High-pressure homogeneous device

A high-pressure homogenization and structuring technology used in fluid mixers, dissolvers, mixers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned structures, features and functions of the present invention more comprehensible, several preferred embodiments are given and further described in detail as follows in conjunction with the accompanying drawings.

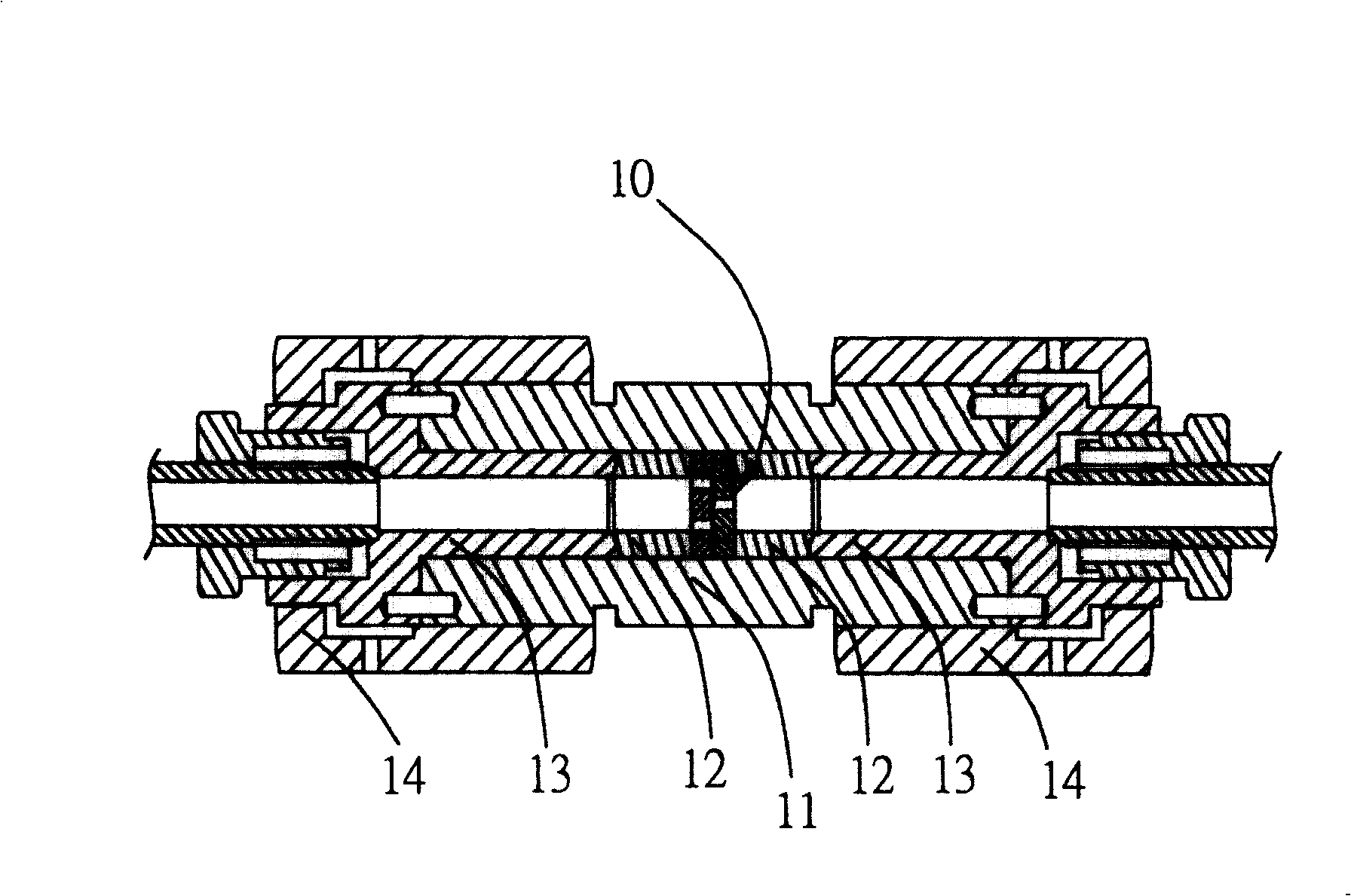

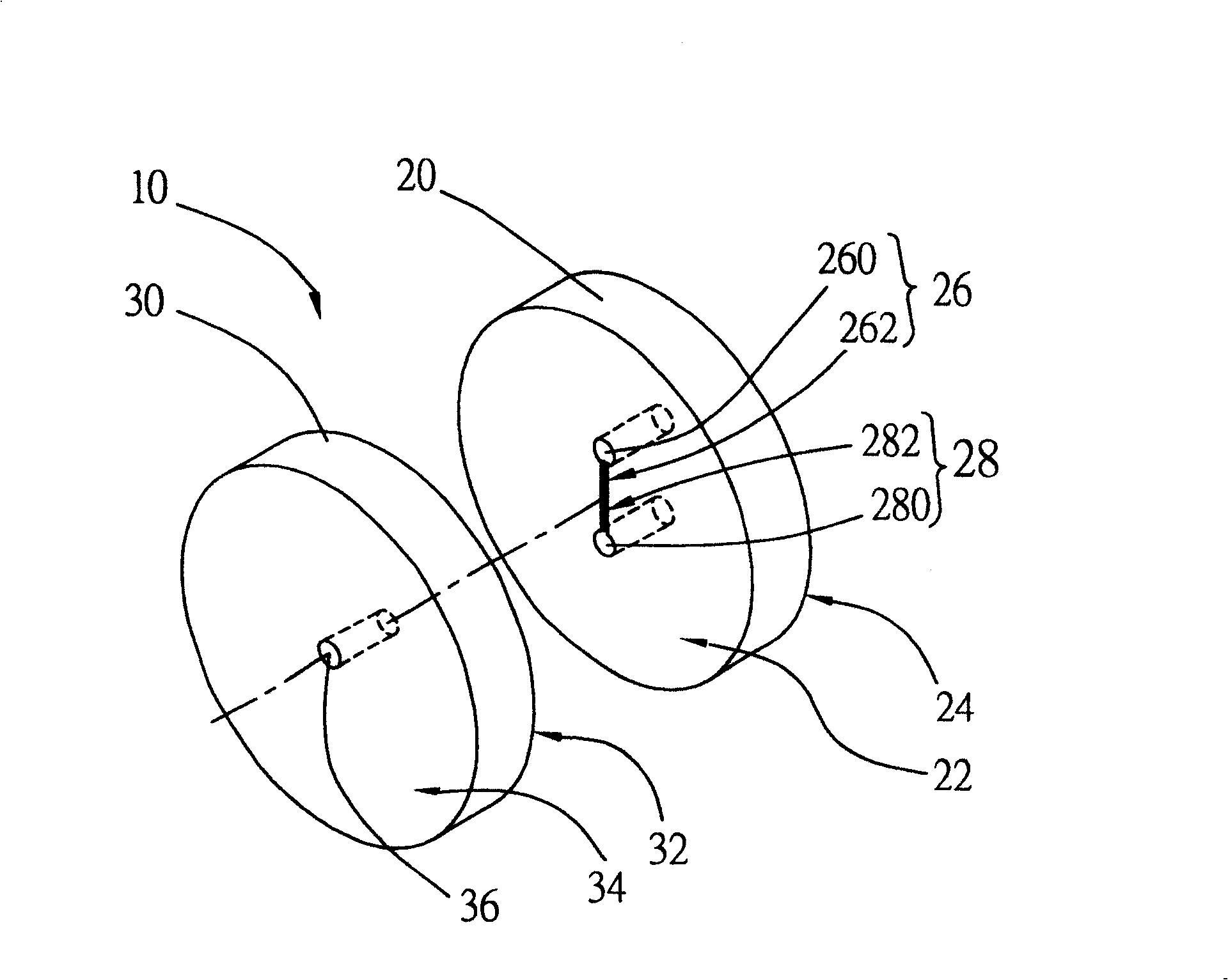

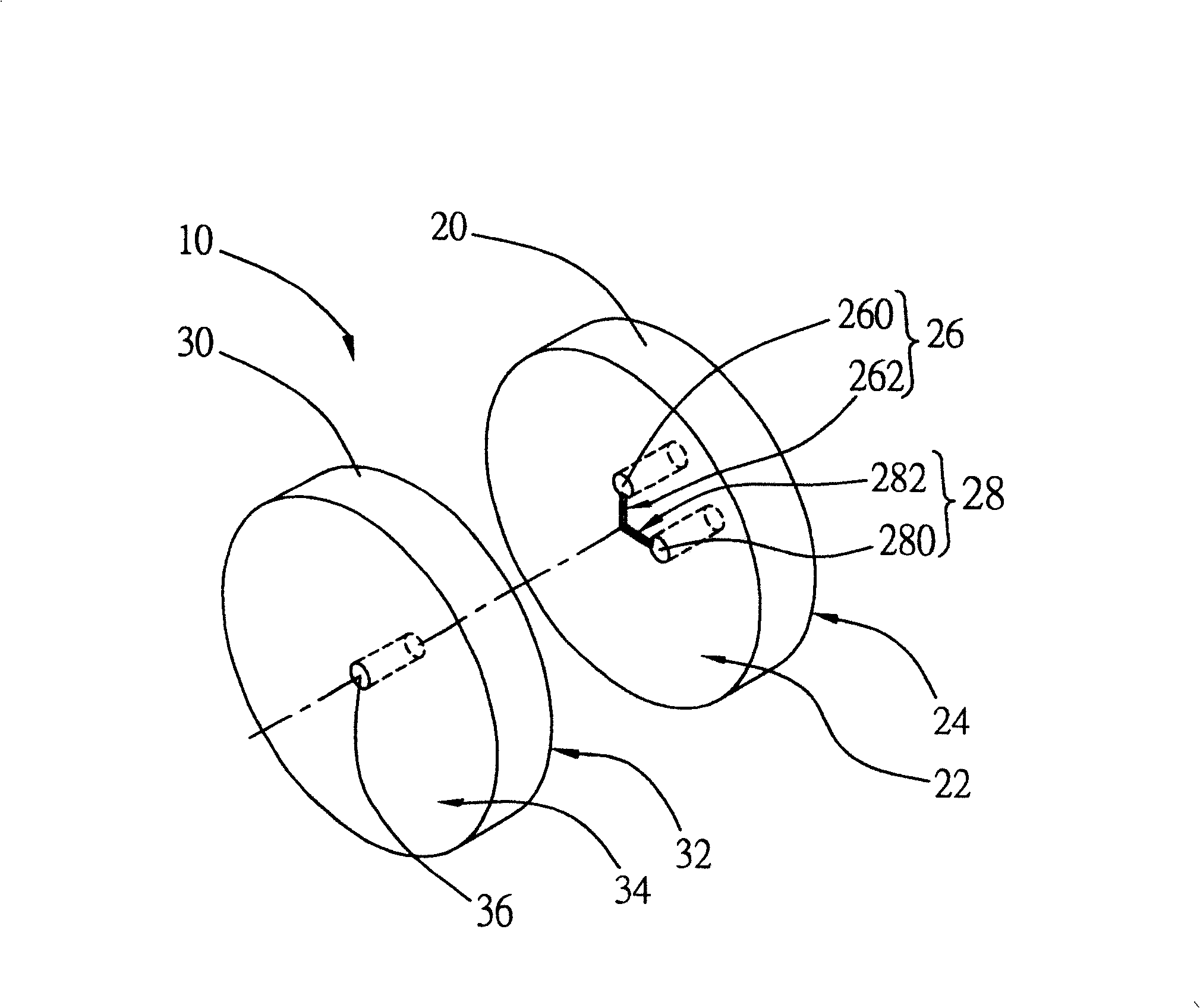

[0034] See first figure 1 , 2 , the flow guiding structure 10 disclosed in the present invention is composed of an inlet component 20 and an outlet component 30 that can be closely combined with each other. When in use, it is placed in a tubular positioning assembly 11, the two ends of which are respectively supported by a sleeve 12 and a connecting piece 13, and the two ends of the positioning assembly 11 are respectively provided with a locking assembly 14 for Each sleeve pipe 12 and connector 13 are pressed against each other by two ends.

[0035] The introduction assembly 20 has: a first inner end surface 22 and a first outer end surface 24, at least two inflow units (26, 28) are arranged at the central part of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com