Mixed dust separating device

A kind of dust removal device and hybrid technology, applied in the direction of combination device, steam flow control, electrode structure, etc., can solve the problems of dust removal filter damage, increase of filter pressure loss, failure to work normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A hybrid dust removal device according to a preferred embodiment of the present invention will be described below.

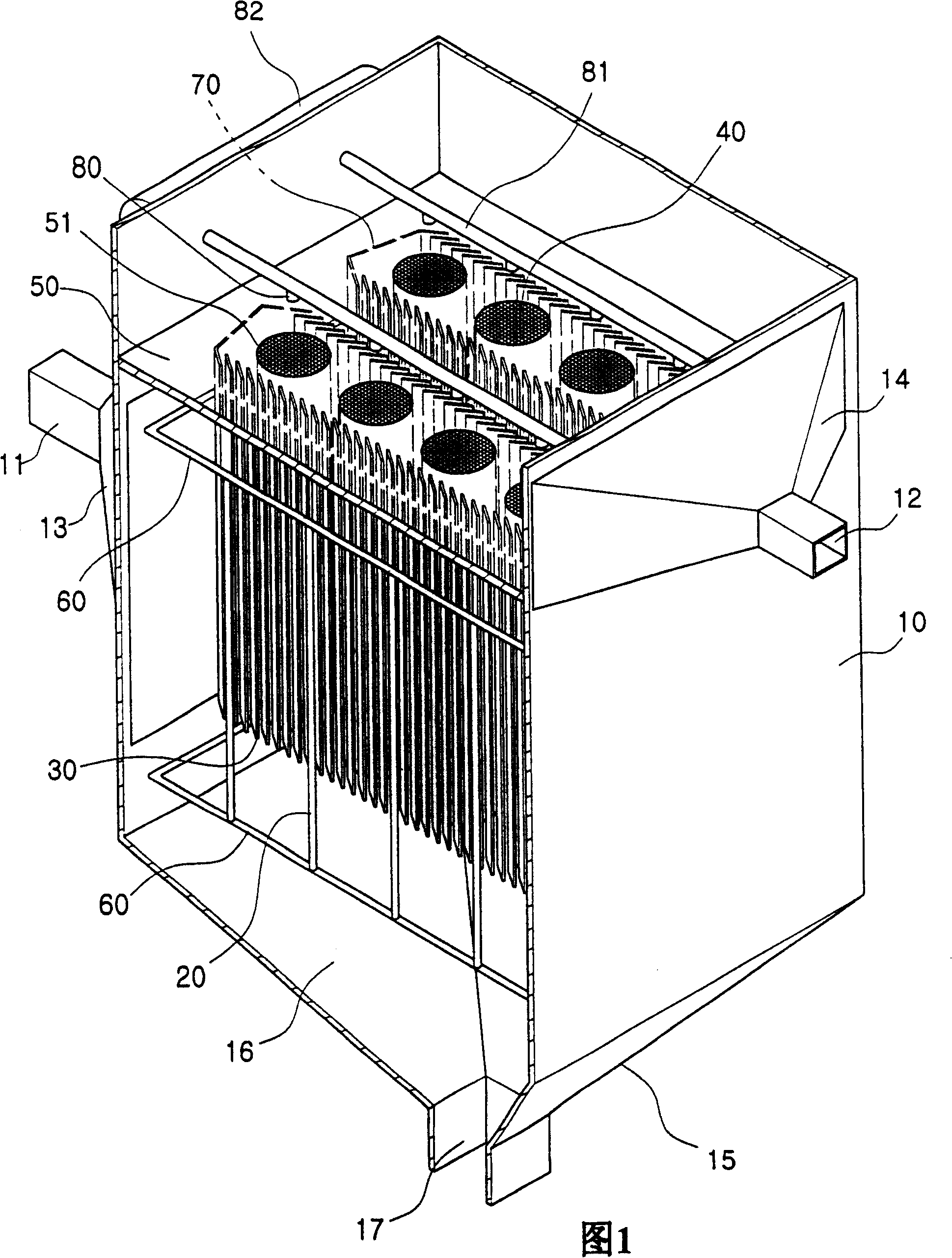

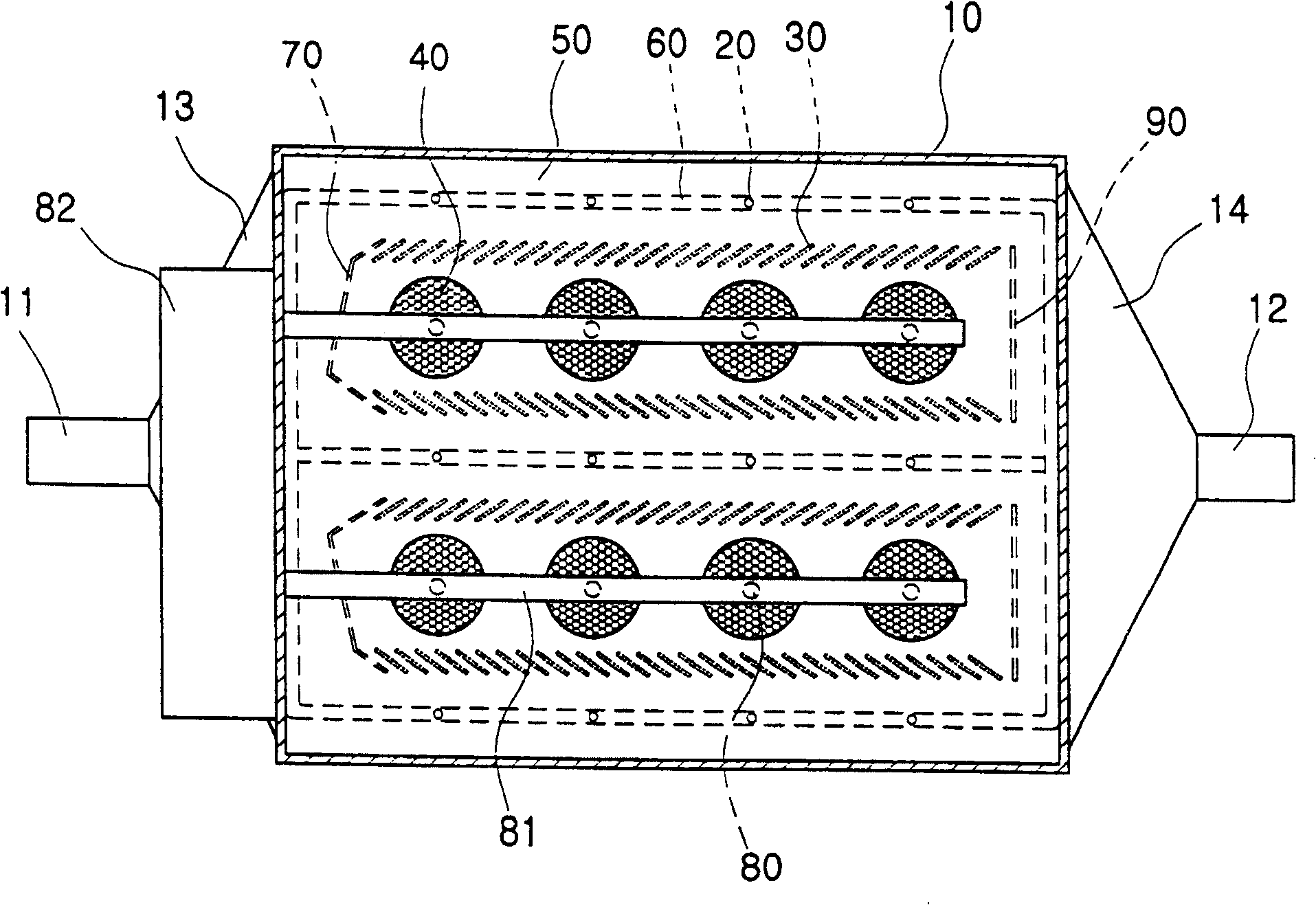

[0033] Fig. 1 is an open perspective view showing the hybrid dust removal device of the preferred embodiment.

[0034] As shown in FIG. 1 , the hybrid dust removal device includes a rectangular housing 10 . The rectangular housing 10 has an inflow channel 11, which is connected with a section of inflow expander pipe 13, which is arranged at the lower part 10 of one side of the housing 10; and has an outflow channel 12, which is connected with a section of outflow expander pipe The flow reducer 12 is connected, and the reducer is arranged on the upper part of the other side of the casing 10 .

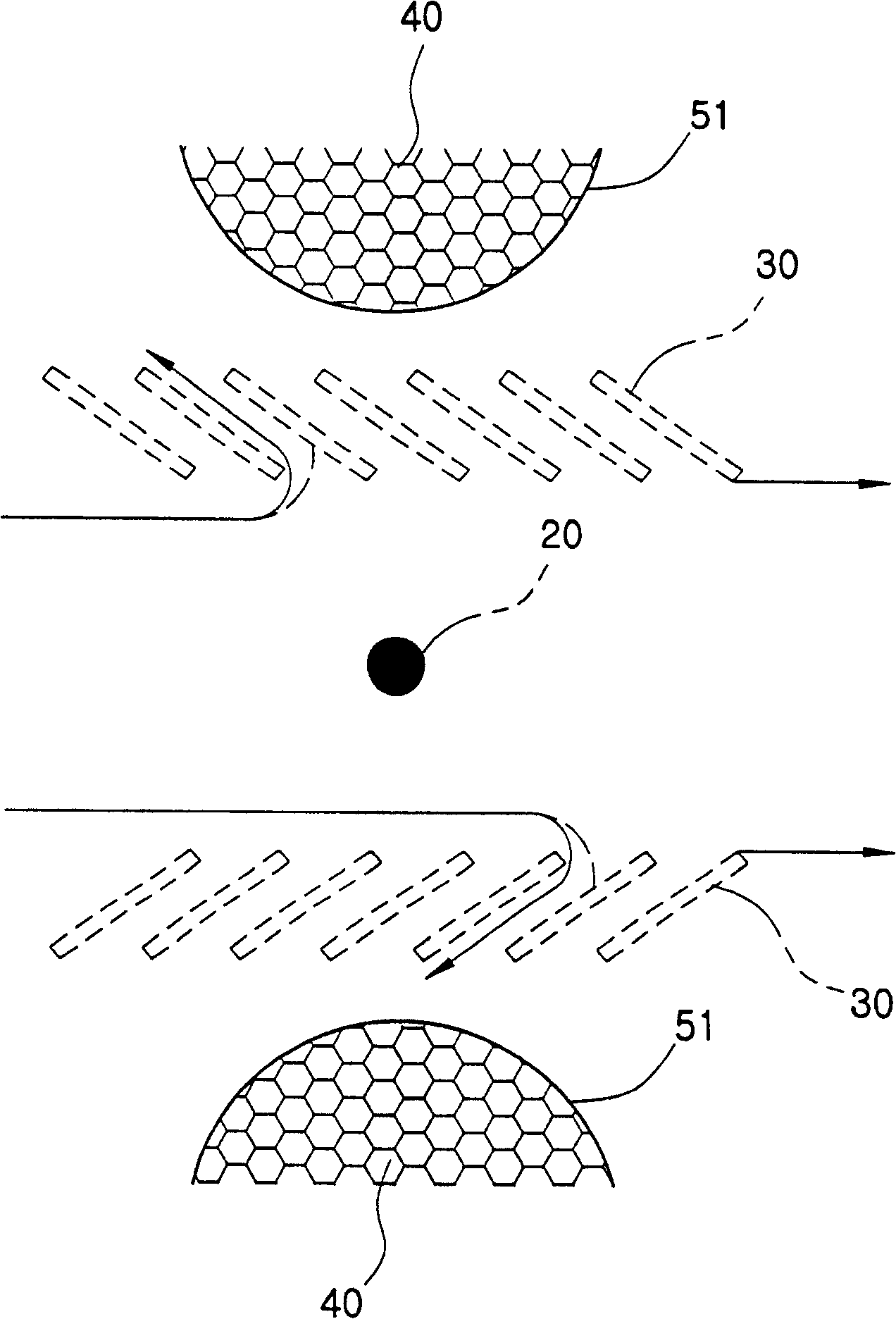

[0035] Inside the housing 10, a horizontal partition 50 is provided with a plurality of filter mounting holes 51 on the partition. A plurality of dust removal filters 40 are respectively inserted into these mounting holes 51 , and the filters 40 extend downward fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com