Fuel injection device for internal combustion engine

A technology of fuel injection device and fuel injection valve, which is applied to fuel injection device, fuel injection pump, internal combustion piston engine, etc., can solve the problems of low accuracy of test learning value and inability to completely reduce the change of instrument error characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

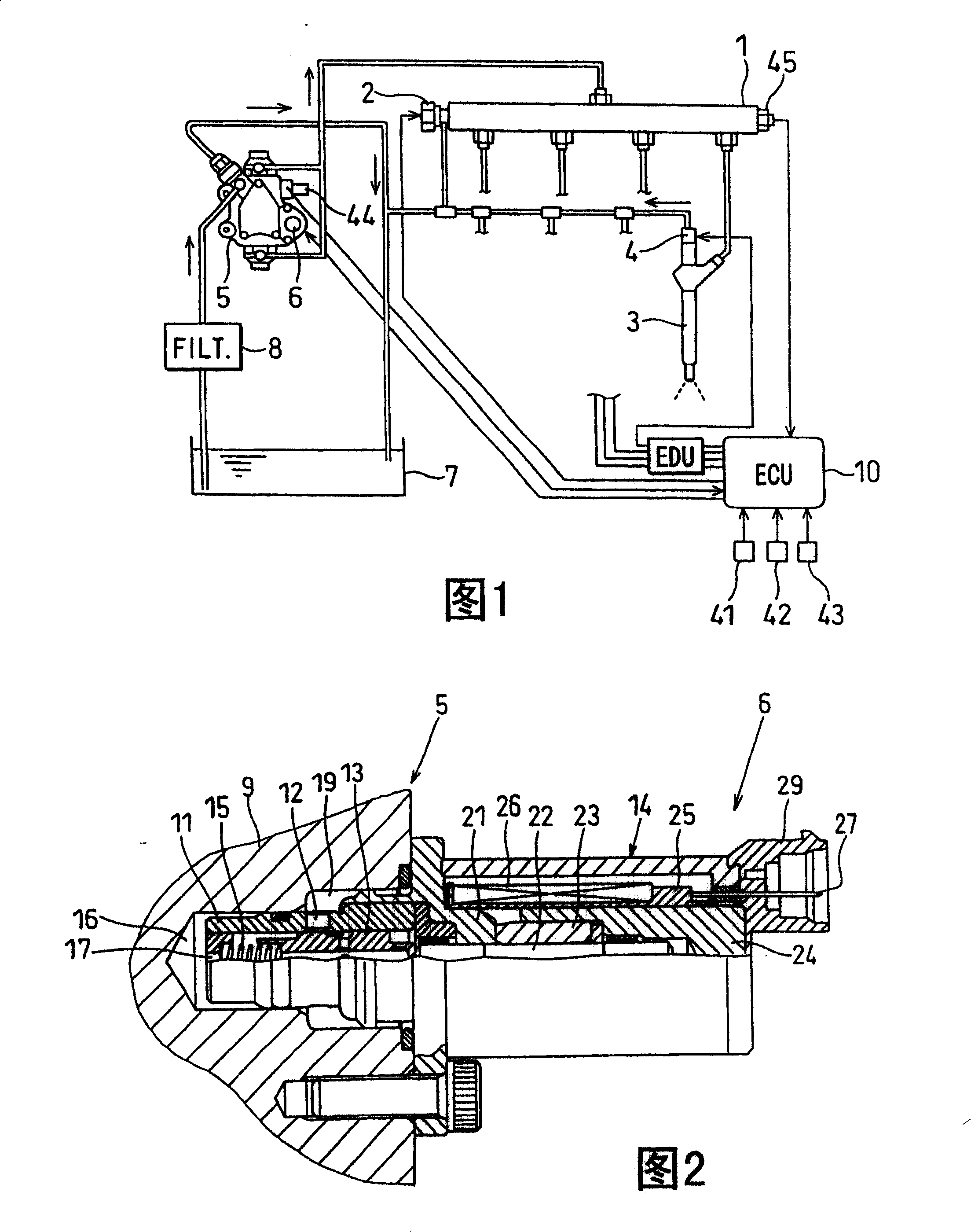

[0018] Referring to FIG. 1 , there is shown a common rail fuel injection system according to an exemplary embodiment of the present invention. The internal combustion engine control system according to this embodiment has an exhaust emission purification device (not shown), a turbocharger (not shown), a common rail fuel injection system (pressure accumulation fuel injection device), and an internal combustion engine control unit (internal combustion engine controller, ECU) 10. The exhaust emission purification device purifies exhaust emissions flowing out of combustion chambers of individual cylinders of an internal combustion engine, such as a diesel engine (multi-cylinder diesel engine), installed in a vehicle, such as an automobile. A turbocharger uses the exhaust energy emitted by the exhaust gases to supercharge the intake air drawn into the combustion chambers of the cylinders of the internal combustion engine. The common rail fuel injection system injects and delivers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com