Method and device for measuring related parameter of underwater laser shock formation

A technology of impact forming and underwater laser, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of insufficient consideration of the impact, and achieve the effect of overcoming the narrow linear zone and the difficulty of high pressure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

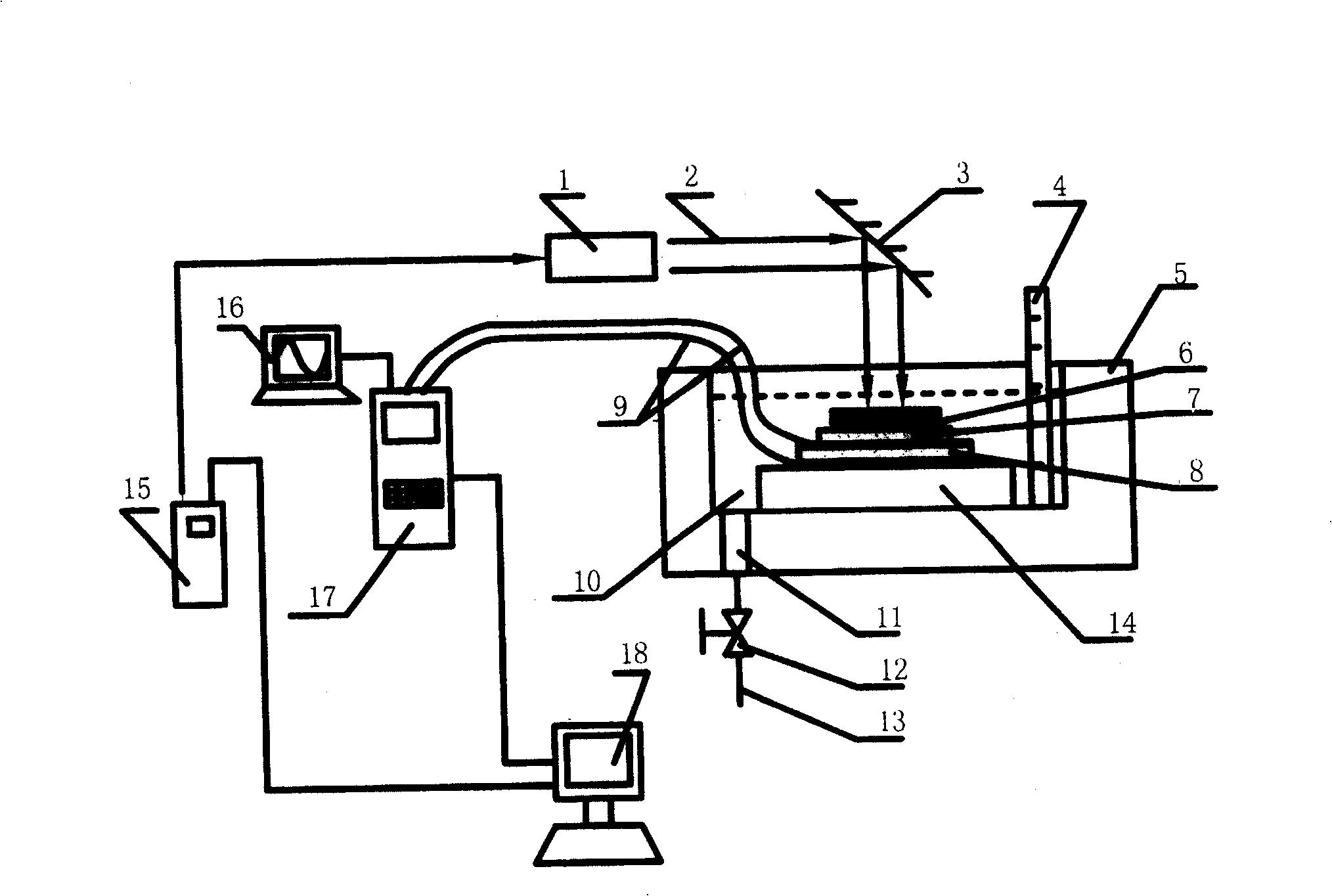

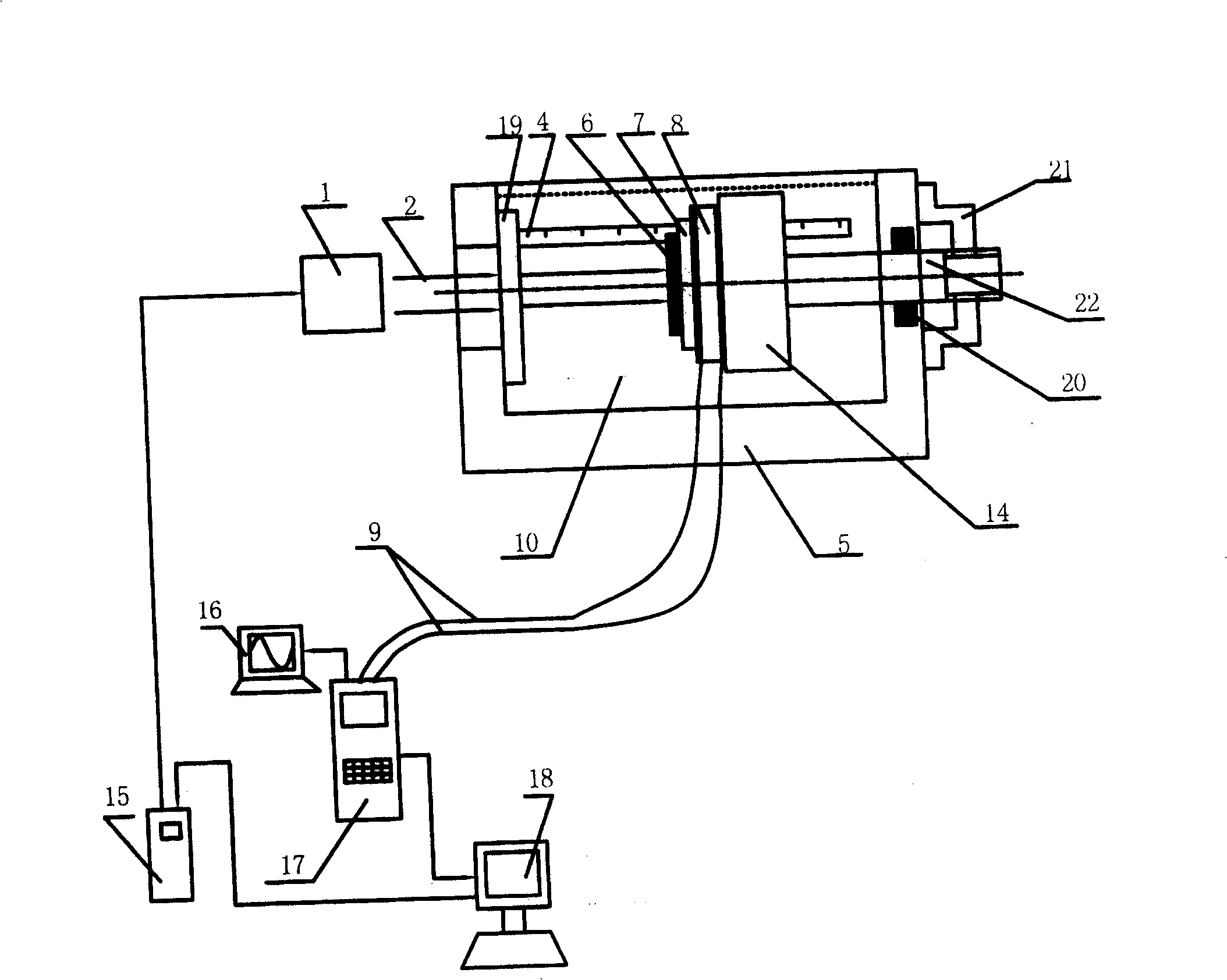

[0025] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The device for implementing the method of the present invention includes a laser generator 1 , a laser generator control system 15 , a water film thickness adjustment system, a pressure detection system, a constrained layer and an absorbing layer material 6 . Wherein the pressure detection system is composed of a sensor protective film 7, a pressure sensor 8, a base 14, a wire 9, a pressure detection device 17, an oscilloscope 16, and a microcomputer 18. For the detection of the influence of the free water film thickness on the shock wave intensity, the water film thickness adjustment system is composed of a water tank 5 , a drain hole 11 , a drain pipe 13 , and a drain valve 12 , and the constraint layer is water 10 . For the detection of the influence of the thickness of the constrained wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com