Centrifugal fan

A technology of centrifugal fan and fan blade, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., which can solve the problem of the overall airflow characteristics of the combined centrifugal fan 2 and the cost of materials. Waste and other issues, to achieve the effect of increasing wind pressure, improving airflow characteristics, and reducing airflow counterflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

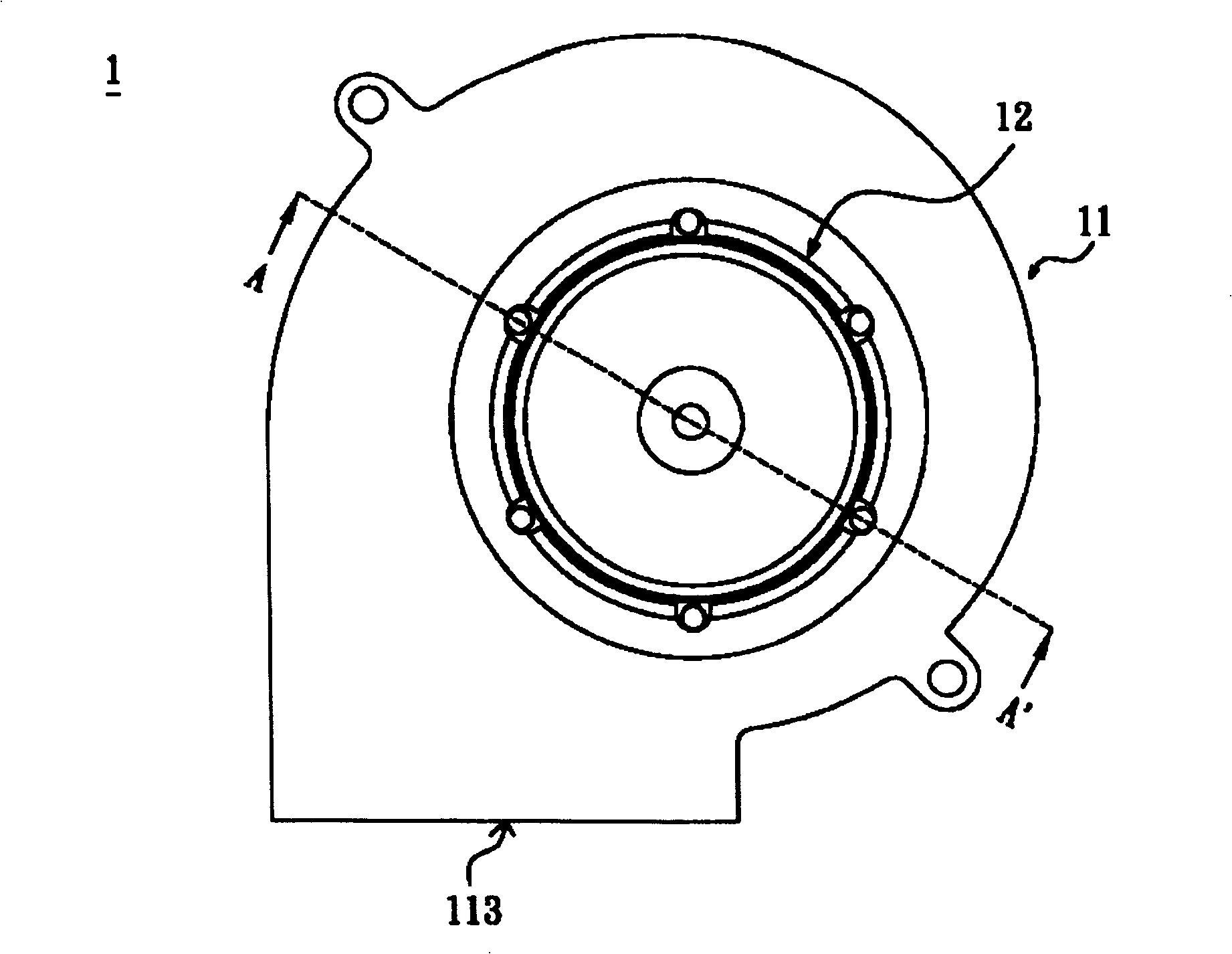

[0045] FIG. 5 is a schematic top view of the centrifugal fan according to the first embodiment of the present invention. As shown in FIG. 5 , the centrifugal fan 3 includes a casing 31 and a plurality of impellers 32 .

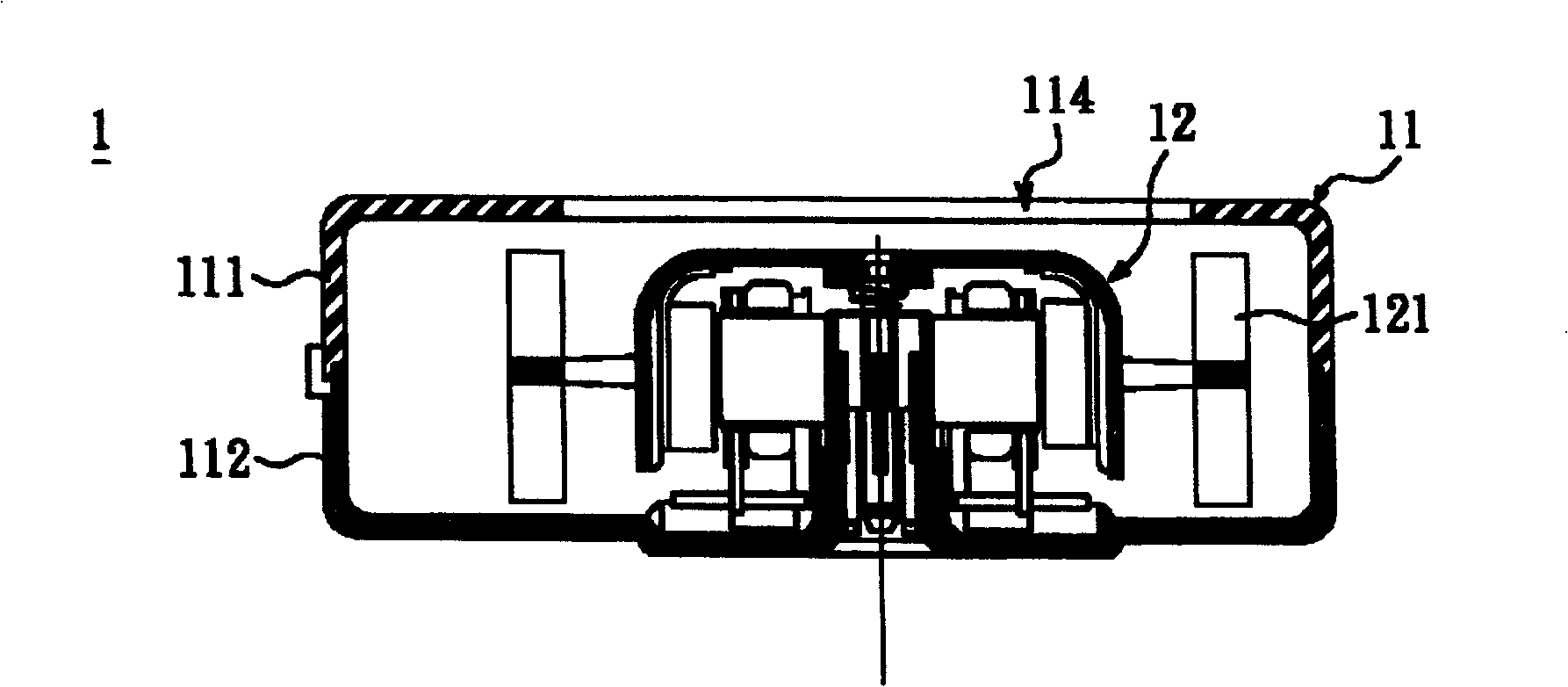

[0046] Figure 6 is a schematic cross-sectional view of Figure 5 along the line BB', as shown in Figure 6, in this embodiment, the housing 31 has two air inlets 311, and each air inlet 311 corresponds to each impeller respectively 32. In addition, the shell system has an air outlet 312 , so that the air flow enters the impeller 32 through multiple air inlets 311 , is driven by the blades of the impeller 32 , and then is sent out through a single air outlet 312 .

[0047] The impeller 32 is accommodated in the casing 31 , and there is a flow collecting channel 33 between the impeller 32 and the casing 31 , and the impeller 32 has a plurality of fan blades 321 respectively. Wherein, the casing 31 has a peripheral portion 312 at the air inlet 311, and the periph...

no. 2 example

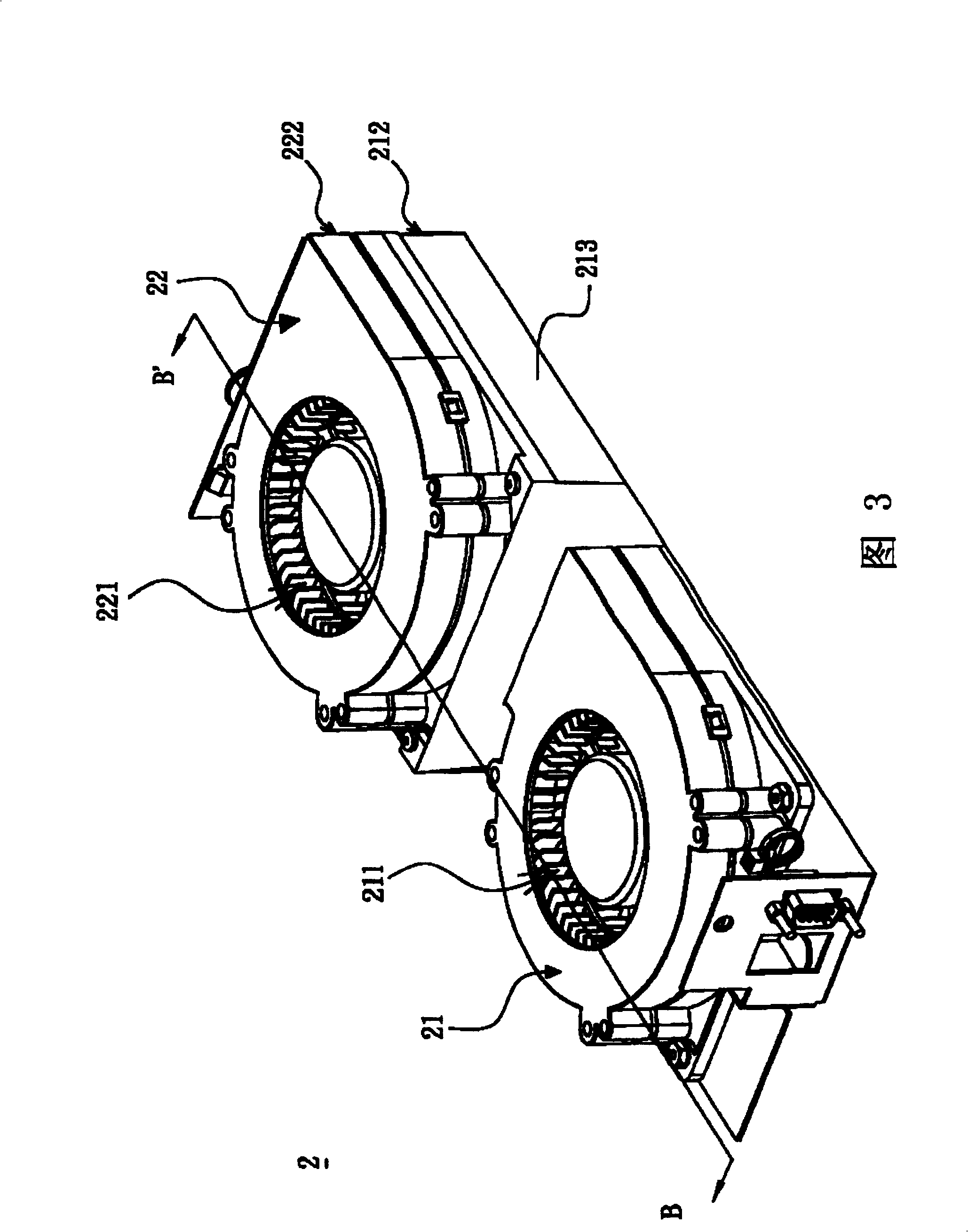

[0050]Next, please refer to FIG. 7 , which is a schematic top view showing a centrifugal fan according to a second embodiment of the present invention. As shown in FIG. 7 , the centrifugal fan 4 includes a casing 41 and two impellers 42 . A plurality of impellers 42 are accommodated in the casing 41 , and a flow collecting passage 43 is provided between the impellers 42 and the casing 41 .

[0051] As shown in Figure 7, the casing 41 has an air outlet 412, the two impellers 42 are arranged in a straight line, and the center line of the impeller 42 and the section of the air outlet 412 have an included angle Θ, wherein the included angle Θ is an acute angle. That is to say, the configuration of the two impellers 42 is asymmetrically arranged in the casing 41, which can reduce the phenomenon that the airflow driven by each impeller 42 interferes with each other, so a plurality of impellers 42 are arranged asymmetrically in the casing. In the body 41, the decline of the overall...

no. 3 example

[0057] Figure 11 It is a schematic top view of a centrifugal fan according to the third embodiment of the present invention. Such as Figure 11 As shown, the two impellers 42 in the centrifugal fan 4 are arranged in a straight line, and the angle between the center line of the plurality of impellers 42 and the section of the air outlet 412 is about 90 degrees.

[0058] Centrifugal fan 4 also can have more than two impellers 42, such as Figure 12 as shown, Figure 12 It is a schematic top view of another centrifugal fan according to the third embodiment of the present invention. Please also refer to Figure 11 and Figure 12 , the centrifugal fan 4 has three impellers 42 , and a blocking member 44 is arranged between every two impellers 42 . There is a common collector flow passage 43 among the plurality of impellers 42 , and since the centrifugal fan 4 has a plurality of impellers 32 connected in series, the overall performance of the centrifugal fan 4 can be increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com