Fully automatic continuous extruding and continuous coating machine utilizing front-hinged locking shoe system

A fully automatic and cladding machine technology, applied in metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problems of large lock shoe force, high pressure, and low proportion of common parts, and achieve lock shoe Long arm, easy operation, lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

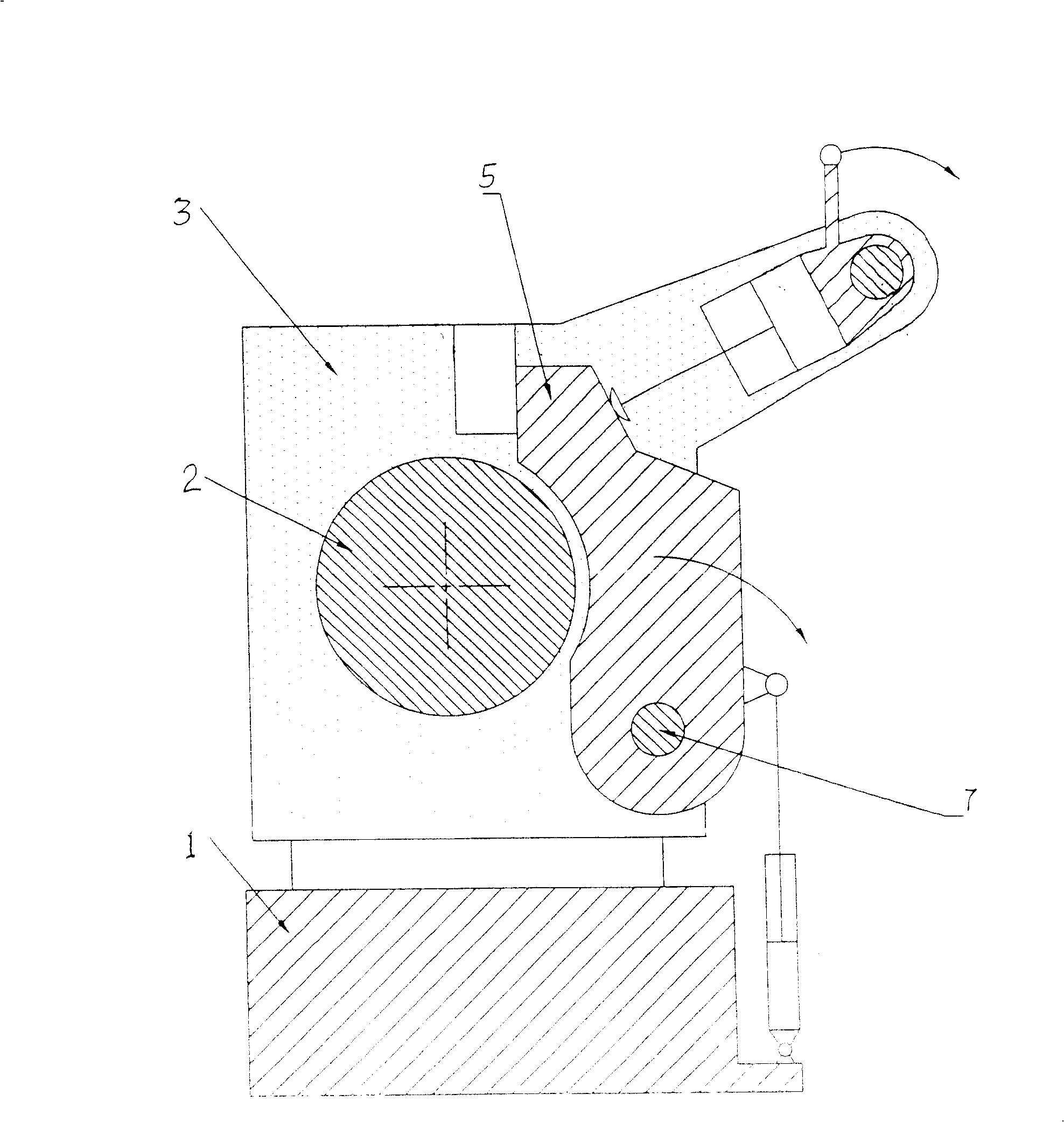

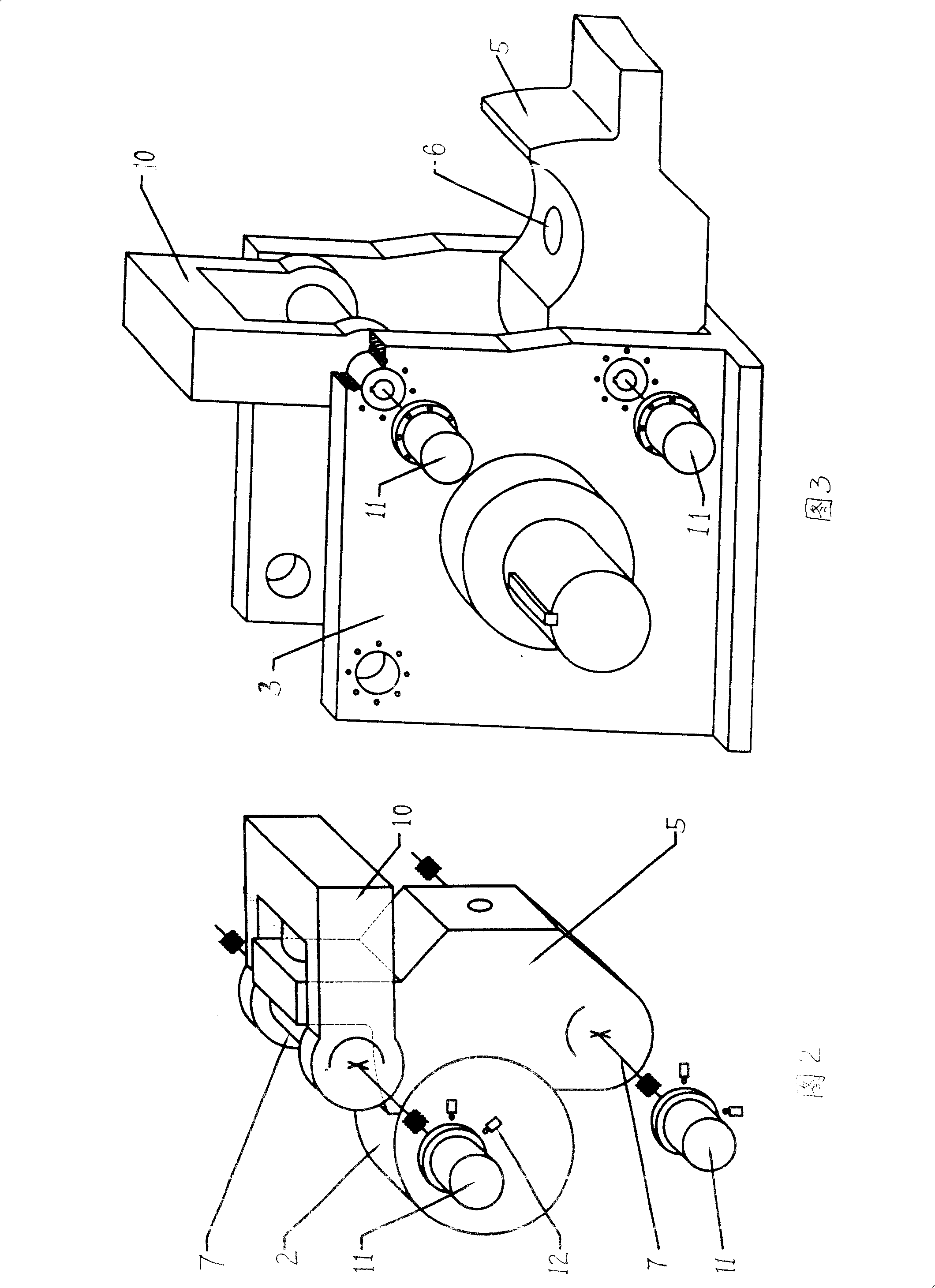

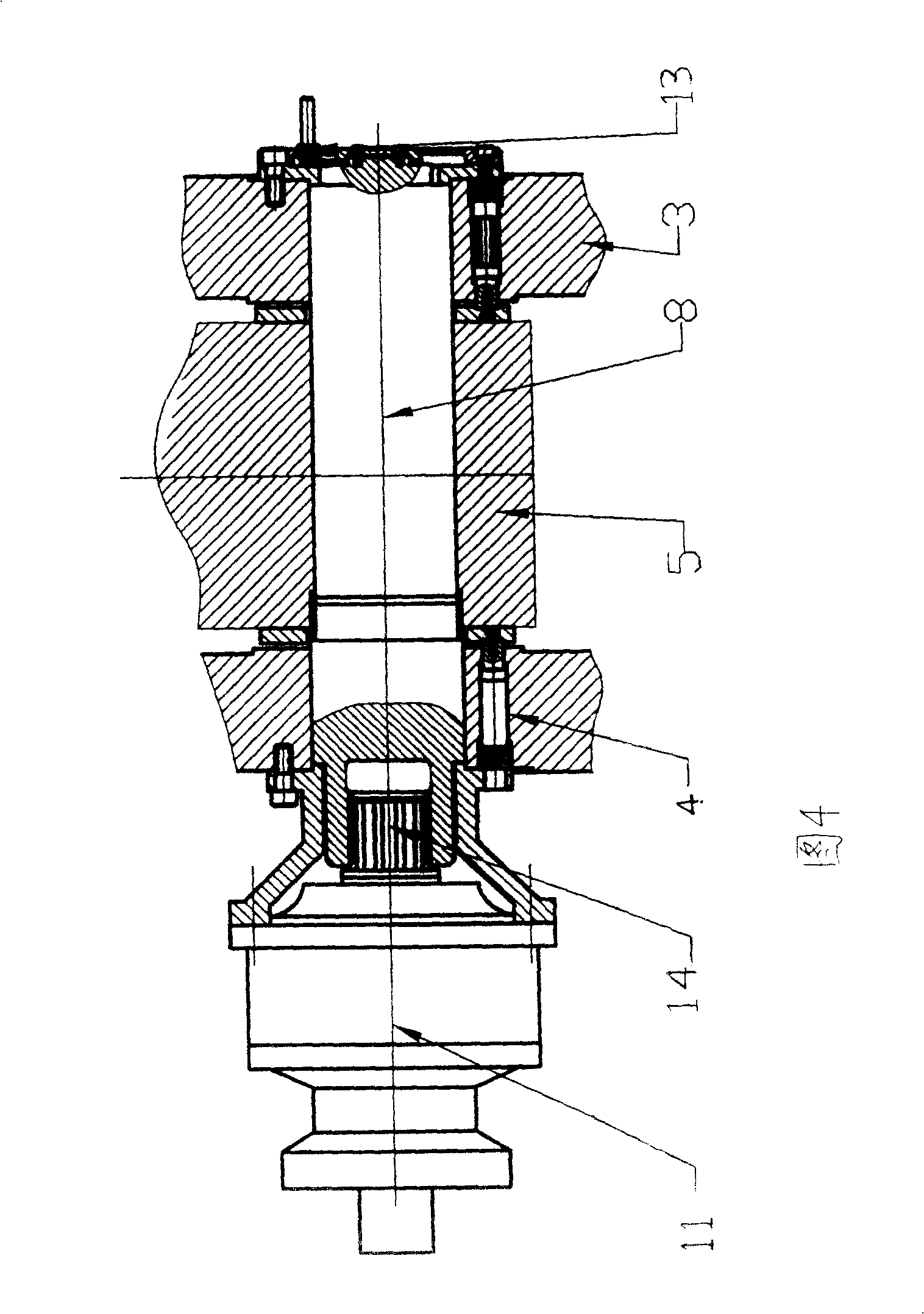

[0023] As shown in Figure 2-4, a fully automatic continuous extrusion and continuous coating machine using the front hinge lock shoe system, the base 1 and the frame 3 are integrated, and the driving power part of the lock shoe swing arm and the shoe seat is in production On the side of the product outlet direction, the extrusion wheel 2 is installed on the bearing of the frame 3, and rotates with a fixed axis under the drive of power. The shoe seat 5 and the lock shoe swing arm 10 are respectively connected with the hinge shaft 7 through keys, and the two ends of the hinge shaft are installed in the positioning holes of the frame 3 to form sliding bearings, and one end of the hinge shaft is connected with the output shaft of the driver 11 through a key 14 , the other end is connected to the position indicator 13, and the position of the shoe seat or the lock shoe swing arm is detected by the proximity switch. The shoe seat 5 can move axially along the hinge axis, and is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com