Apparatus for enlarging tube used in heat exchanger

A technology of heat exchanger tubes and heat exchangers, which is applied in the direction of heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of increased manufacturing costs and deteriorated transmission efficiency, and achieves increased productivity, improved transmission efficiency, and prevention of The effect of rail bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to explain the present invention in more detail, reference is made to the accompanying drawings.

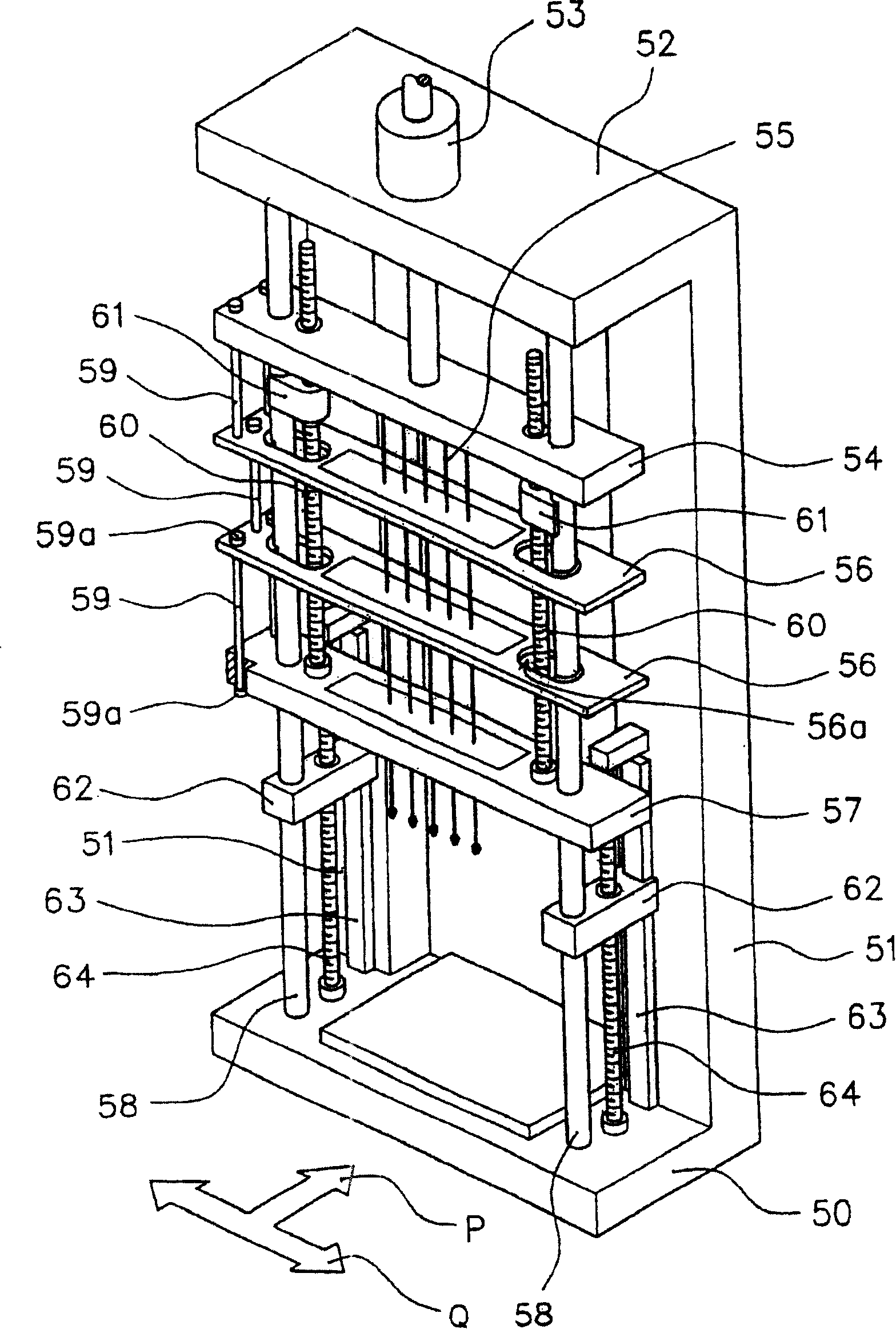

[0036] figure 1 Indicates the overall structure of the expanding device. The top 4 is erected across the upper ends of a pair of pillars 3 standing upward from the rear left and right positions of the base part 2 , and the device frame 1 is constituted by the base part 2 , the pillars 3 and the top 4 .

[0037] Further, a cylinder 5 having a cylinder rod 5 a that expands and contracts from the back of the top 4 toward the base 2 is attached to the top 4 .

[0038] The front end of the above-mentioned cylinder rod 5a is fixedly connected to the central part of the rectangular operating plate 6, and the operating plate 6 can be freely raised and lowered by the expansion and contraction of the cylinder rod 5a of the working cylinder 5.

[0039] In addition, a plurality of mandrels 7 for pipe expansion are vertically provided below the operation plate 6 , and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com