Method for improving self-lubrication of large-scale bearing by macromolecular material

A technology of polymer materials and sliding bearings, applied in the field of mechanical bearings, can solve the problems such as the application of PEEK materials that have not been officially reported, and achieve the effect of ensuring self-lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

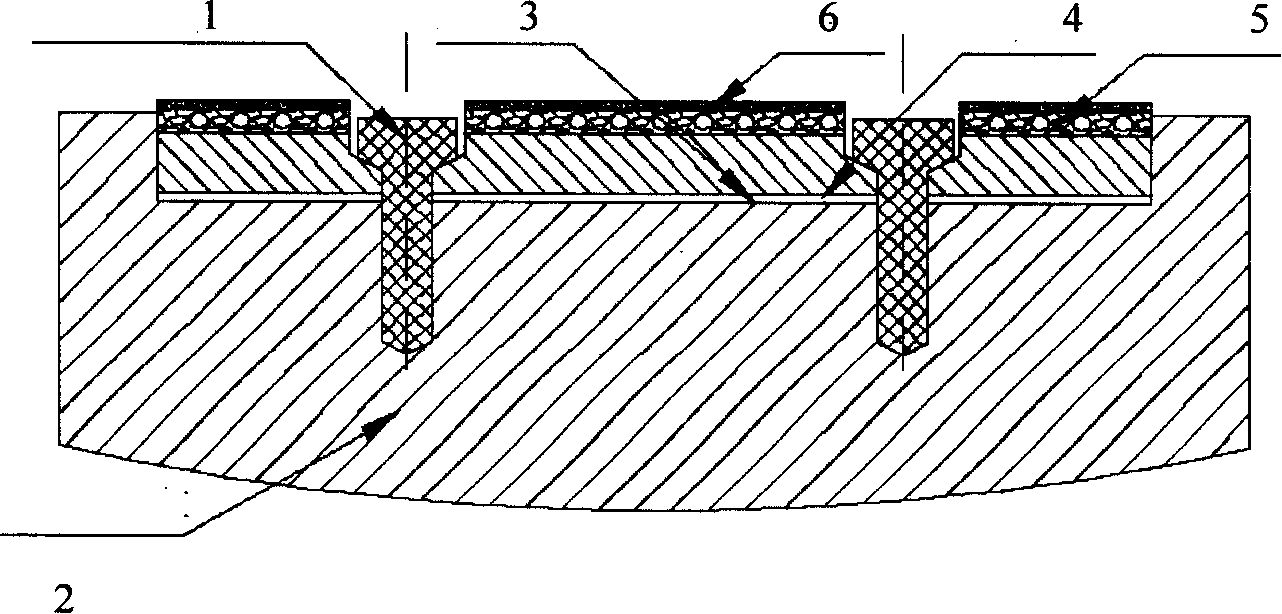

Image

Examples

Embodiment

[0014] Before the PEEK material 6 is assembled, perform a performance test on the PEEK material 6 . In the present invention, the PEEK material 6 is assembled on the bearing bush 2 with an inner diameter of 35 mm (two identical sets are made), and one set of the experimental bearing bush 2 equipped with the PEEK material 6 is immersed in oil. According to the load conditions in the application of PEEK material 6 large-scale sliding bearings, the load of PEEK material 6 performance test is determined to be 5MP load and the line speed is 2.1m / s, and the test is stopped after 120 hours of continuous operation; , The wear amount and friction coefficient of PEEK material 6 were sampled and recorded, and the oil-immersed lubrication experiment of PEEK material 6 was completed. Another set of experimental bearing bush 2 equipped with PEEK material 6 was soaked in oil at one time, and the dry friction test was also carried out under the conditions of 5MP load and line speed of 2.1m / s,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com