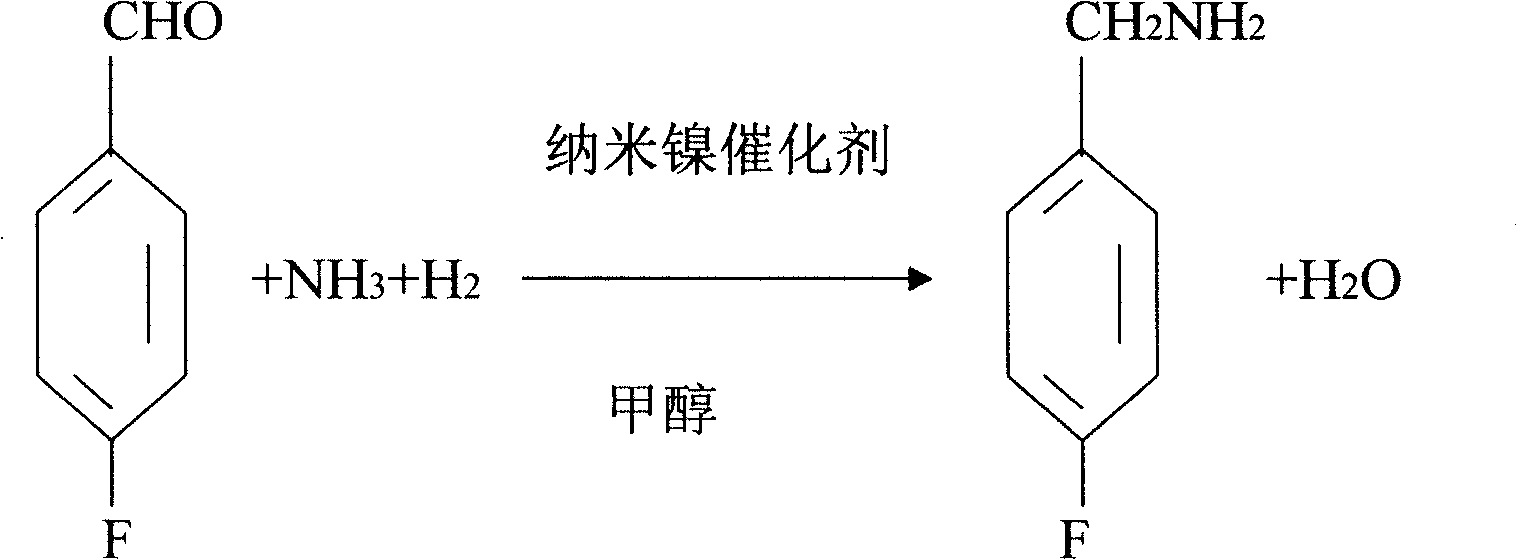

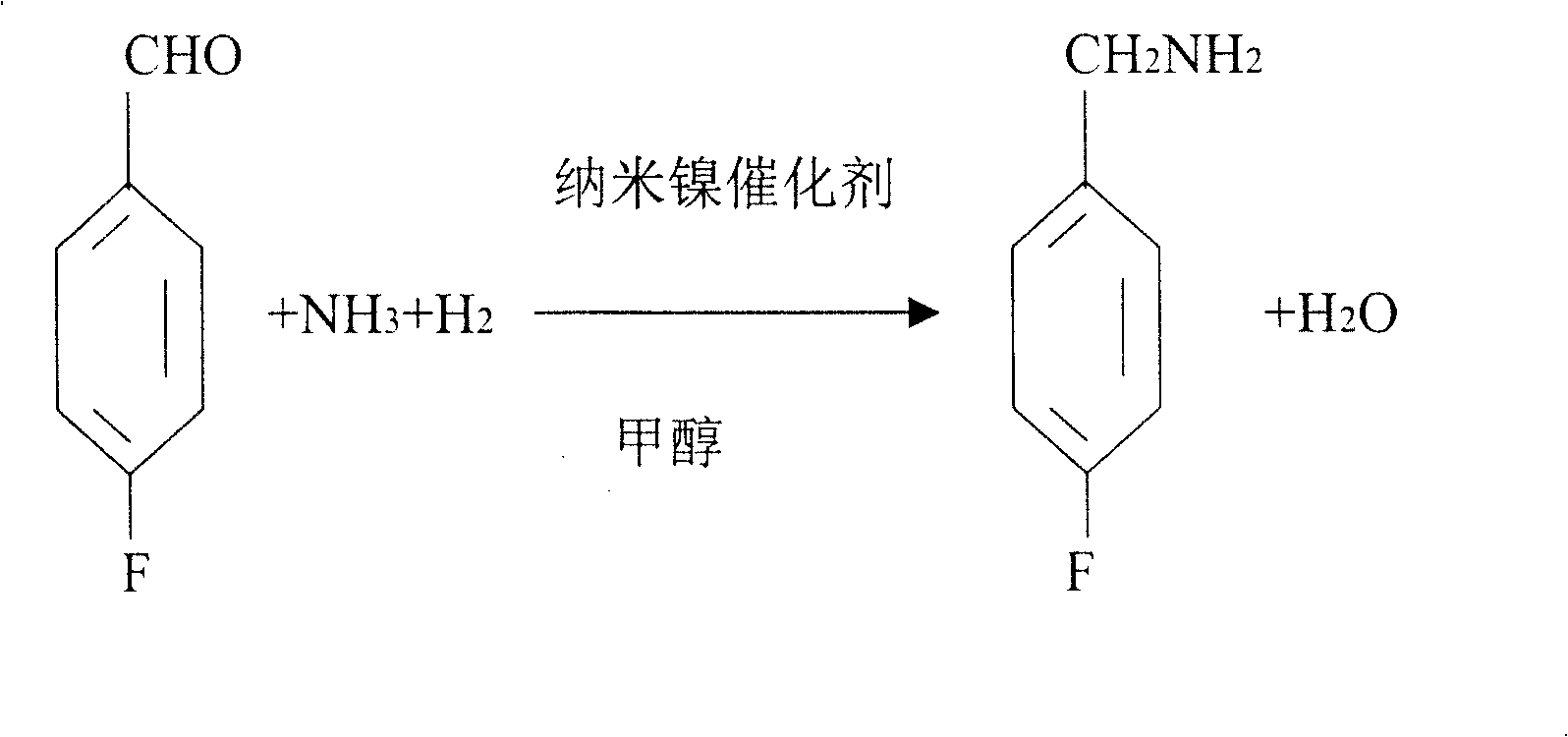

Process for preparing 4-fluorobenzylamine with nano nickel as catalyst

A technology of p-fluorobenzylamine and catalyst, which is applied in the field of preparation of p-fluorobenzylamine, can solve the problems of long reaction time, high reaction temperature and high cost, and achieve the effects of fast reaction speed, simple operation and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation steps of the present invention are as follows:

[0015] Step 1: be that 99% p-fluorobenzaldehyde 300Kg, anhydrous methanol 150Kg, nano-nickel catalyst 0.6Kg drop into 1000L autoclave, pass into liquid ammonia 30Kg, its feed intake weight ratio is: p-fluorobenzaldehyde: methyl alcohol: Liquid ammonia=1: 0.5: 0.10; the consumption of nano-nickel catalyst is 0.2% of the consumption of p-fluorobenzaldehyde.

[0016] Step 2: Heat up the temperature to about 70°C with steam under the stirring state, and then introduce pressure hydrogen into the reaction kettle, the pressure is 1Mpa-3Mpa;

[0017] Step 3: make the reaction fully until no hydrogen is absorbed, the reaction time is about 4 hours, and after the reaction stops, it is incubated for about 1 hour. After the reaction mixture is cooled, it is pressed into the fine-setting kettle, and the nano-nickel catalyst is separated by the fine-setting method to obtain crude p-fluorobenzylamine containing methanol...

Embodiment 2

[0020] Step 1: be that 99% p-fluorobenzaldehyde 300Kg, anhydrous methanol 300Kg, nano-nickel catalyst 1.8Kg drop into 1000L autoclave, pass into liquefied ammonia 45Kg, its feed intake weight ratio is: p-fluorobenzaldehyde: methyl alcohol: Liquid ammonia=1:1:0.15; the consumption of nano-nickel catalyst is 0.6% of the consumption of p-fluorobenzaldehyde.

[0021] Step 2: Stir and heat up to about 100°C, then feed hydrogen under pressure into the reactor, the pressure is 1Mpa-3Mpa;

[0022] Step 3: Make the reaction fully until no hydrogen is absorbed. The reaction time is about 3 hours. After the reaction stops, it is kept warm for 1 hour. The crude product of p-fluorobenzylamine in methanol;

[0023] Step 4: put the crude product of p-fluorobenzylamine obtained in step 3 into a rectification kettle for rectification, deamination before 80°C and recover methanol, dehydrate at 100°C, collect p-fluorobenzylamine at 186°C-190°C, and obtain a content greater than 99% The product...

Embodiment 3

[0025] Step 1: be that 99% p-fluorobenzaldehyde 300Kg, anhydrous methanol 600Kg, nano-nickel catalyst 3Kg drop into 1000L autoclave, pass into liquid ammonia 60Kg, its feed intake weight ratio is: p-fluorobenzaldehyde: methyl alcohol: liquid Ammonia=1: 2: 0.2; the consumption of nano-nickel catalyst is 1% of the consumption of p-fluorobenzaldehyde.

[0026] Step 2: Stir and heat up to 120°C, then feed hydrogen under pressure into the reactor, the pressure is 1Mpa-3Mpa;

[0027] Step 3: Make the reaction fully until no hydrogen is absorbed. The reaction time is about 1 hour. After the reaction is stopped, it is incubated for about 1 hour. After the reaction mixture is cooled, it is pressed into the fine-setting kettle, and the nano-nickel catalyst is separated by the fine-setting method to obtain crude p-fluorobenzylamine containing methanol;

[0028] Step 4: put the crude product of p-fluorobenzylamine obtained in step 3 into a rectification kettle for rectification, deaminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com