New type full automatic plastic bottle blowing machine

A fully automatic, plastic bottle technology, applied in the field of plastic bottle processing equipment, can solve the problems of difficult center positioning, asynchronous mold transfer, etc., to achieve the effects of smooth demoulding, overcoming high height, and accurate displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

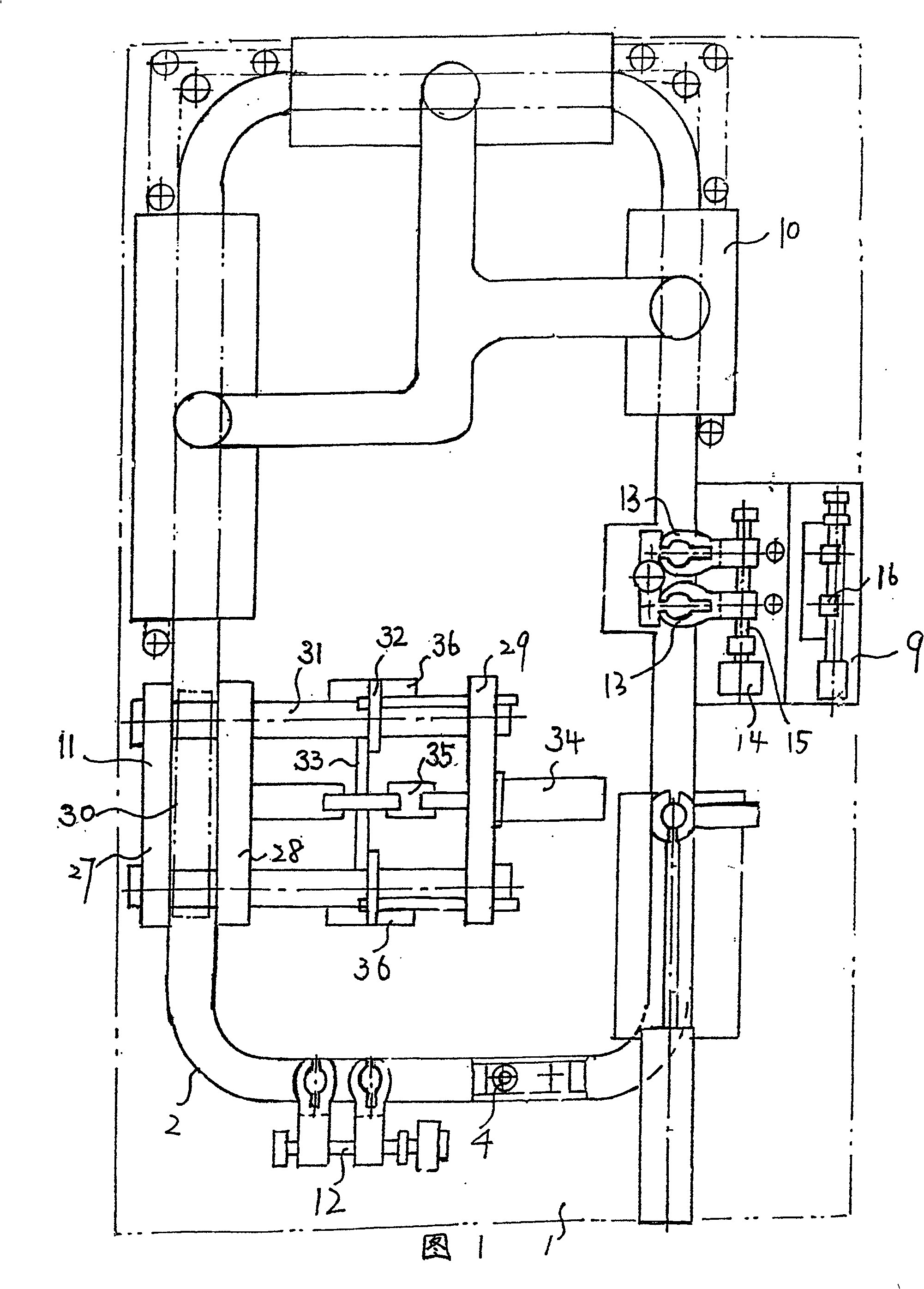

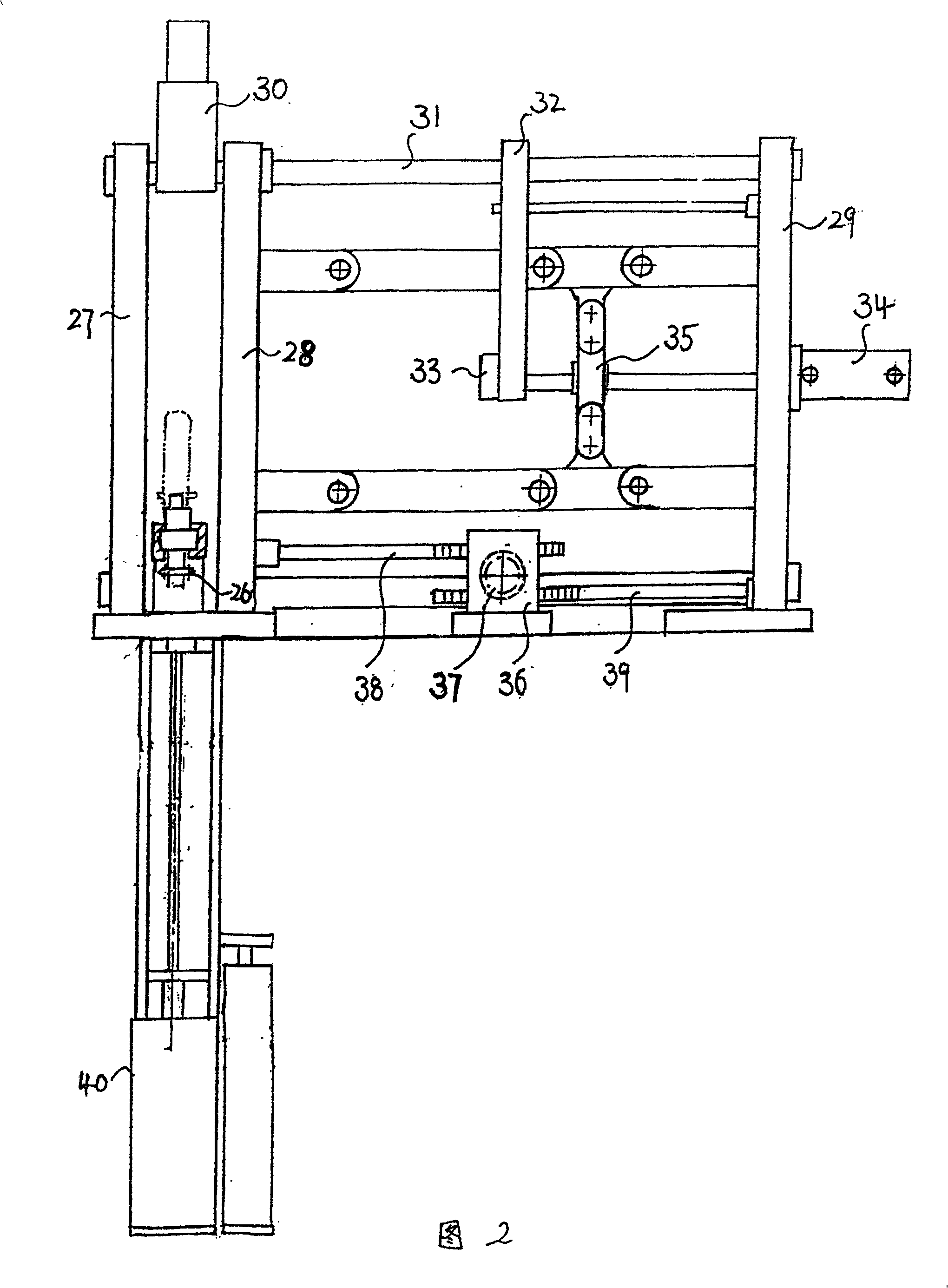

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] With reference to Fig. 1, Fig. 2, a kind of fully automatic plastic blow molding machine comprises a frame 1, and the annular conveying mechanism is installed on the frame, and the feeding device 9 of plastic bottle tube is installed on the circular conveying mechanism in sections. The heating device 10 of the bottle tube and the rotation chain mechanism of the plastic bottle tube beside the heating road, the stretch blow mold forming device 11 and the take-out device 12 of the plastic bottle, the bottle tube support seat 4 is arranged on the ring conveying mechanism, the bottle mouth of the plastic bottle tube Cooperate with the bottle tube support seat 4, the bottom of the bottle tube support seat 4 is equipped with a rotation sprocket matched with the rotation chain, and the feeding device 9 includes a feeding clamp 13, a feeding rotary cylinder 14, a rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com