Circular spray type spray nozzle

A nozzle and ring spraying technology, applied in the direction of spraying device, spraying device, etc., to achieve the effect of improving spraying force, improving uniformity, and convenient structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

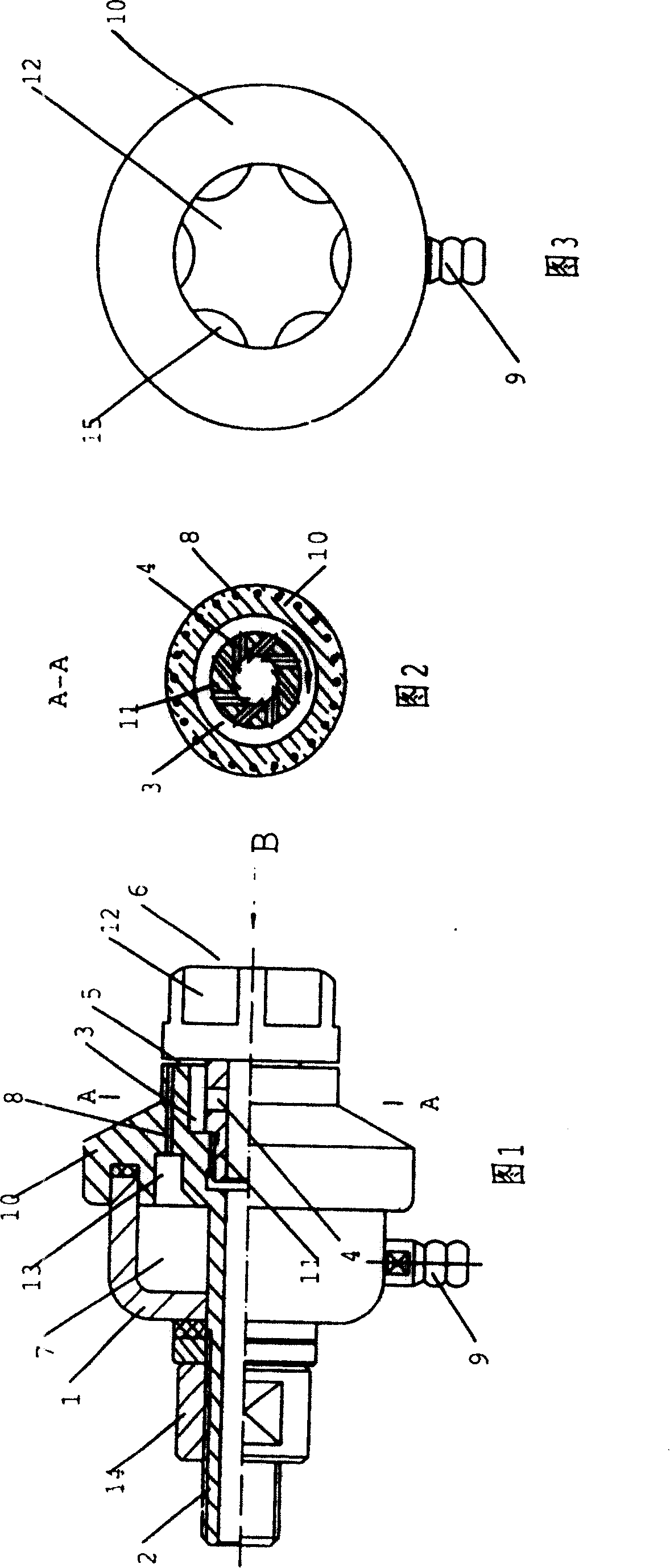

[0022] See attached picture. The annular nozzle 5 in the present invention is an annular gap located at the front end of the nozzle body, and the annular gap is perpendicular to the axis of the nozzle body, that is, perpendicular to the traveling direction of the gas. The liquid inlets 8 are distributed on the side wall of the annular gap forming the annular spout 5 . The pressurized gas travels straight forward in the nozzle body to the annular nozzle 5. When it suddenly turns 90° and changes the line, it is sprayed out in a 360° direction around the nozzle. The local negative pressure during injection will suck the liquid in the liquid inlet 8 into the gas. Form a gas-liquid mixture and spray it out.

[0023] Still refer to the accompanying drawings. The nozzle body in the present invention can adopt the structural form in which the intake pipe 2 is arranged in the casing 1 and a vortex generator is arranged at the front end of the intake pipe 2 . The annular air chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com