Preparation method of gradient polymer optical fiber premade rod

A technology of optical fiber preform and polymer, which is applied in the direction of optical components, other household appliances, household appliances, etc., can solve the problems of unsatisfactory optical fiber bandwidth performance, inability to accurately control the distribution curve of the refractive index in the radial direction of optical fiber, etc., and achieve good bandwidth performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

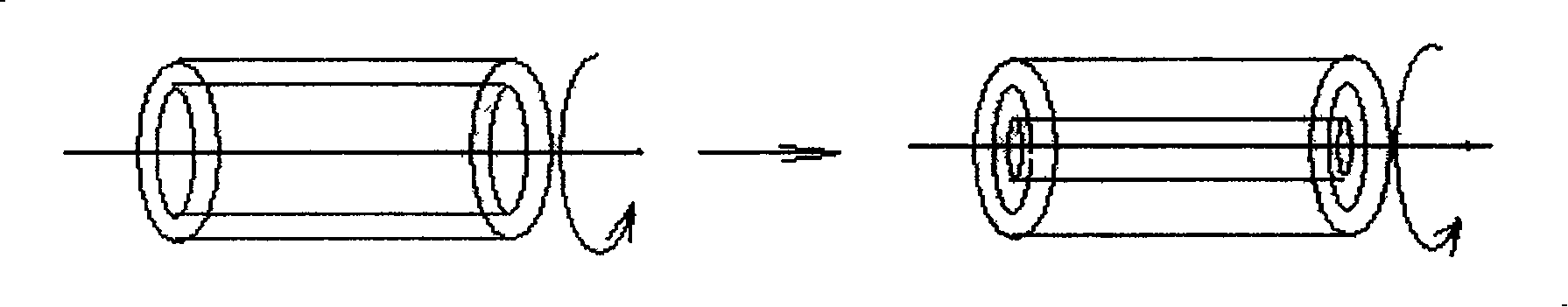

Method used

Image

Examples

Embodiment 1

[0025] First add 1.8g of high-purity azobisisobutyronitrile (AIBN), 2ml of dodecanethiol to 600g of high-purity MMA monomer, stir at 85°C, prepolymerize to a conversion rate of 15%, cool down, stop stirring, and add to In a stainless steel tube with a polished inner wall and one end closed, the tube has a diameter of 32 mm and a length of 1000 mm. Pass high-purity nitrogen gas through the tube to exclude oxygen in the system, and seal it. Fix the stainless steel tube on the centrifuge device, turn on the centrifuge at a speed of 1000rpm, set the temperature at 45°C, and centrifuge for 6 hours, so that the added MMA adheres to the inner wall of the stainless steel tube and polymerizes to form a PMMA layer with a thickness of about 6mm.

[0026] In the second step, add 1.2g of high-purity azobisisobutyronitrile (AIBN), 1ml of dodecanethiol, and 14ml of bromobenzene to 300g of high-purity MMA monomer, stir at 85°C, and prepolymerize until the conversion rate is 15%. , cool down,...

Embodiment 2

[0029] First, add 2.4g of high-purity azobisisobutyronitrile (AIBN), 2ml of dodecanethiol to 600g of high-purity MMA monomer, stir at 85°C, prepolymerize to a conversion rate of 15%, cool down, stop stirring, and add to In a stainless steel tube with a polished inner wall and one end closed, the tube has a diameter of 32 mm and a length of 1000 mm. Pass high-purity nitrogen gas through the tube to exclude oxygen in the system, and seal it. Fix the stainless steel tube on the centrifuge device, turn on the centrifuge at a speed of 1000rpm, set the temperature at 50°C, and centrifuge for 3 hours, so that the added MMA adheres to the inner wall of the stainless steel tube and polymerizes to form a PMMA layer with a thickness of about 6mm.

[0030]In the second step, add 1.5g of high-purity azobisisobutyronitrile (AIBN), 1ml of dodecanethiol, and 14ml of bromobenzene to 300g of high-purity MMA monomer, stir at 85°C, and prepolymerize until the conversion rate is 15%. , cool down,...

Embodiment 3

[0033] First add 1.8g of high-purity azobisisobutyronitrile (AIBN), 2ml of dodecanethiol to 600g of high-purity MMA monomer, stir at 85°C, prepolymerize to a conversion rate of 15%, cool down, stop stirring, and add to In a stainless steel tube with a polished inner wall and one end closed, the tube has a diameter of 32 mm and a length of 1000 mm. Pass high-purity nitrogen gas through the tube to exclude oxygen in the system, and seal it. Fix the stainless steel tube on the centrifuge device, turn on the centrifuge at a speed of 1000rpm, set the temperature at 45°C, and centrifuge for 6 hours, so that the added MMA adheres to the inner wall of the stainless steel tube and polymerizes to form a PMMA layer with a thickness of about 6mm.

[0034] In the second step, add 1.2g of high-purity azobisisobutyronitrile (AIBN), 1ml of dodecanethiol, and 21ml of bromobenzene to 300g of high-purity MMA monomer, stir at 85°C, and prepolymerize to a conversion rate of 15%. , cool down, stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com