Electromagnetic oven

A technology of induction cooker and furnace cavity, which is used in household stoves/stoves, electric heating fuel, household heating, etc. It can solve the problems of poor cooling effect, shorten the service life of circuit boards, affect the appearance and other problems, achieve reasonable and meticulous organization, and improve heat dissipation. The effect, the effect of less wind waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

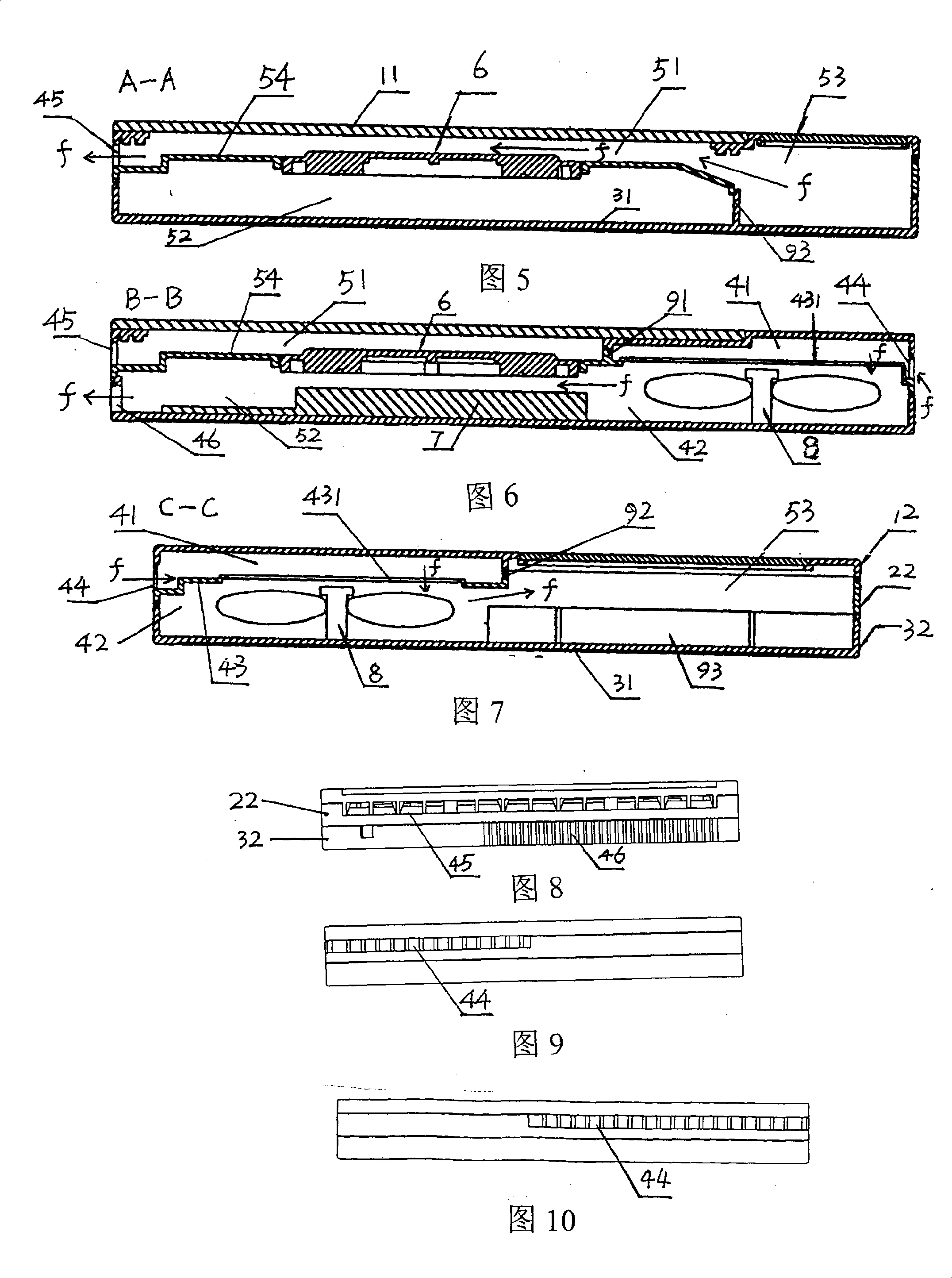

[0033] figure 1 , Fig. 2, Fig. 3, the shell of the induction cooker shown in Fig. 4 is formed by combination of upper shell, middle shell and lower shell, wherein the upper shell is assembled by microcrystalline plate 11, upper side plate 12, glass plate 13, and lower shell The bottom plate 31 and the lower side plate 32 are integrally formed, the middle shell is also provided with the middle side plate 22, the upper side plate 12, the middle side plate 22, and the lower side plate 32 are assembled to form the side wall of the whole induction cooker, the upper shell, The middle shell and the lower shell are enclosed to form a furnace cavity.

[0034] Figure 4, Figure 5, Figure 6, Figure 13 As shown, the furnace chamber is divided into a fan chamber and a main chamber, and the main chamber is further divided into an upper main chamber 51, a lower main chamber 52, and an air guide chamber 53, the upper main chamber 51 is located above the lower main chamber 52, and the glass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com