Oil ship

A technology of oil tanker and oil bag, which is applied to the tanker. It can solve problems such as low economic benefits, increased opportunities for crude oil to enter the sea, and marine environmental pollution, so as to achieve the effects of increasing economic benefits, improving operating rates, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

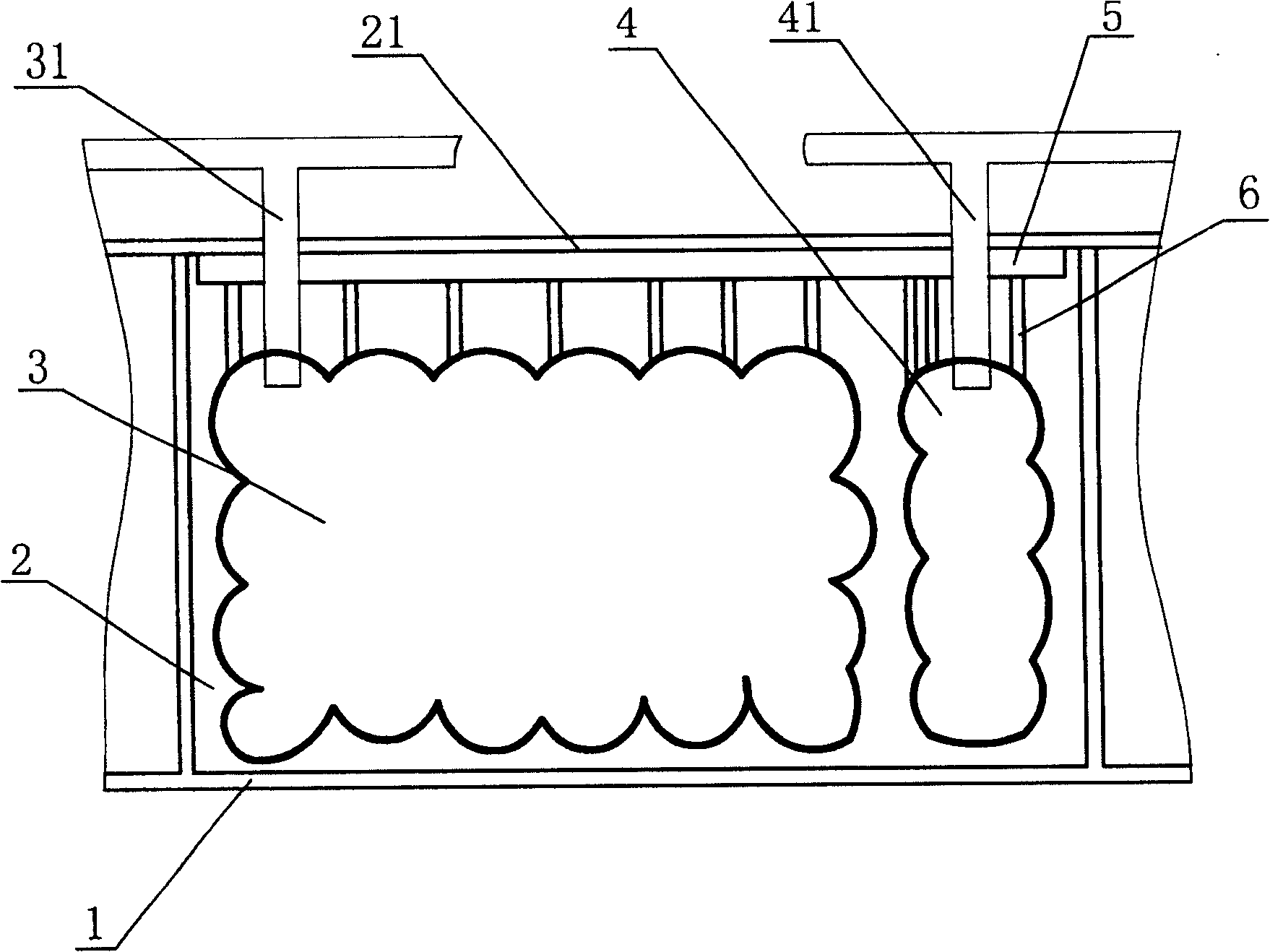

[0011] Embodiment 1: As shown in the figure, an oil tanker includes a double-layer hull 1 and a cargo oil tank 2. An oil bag 3 and a water bag 4 are arranged in the cargo oil tank 2, and an oil pipe 31 is arranged on the oil bag 3. The bladder 4 is provided with a water pipe 41, the bulkhead 21 of the cargo oil tank 2 is provided with a slide rail 5, and a plurality of pulley assemblies 6 are arranged on the slide rail 5, and the lower ends of the pulley assemblies 6 are respectively fixed to the oil bladder 3 and the water bladder 4 connected, so as to realize the free contraction and alternate use of the oil bag 3 and the water bag 4, the wall of the oil bag 3 is provided with an electric heating device (not shown in the figure), and the outside of the oil bag 3 is provided with a steel wire mesh (Fig. not shown), the temperature resistance of the oil bladder 3 is greater than or equal to 80°C, and the pressure resistance is greater than or equal to 10 atmospheres. In additio...

Embodiment 2

[0012] Embodiment two: the tanker is a single-layer hull, and one to two double water bladders used as fresh water and seawater are used in all water bladders, so that when the tanker unloads oil and fills water or needs ballast between unloading and loading oil, Seawater can be loaded into the dual-purpose water bladder to be used as a ballast tank, and when arriving at an oil loading place or a water loading place, seawater can be released, or fresh water can be loaded, or space can be made for the oil bladder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com