Jet dyeing machine and method for dyeing fabric rope

A technology for dyeing machines and fabrics, applied in the field of jet dyeing machines, can solve problems such as conflicts, reduce tension effects, reduce friction effects, and improve dyeing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

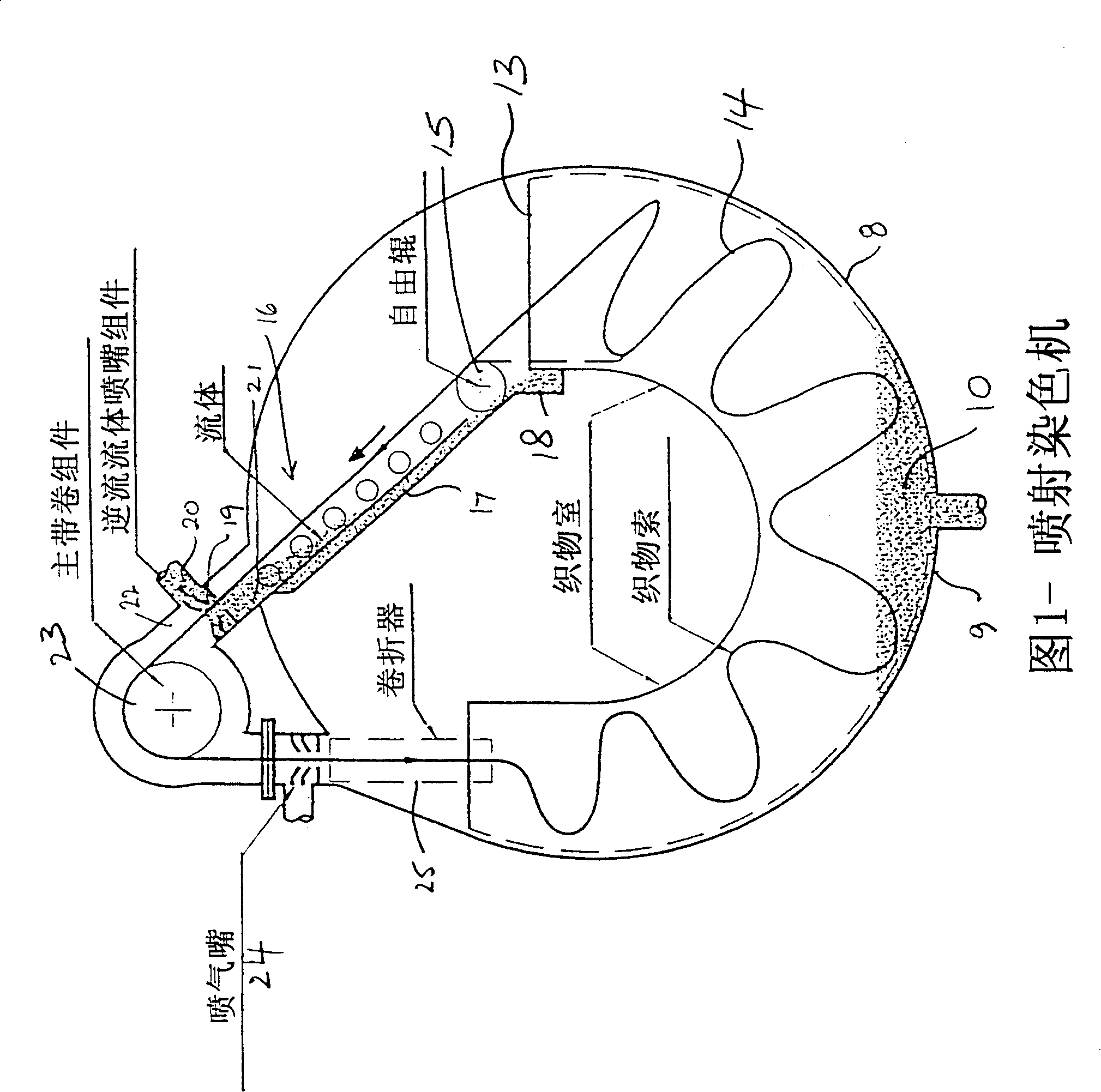

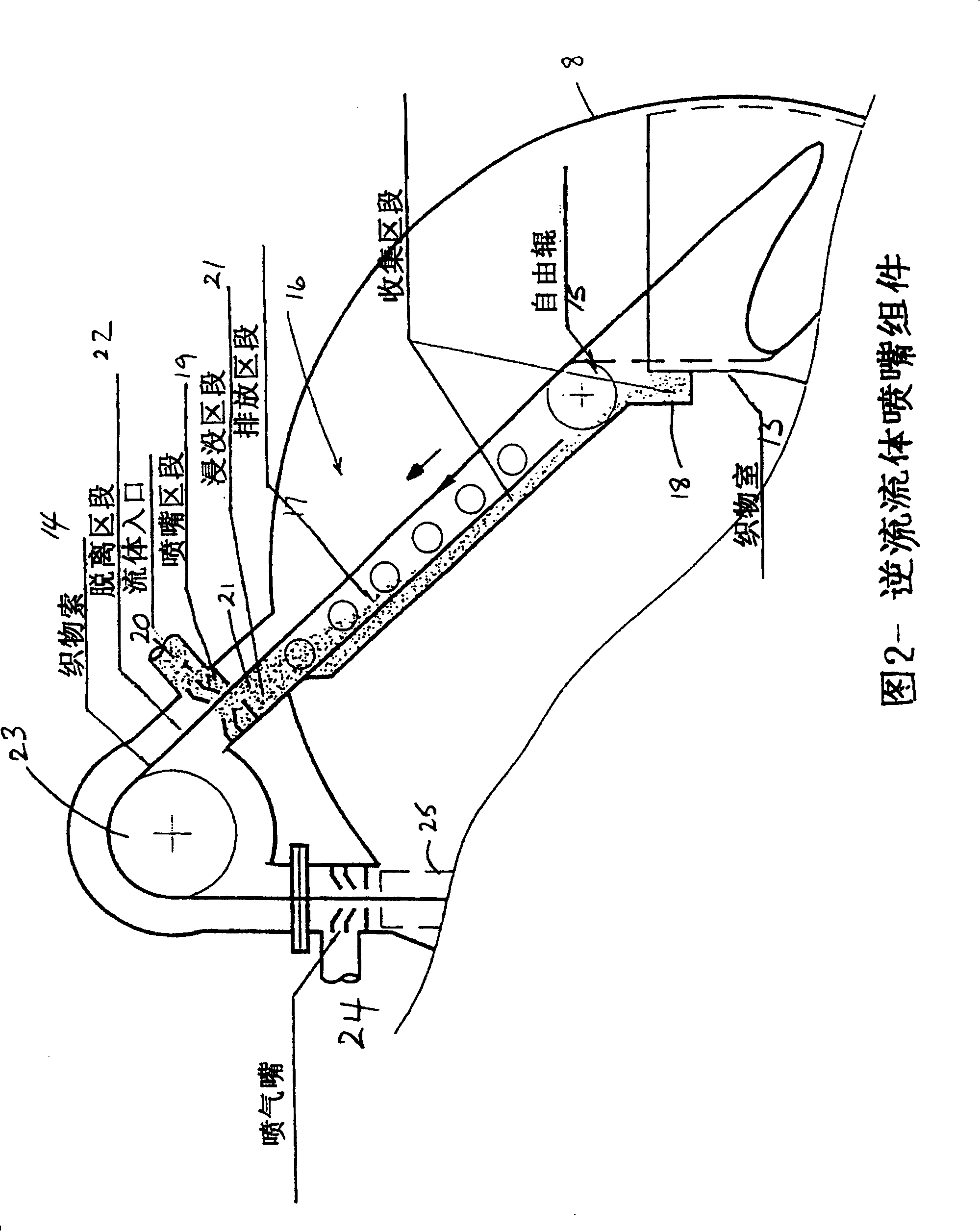

[0032] The jet dyeing machine comprises a dyeing vat 8, at the bottom 9 of which a reservoir for collecting the dye liquor 10 is provided, and a fabric chamber 13 located above the bottom 9 of the dyeing vat 8, a strip of which is folded The fabric rope 14 is guided through this chamber, and the dyeing machine also includes a free roller 15 positioned at the rear of the dyeing machine just above the fabric chamber, from which the fabric rope 14 is drawn.

[0033] The jet dyeing machine also includes a counterflow fluid nozzle assembly 16 through which the fabric cord 14 is directed. The counterflow fluid nozzle assembly 16 includes a lower discharge section 17 that slopes toward the horizontal and extends toward the free roll 15 , and includes a collection channel 18 below the free roll 15 .

[0034]The counterflow fluid nozzle assembly 16 also includes a fluid nozzle 19 for applying dye liquor to the fabric rope 14 . The nozzle 19 comprises an inlet 20 through which the dye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com