Structural member for mounting thermal insulation decorative material onto wall and method of use thereof

A technology for structural components and decorative materials, applied in building components, walls, building structures, etc., can solve problems such as block rupture, thermal insulation board and exterior veneer weight, hidden engineering risks, and inappropriate installation of expansion bolts. To achieve the effect of easy and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings.

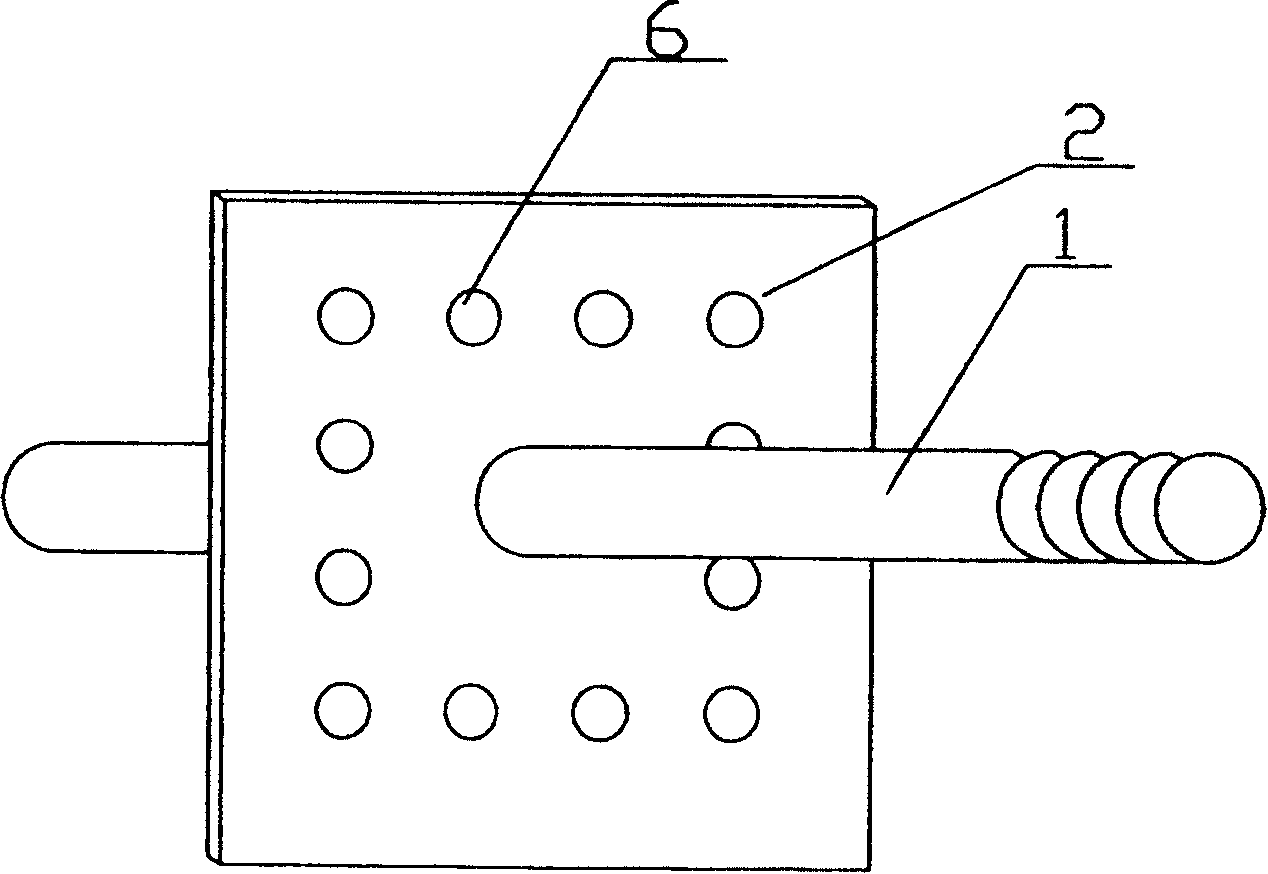

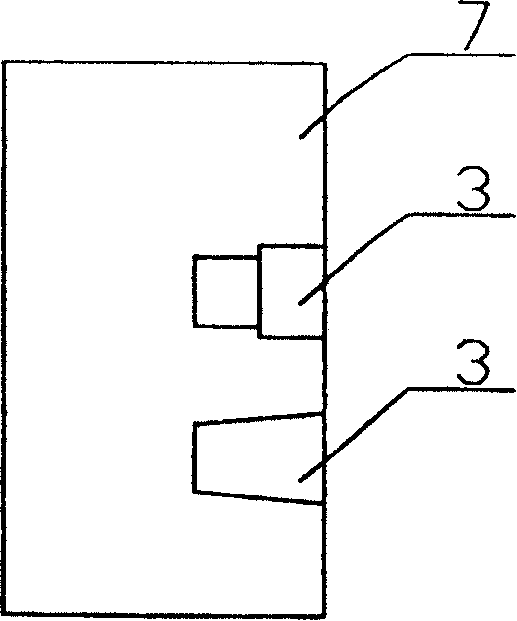

[0014] refer to figure 1 , figure 2 , The viscose iron sheet 2 is generally square or other polygons, and its area is generally about 100 square centimeters, and it can also be properly adjusted according to the difference in wall material strength. At about the center of the glued iron sheet 2, there is a nail-piercing hole 5, and the aperture of the hole is adapted to the diameter of the peg 1 passing through the hole. Around the nail piercing hole 5, several glue overflow holes 6 are distributed, and the aperture of this hole is about 5mm.

[0015] The tail end of the nail 1 is an external thread structure, which can cooperate with the fastening nut to adjust and fix the steel support net, and can also cooperate with the countersunk nut to directly connect with the nail groove on the back of the granite decorative board; It is processed into an internal thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com