Revolving switch valve

A switching valve, rotary technology, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve the problems that the sliding valve core cannot realize stable switching, and the intelligent electric head cannot realize intelligent switching, so as to improve the reliability of operation Performance and service life, convenient use and maintenance, and stable lubricating oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

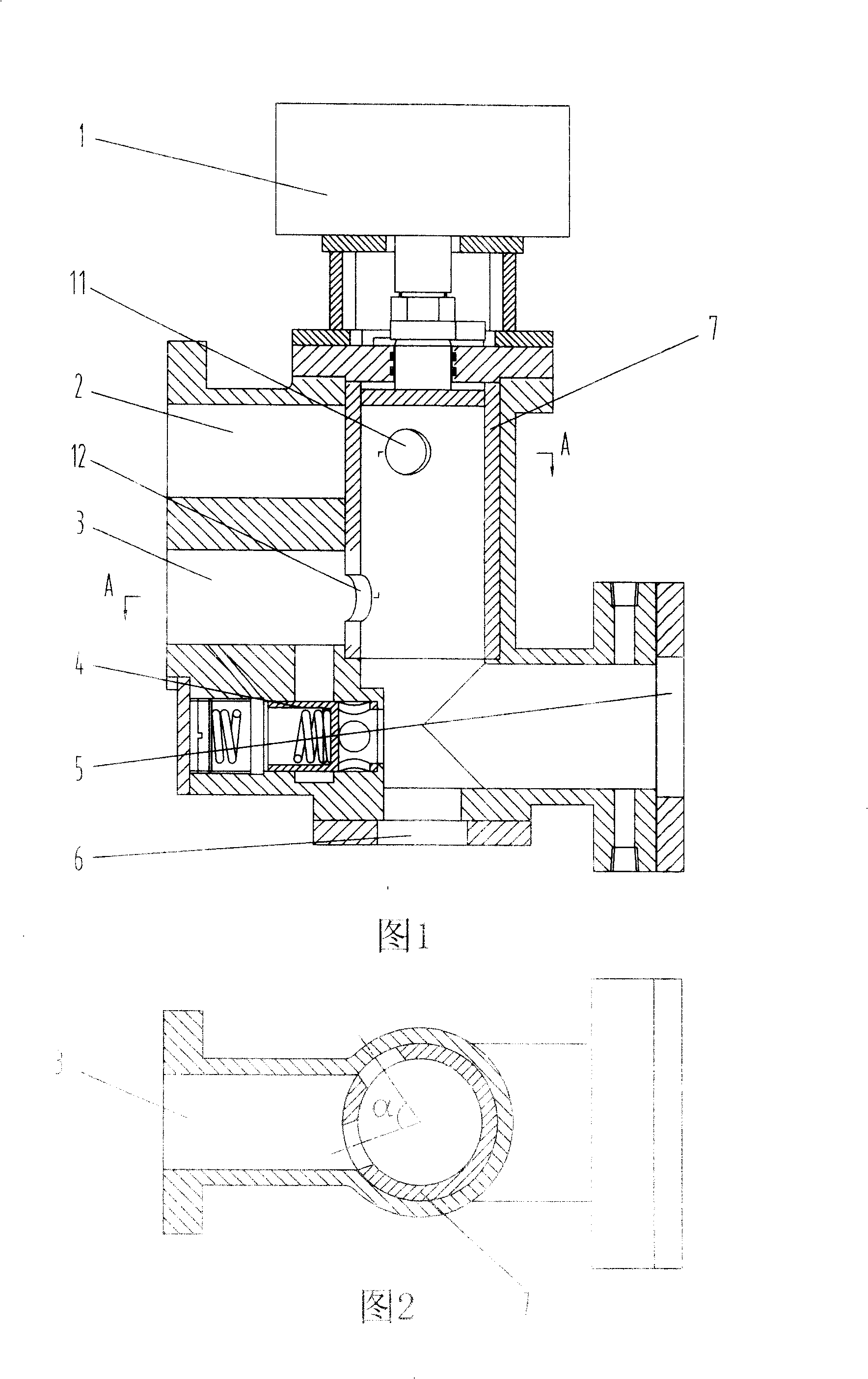

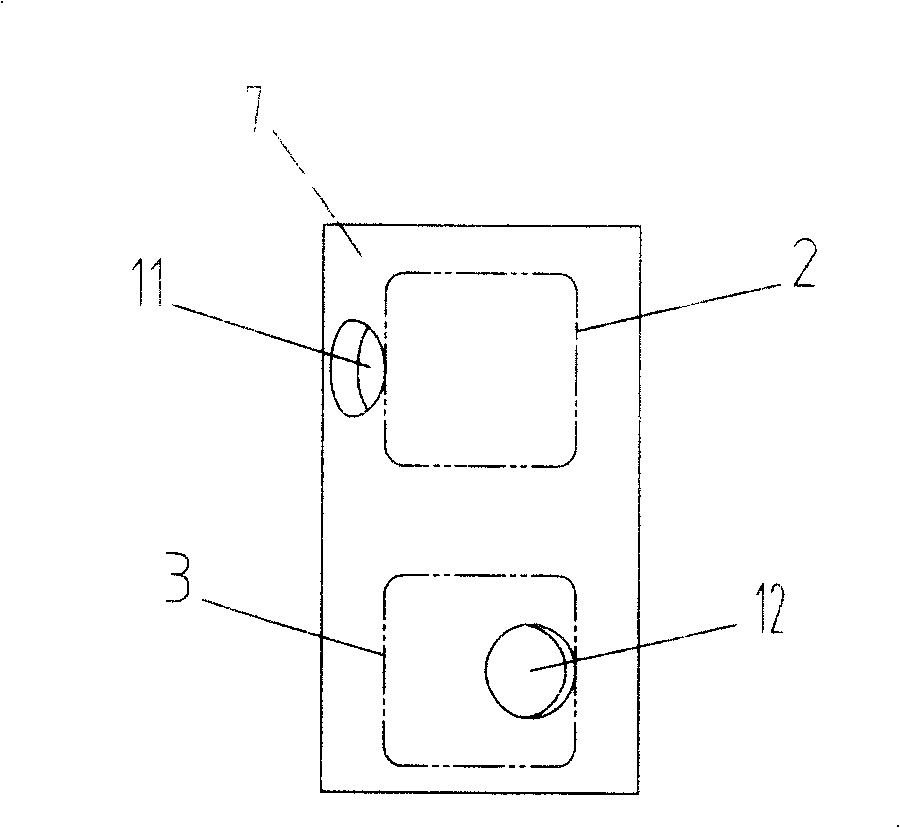

[0016] As shown in FIG. 1 , the rotary spool type intelligent electric switching valve of the present invention will be described with reference to FIG. 2 .

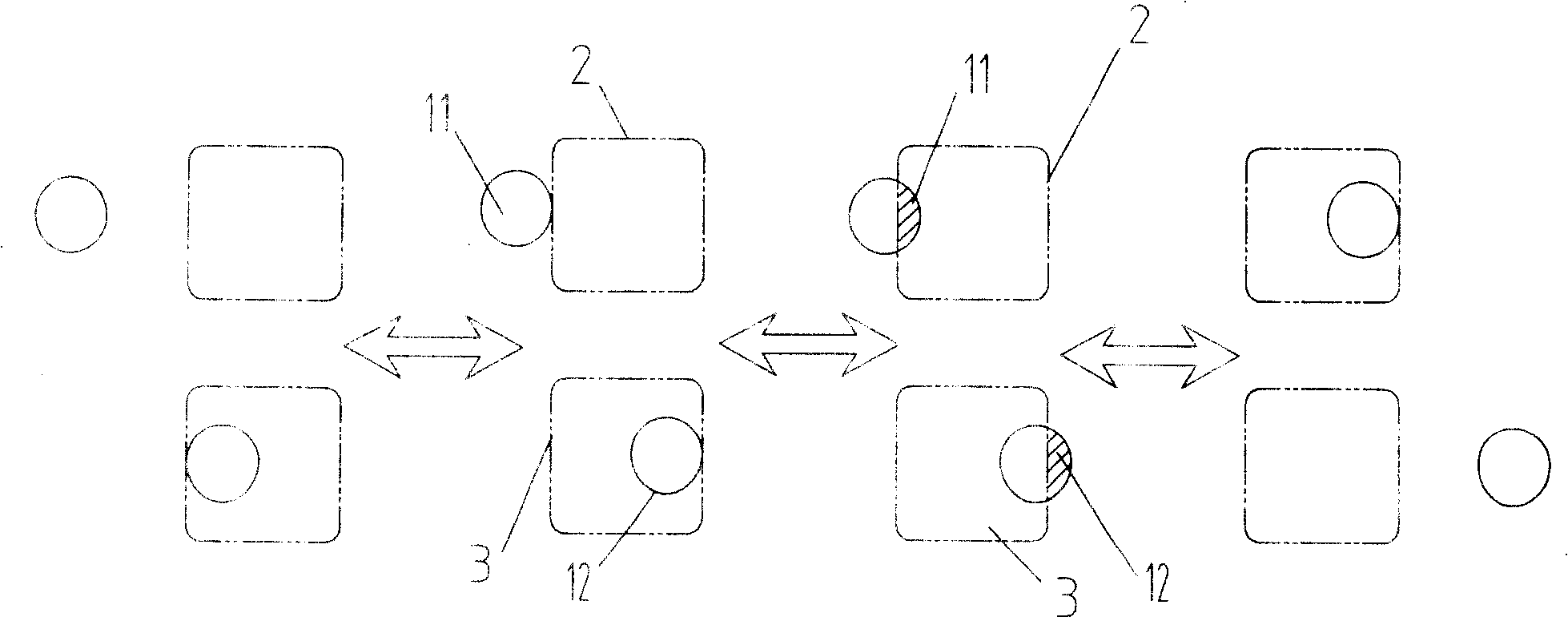

[0017] Wherein, the bottom of the cylindrical rotary valve core 7 communicates with the oil inlet hole 5 . An oil outlet hole 6 is opened on the passage where the inner cavity of the valve core 7 communicates with the oil inlet hole 5 . The cylinder body of the valve core 7 is provided with the same main oil hole 11 and oil drain hole 12 . A main working oil hole 2 is arranged on the valve body corresponding to the position of the main oil hole 11 on the outer side of the cylinder body of the valve core 7 . In use, the main working oil hole 2 is communicated with the main oil hole 11 by rotating the spool 7 to an appropriate position (such as image 3 and 4 Shown); On the valve body corresponding to the position of the drain hole 12 on the outside of the spool 7 cylinder, a working oil discharge hole 3 is arranged. In...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap