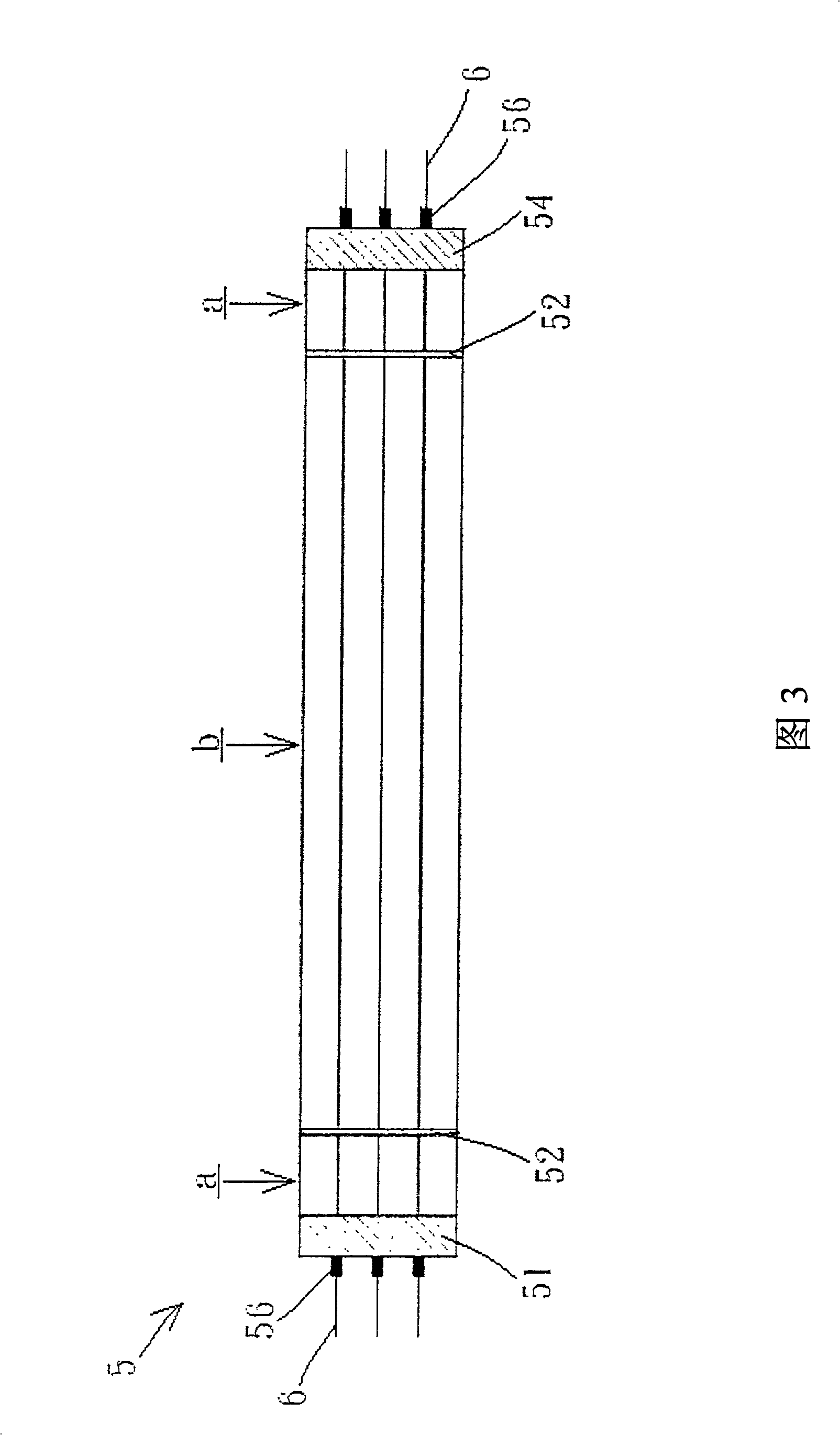

[0074] The present invention mainly uses different end molds to change the linear laying structure of steel cables inside the prefabricated part structure, so as to strengthen the structural strength of the prefabricated part structure and achieve the efficiency of rapid and mass production. Please refer to Figures 1A to 1C and Figure 1 at the same time. 2 is a schematic diagram of the appearance of the end mold body of the molding device of the present invention and a schematic diagram of the appearance of the connecting kit. It can be clearly seen from the figure that the end mold and some internal component structures used in the present invention include the front steel cable fixing Connecting end mold 51, linking kit 56, bolt 57, component size end mold 52, rear piece steel cable fixed end mold 54, wherein the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com