Device for detecting three-axle parallel of large photoelectric monitoring equipment using thermal target technology

A technology for parallelism detection and measurement and control equipment, applied in the direction of optical devices, measuring devices, optical instrument testing, etc., can solve the problem that the frequency doubling technology cannot be used, the background technology cannot directly measure the parallelism error between the laser and the infrared optical axis, and is not applicable Field measurement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

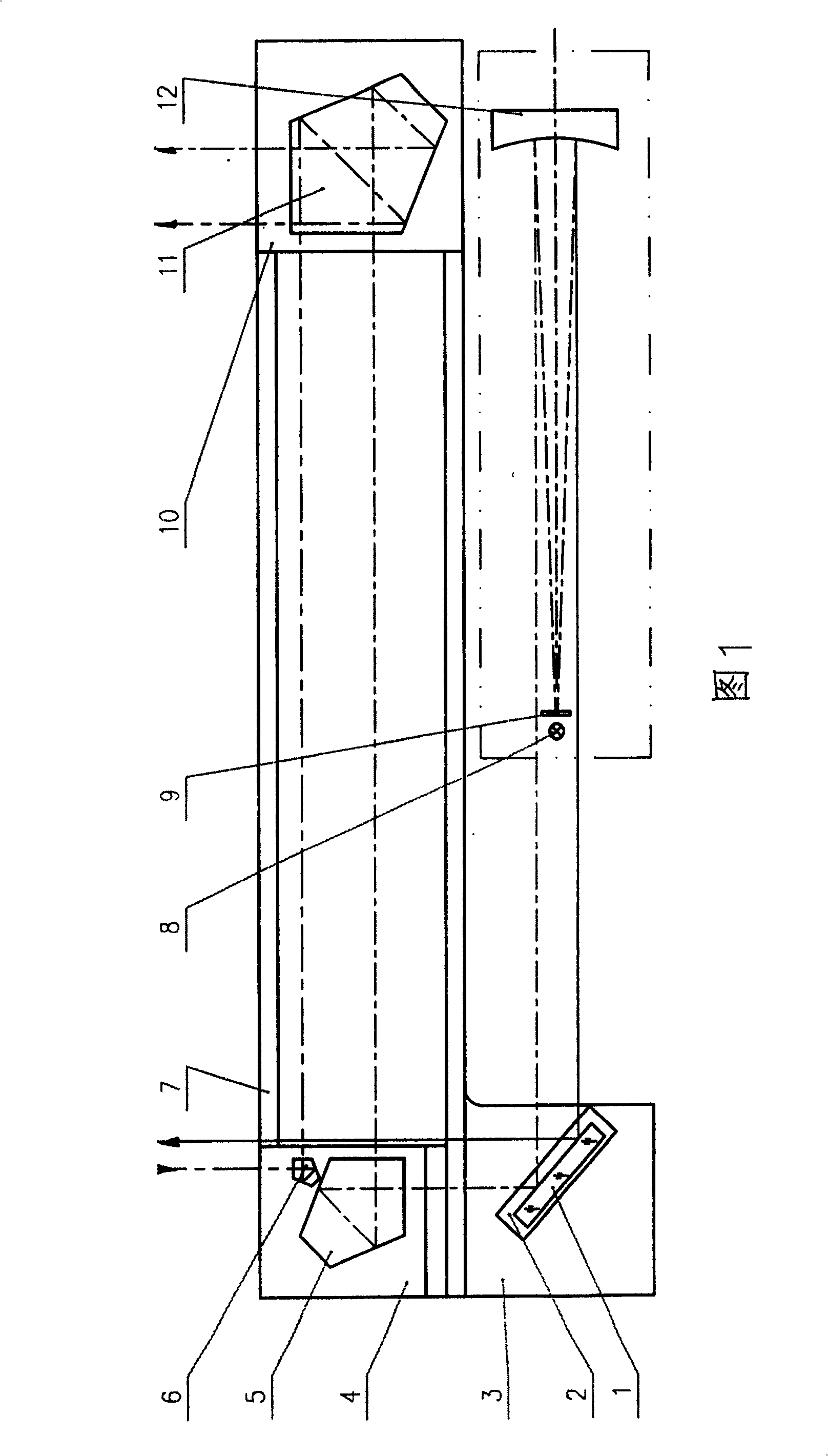

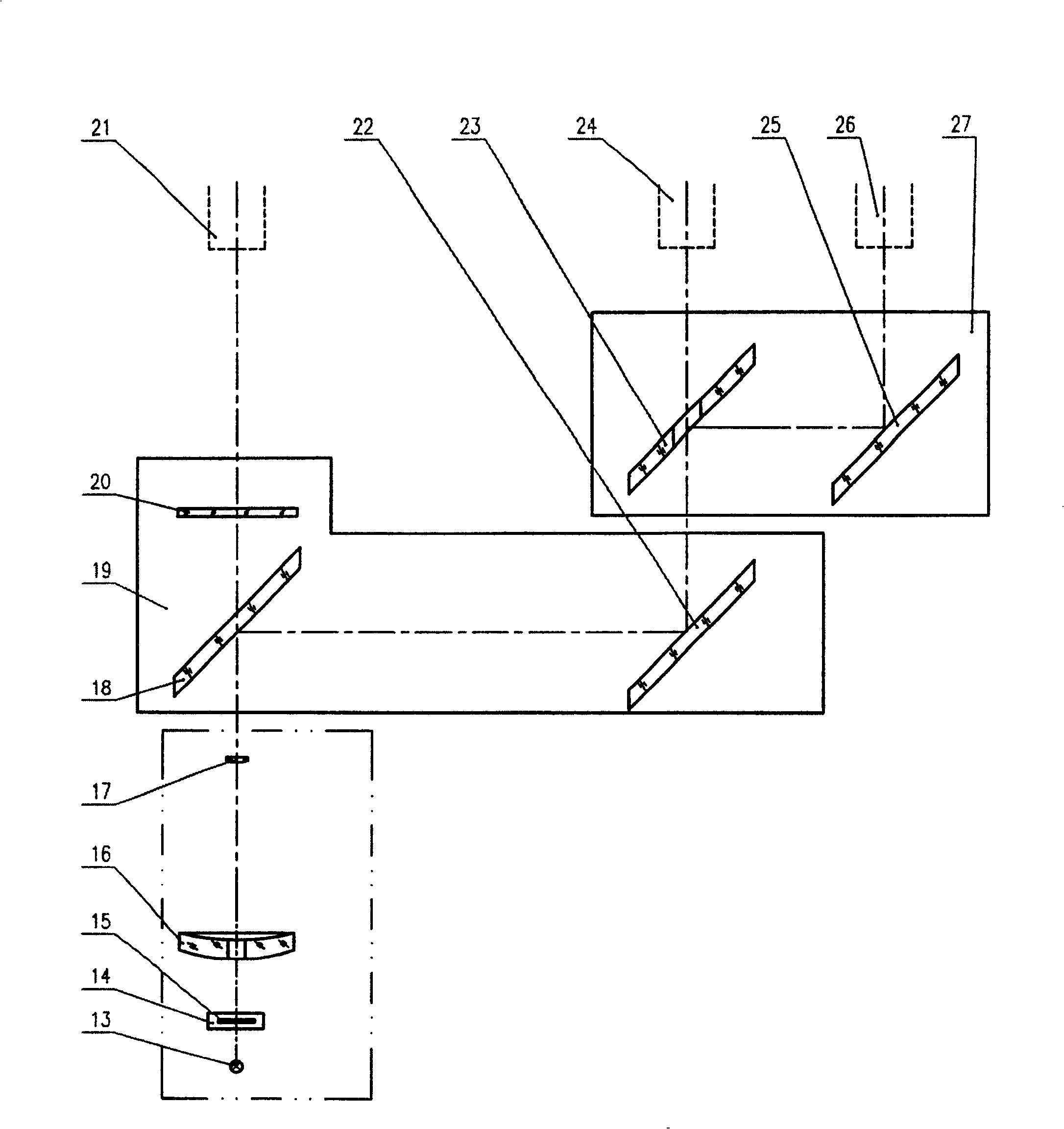

[0015] The invention according to figure 2 The structure shown is implemented, wherein the light source 13 is an iodine-tungsten lamp, which has a wide spectral range, and the thermal target slider 14 can move left and right, and the moving distance is greater than the line field of view of the collimated optical path system, and the thermal target cannot be out of alignment. The field of view of the straight light path; there is a star point hole in the center of the hot target. When the light source is turned on, the star point hole is located on the optical axis of the collimated light path. When the light source is turned off, the star point hole on the hot target moves to the collimated light path. Outside the field of view, the area of the hot target should be able to meet the requirements of converging the laser energy emitted by the laser system laser of the tested instrument and absorbing the laser energy to generate hot spots; The optical aperture and focal length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com