Luminaire and lamellae grid for this

A technology of illuminators and thin plates, which is applied in the field of illuminators, can solve problems such as shape restrictions, and achieve the effects of small material thickness, material saving, and offsetting light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

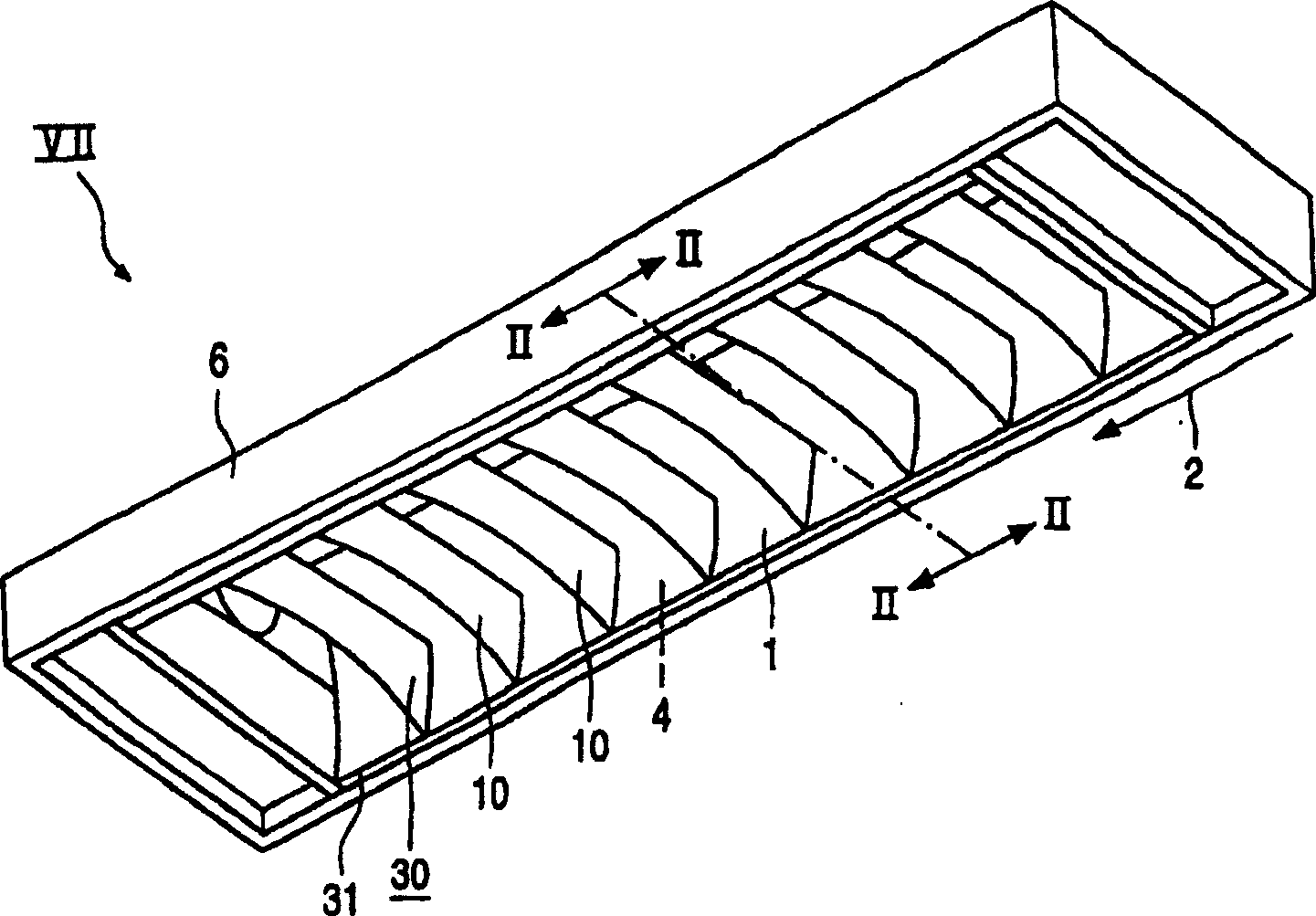

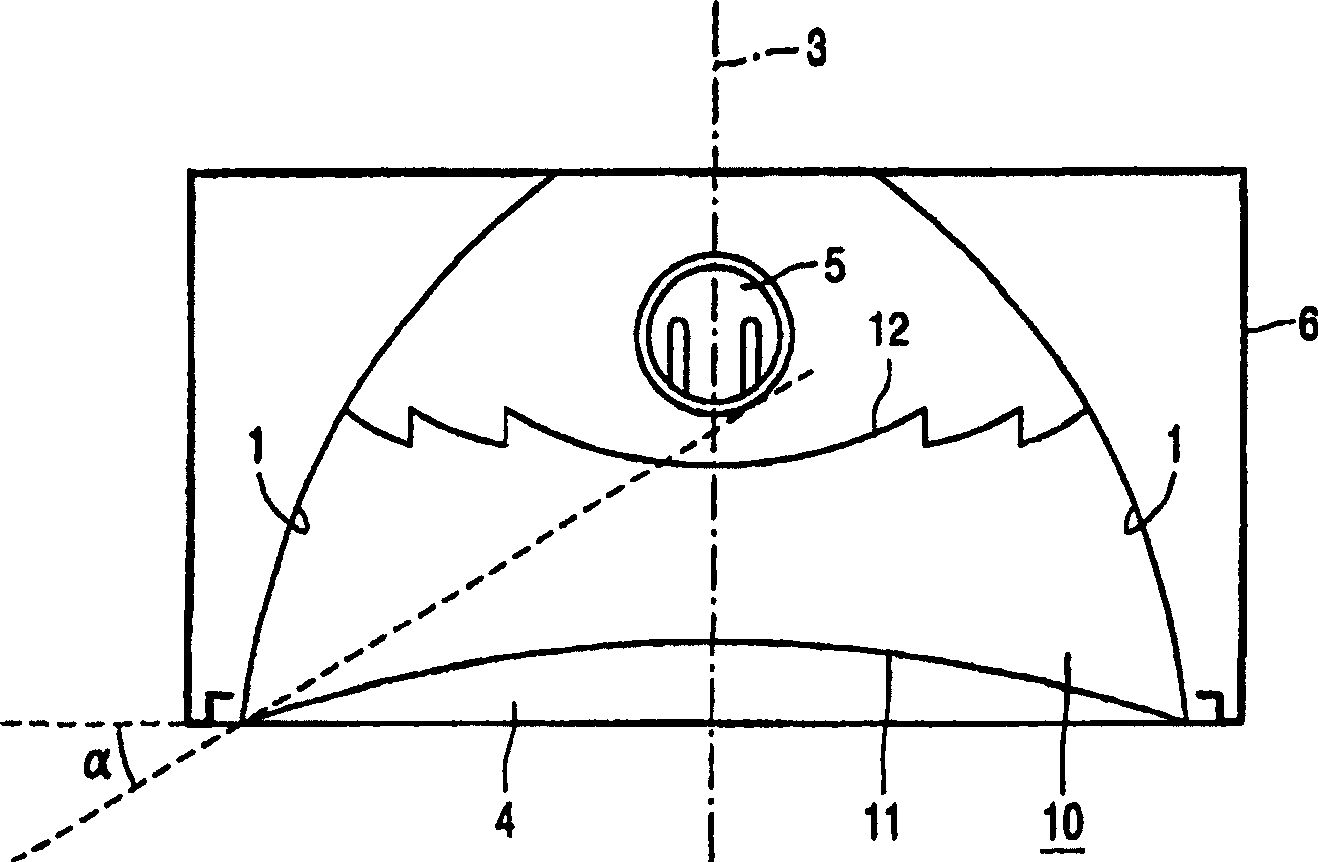

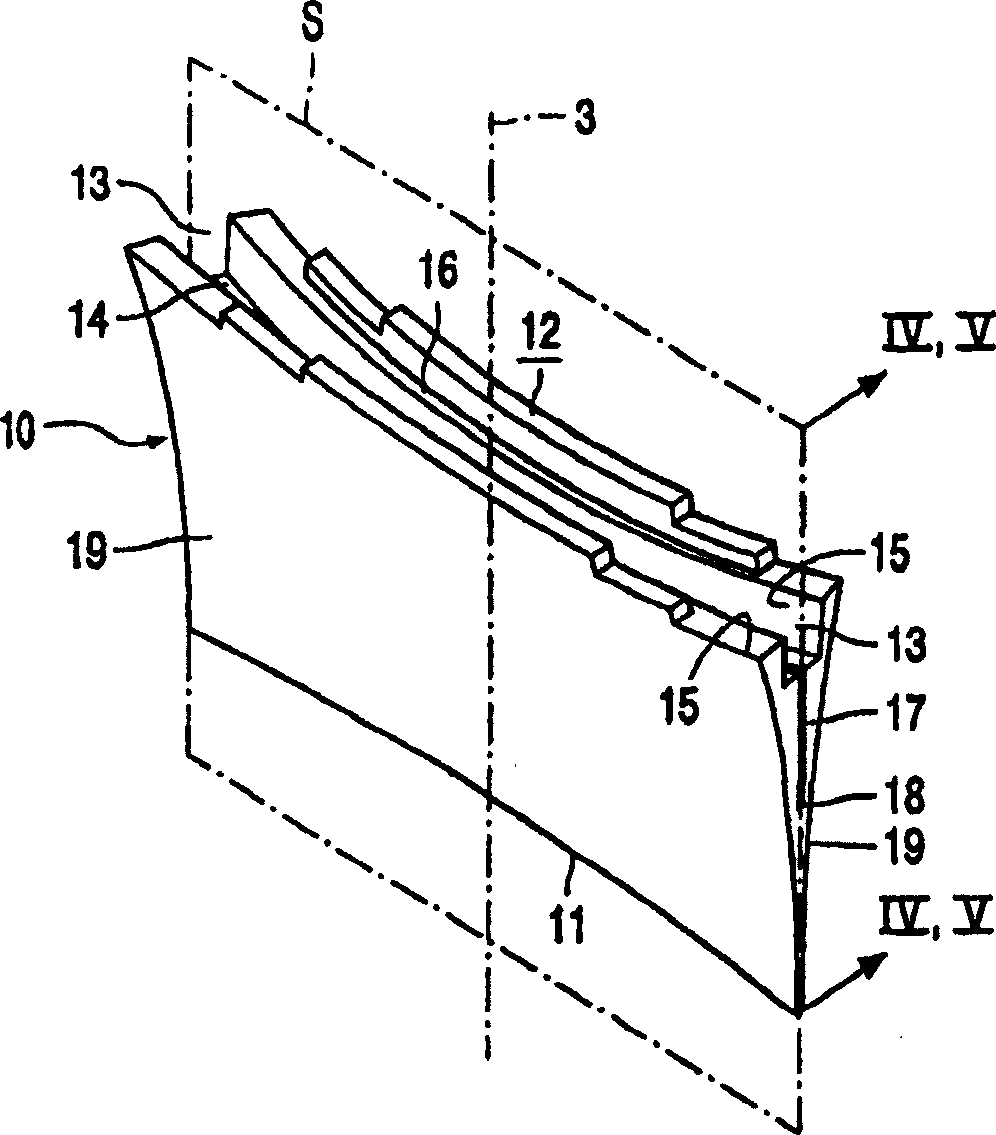

[0044] exist figure 1 and 2 , the luminaire is provided with side reflectors 1 having a longitudinal direction 2 and being mirror-symmetrical on both sides of a central plane 3 . A light emission window 4 is bounded by the side reflectors 1 and is oriented transversely to the central plane 3 . The device 5 is intended to accommodate an elongated electric lamp in the central plane 3 , in the longitudinal direction 2 of the side reflector 1 and away from the luminous emission window 4 . The device 5 is adapted to accommodate a straight tubular low pressure mercury vapor discharge vessel provided with a phosphor. like figure 2 The two identical cross-sections shown show the figure 1 Section II-II in . The device 5 is shown in this embodiment accordingly in two parts. A plurality of three-dimensional reflective sheets 10 extend transversely to the center plane between the side reflectors 1 , distributed uniformly in the longitudinal direction 2 of the side reflectors. A cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com