Glass moulding-shaping device capable of simplifying mounting-dismounting programme

A glass and program technology, applied in glass forming, glass manufacturing equipment, glass pressing, etc., can solve the problems of complex disassembly and assembly procedures of molds, fine-tuning the thickness of glass lens 6 centers, and poor demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The aforementioned and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of the two preferred embodiments with reference to the drawings.

[0018] Before presenting a detailed description, it is noted that in the following description, similar elements are denoted by the same reference numerals.

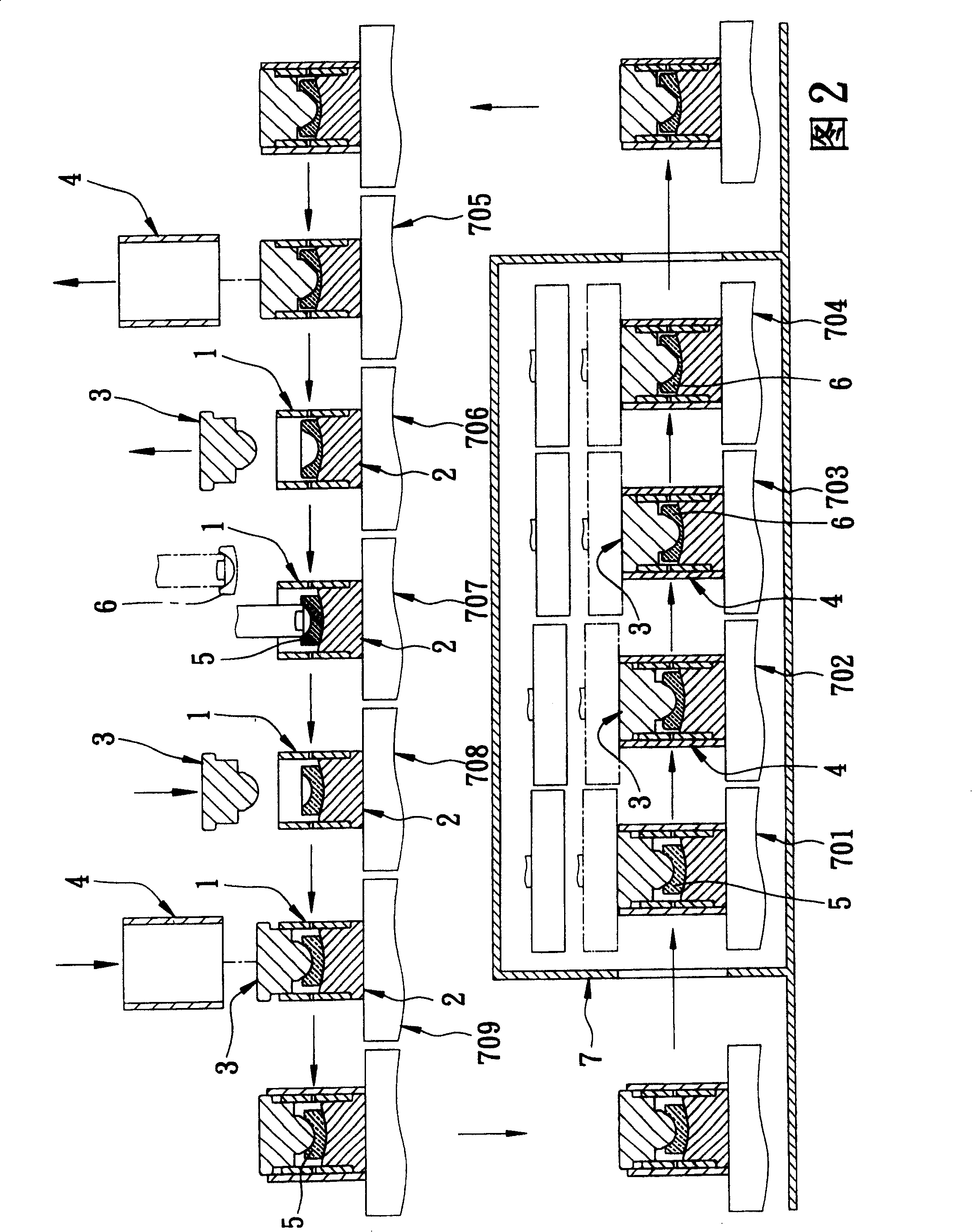

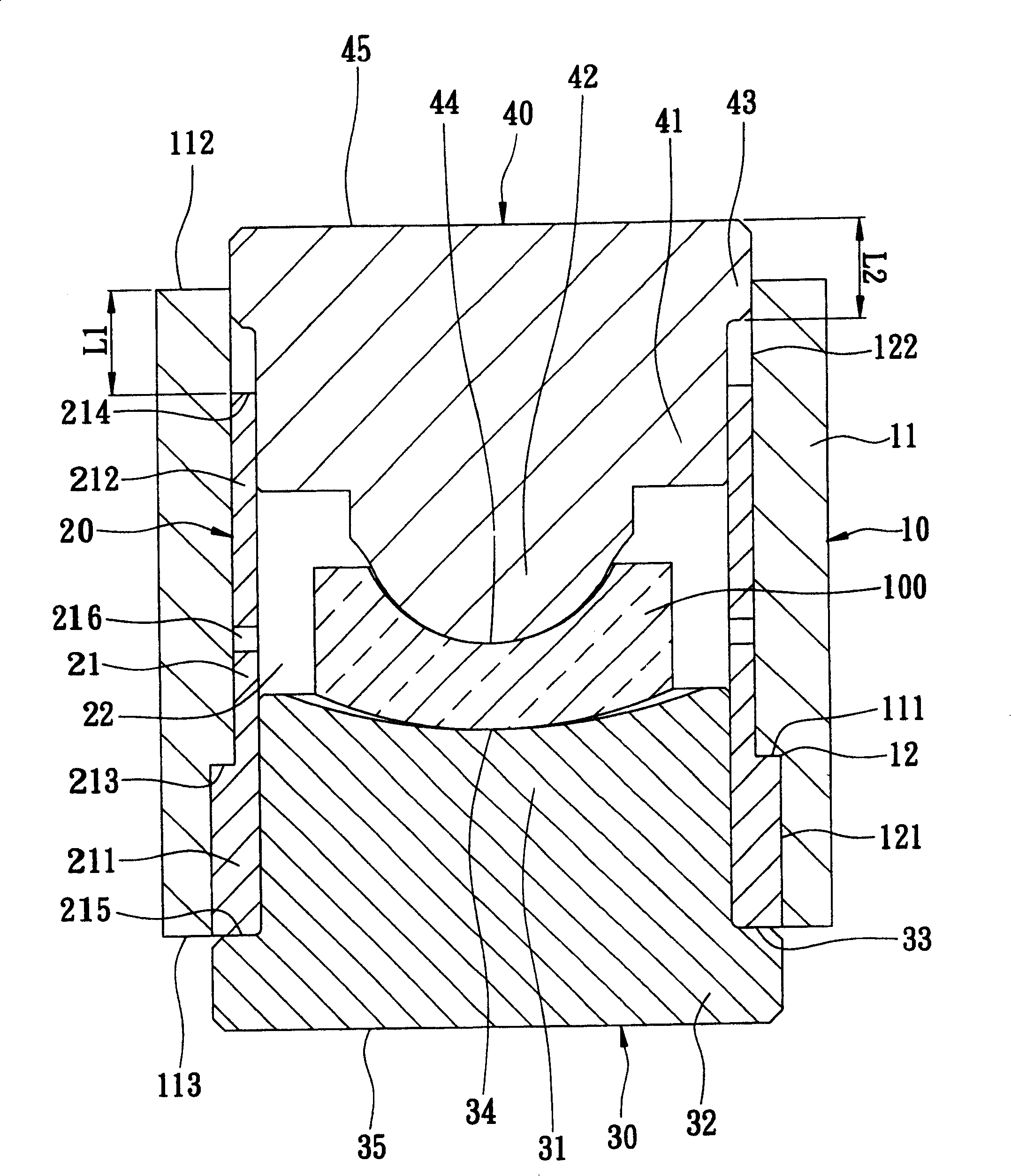

[0019] refer to image 3 , the first preferred embodiment of the glass molding device that can simplify the disassembly procedure of the present invention can be used to form a glass nitrate material 100 with a coefficient of thermal expansion α into a glass lens 200 (see Figures 4 and 5), the The glass molding device includes: an outer sleeve 10 , an inner sleeve 20 , a lower mold core 30 , and an upper mold core 40 .

[0020] The outer sleeve 10 has a first peripheral wall 11 , a first inner hole 12 surrounded and defined by the first peripheral wall 11 , and a first thermal expansion coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com