Ablation-free self-adaptive heat-resistant and damping system for high supersonic aerocraft

A hypersonic, aircraft technology, applied in aircraft, aerospace aircraft, aircraft parts, etc., can solve the problems of complex aerodynamic structure on the surface of the aircraft, increase the weight of the aircraft, etc., and achieve the effect of reducing shock wave resistance and reducing surface temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

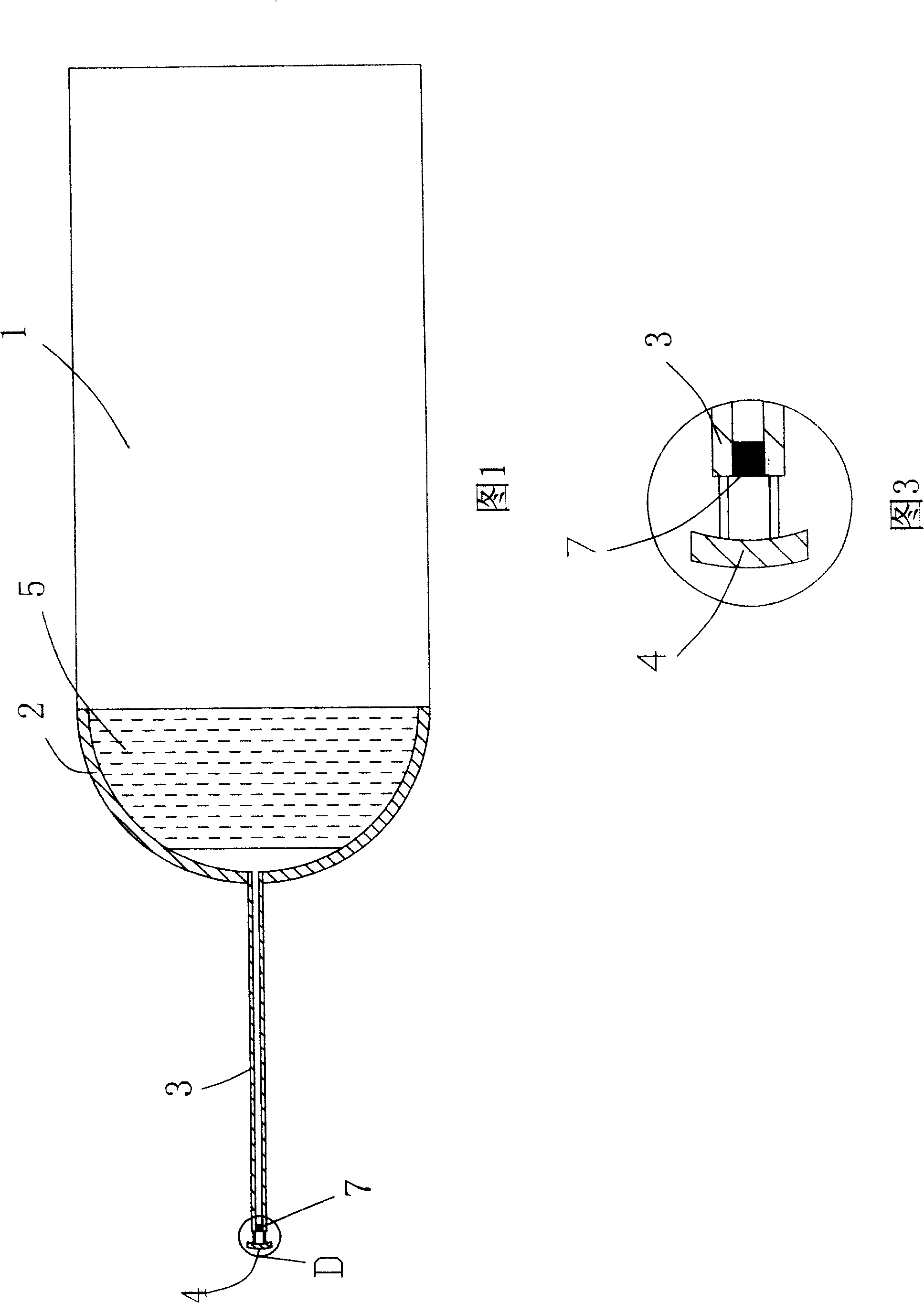

[0015] As shown in Figure 1, the present invention is to arrange a heat-resistant and good heat transfer pressure vessel 2 at the front end of the aircraft 1. The vessel 2 can be designed as a hemispherical shape suitable for gas flow, or it can be other suitable shapes such as a hemispheroid. The shape, as long as it satisfies the fluidity of the gas is relatively good. A certain amount of heated and evaporated liquid 5 is filled in the container 2, and a strut 3 and a strut top baffle 4 are arranged on the end face of the container 2 away from the aircraft 1 .

[0016] When flying at hypersonic speed, a head cone shock wave 8 will be formed around the aircraft 1, as shown in FIG. 2 . The high-temperature gas after the shock wave 8 will heat the pressure vessel 2 at the head of the aircraft, and the liquid 5 will absorb the heat of the container wall and evaporate, and will be ejected from the top of the strut 3, and cool the baffle plate 4 at the top of the strut, maintainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com