High strength panel

A panel and floor technology, which is applied to local raised floors, building components, buildings, etc., can solve the problems of large vertical and horizontal arrangement interval of reinforcing ribs 206, reduced supporting force, accelerated damage and cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, floor panels according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

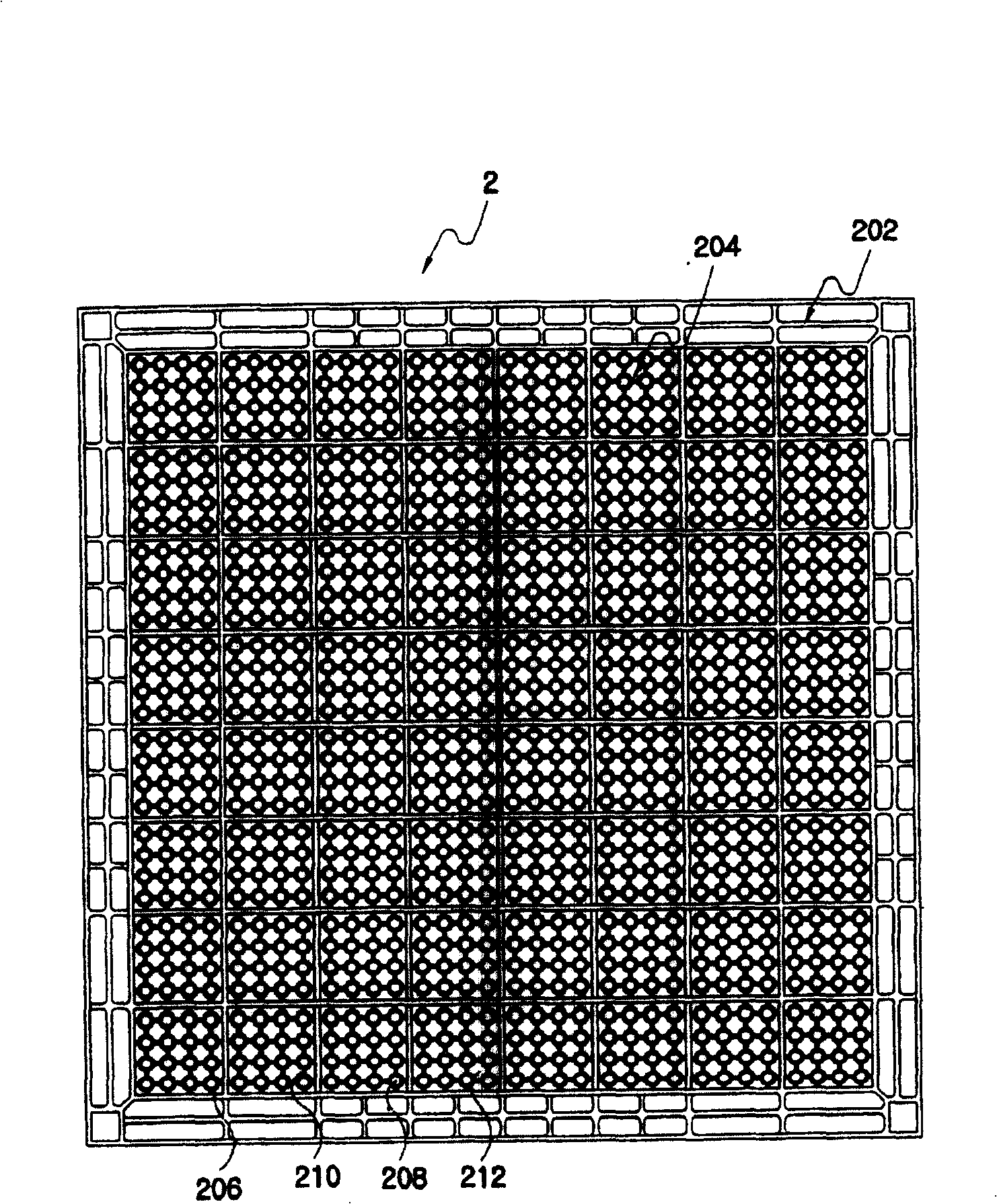

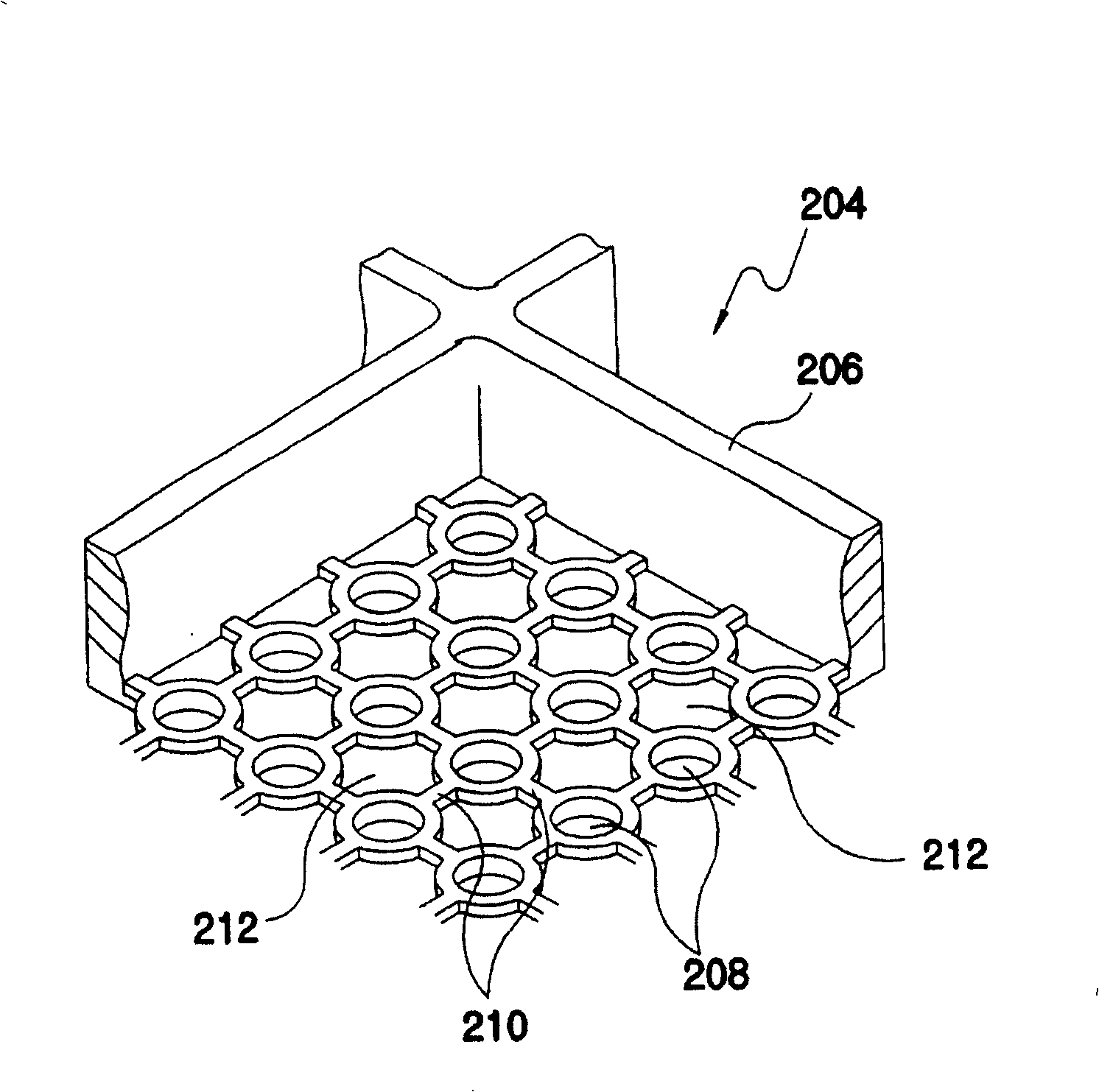

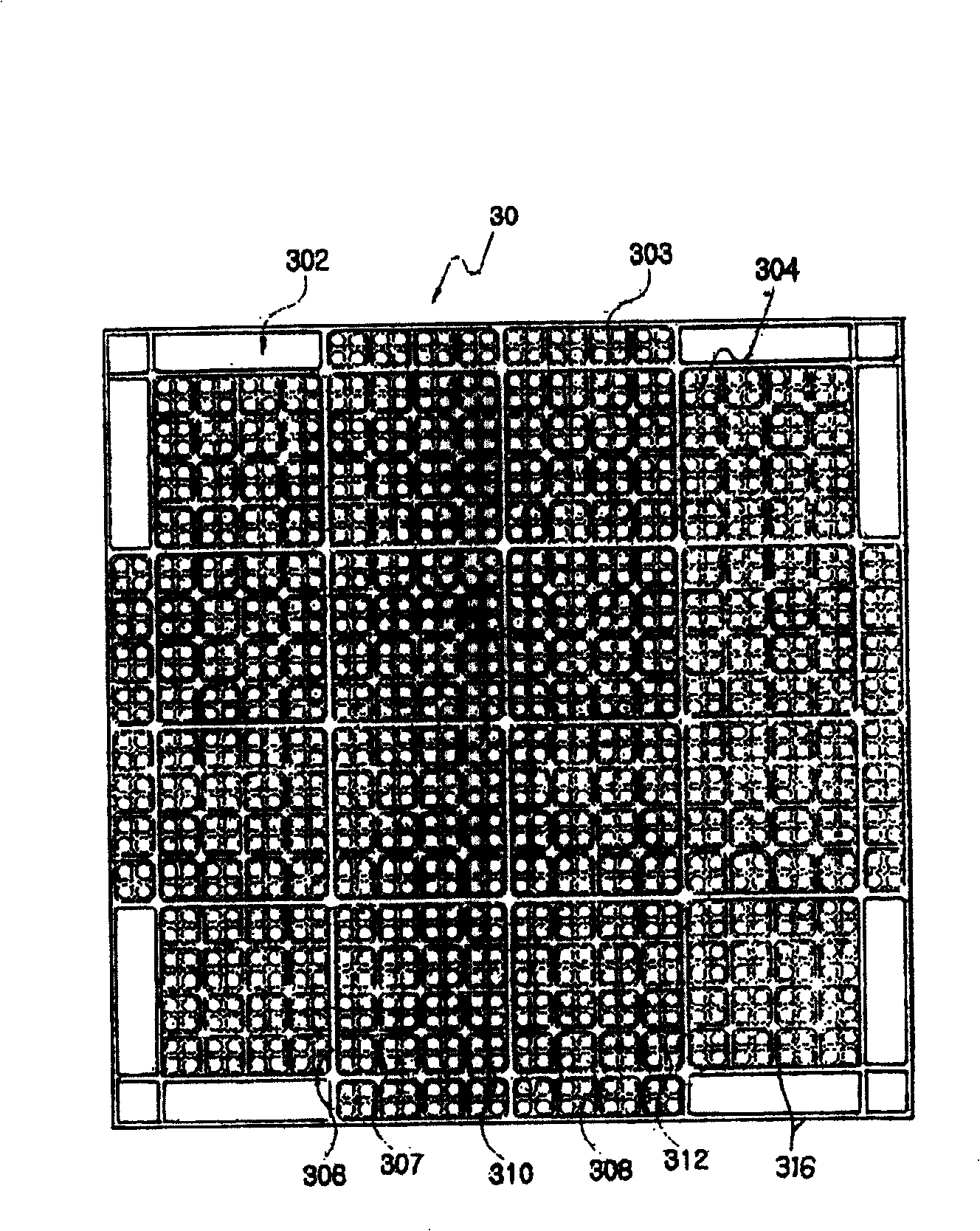

[0037] image 3 It is a plan view which shows the state which turned over the floor panel which is preferable in this invention. Figure 4 will be image 3 An enlarged perspective view of an enlarged representation of a portion of the panel, Figure 5 yes Figure 4 Top view of the panel shown. Figure 6 is a cross-sectional view of a floor panel of a preferred embodiment of the present invention, Figure 7 will be image 3 A top view of an enlarged representation of a portion of the panel, Figure 8 is along Figure 7 The line A-A is taken from the cutaway view.

[0038] As shown in these drawings, in the floor panel 30 of the preferred embodiment of the present invention, the edge rib 316 constituting the panel edge portion 302 has been reinforced in thickness compared with the existing panel, and it has a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com