Method for controlling slitter-scorer apparatus

A control method and technology for a scribing machine, which are applied to the following control fields of a slitting scribing machine, can solve the problems of affecting processing, low qualified rate of finished products, interference, etc., and achieve the effect of preventing the decrease of qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Using the preferred embodiment and referring to the drawings, the operation method of the slitting and marking machine related to the present invention will be described below. In the following embodiments, although the slitting and scribing device in which the slitting machine and the scribing machine are installed in series is described as an example, it can also be applied to a separate slitting machine or a scribing machine.

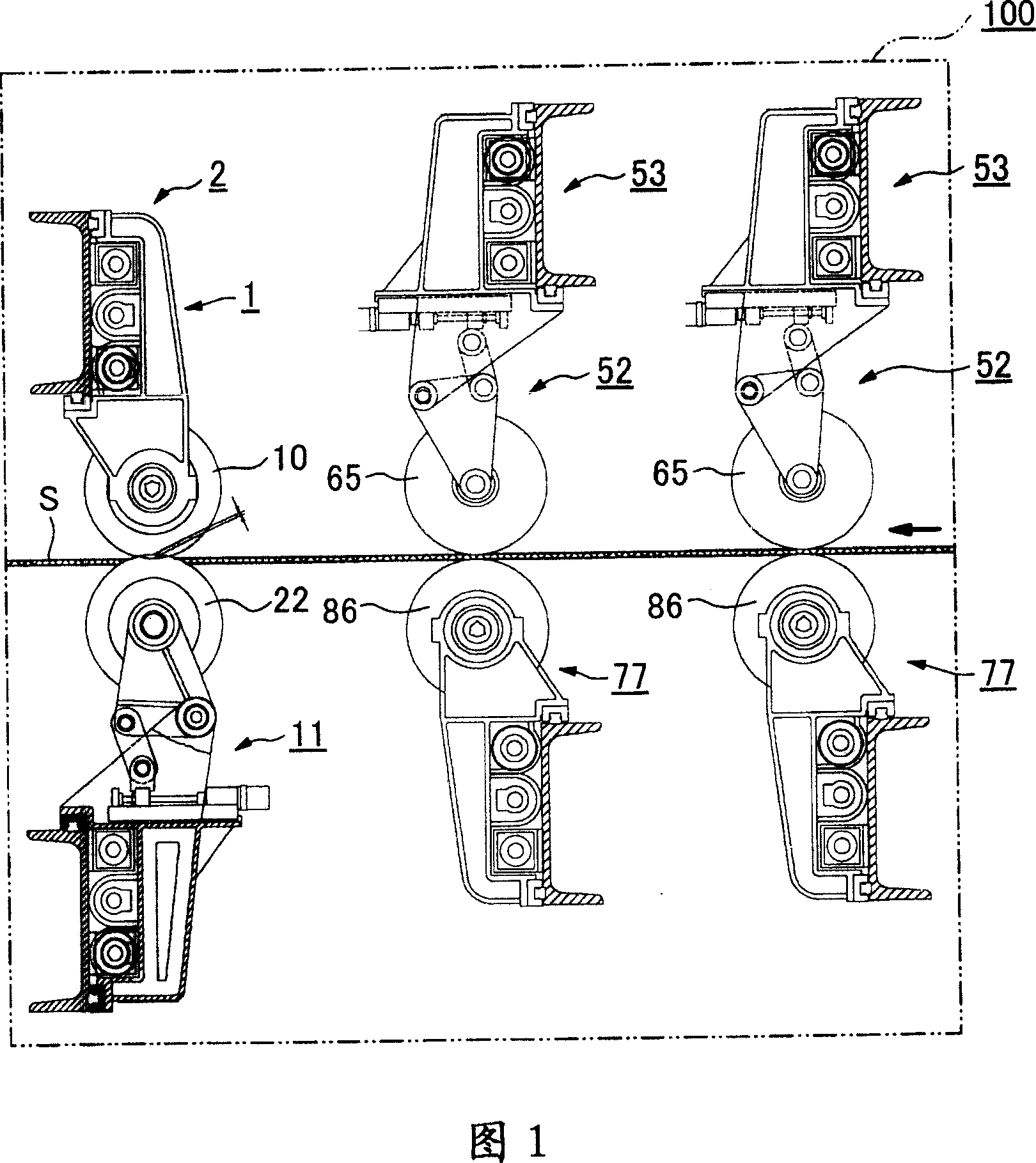

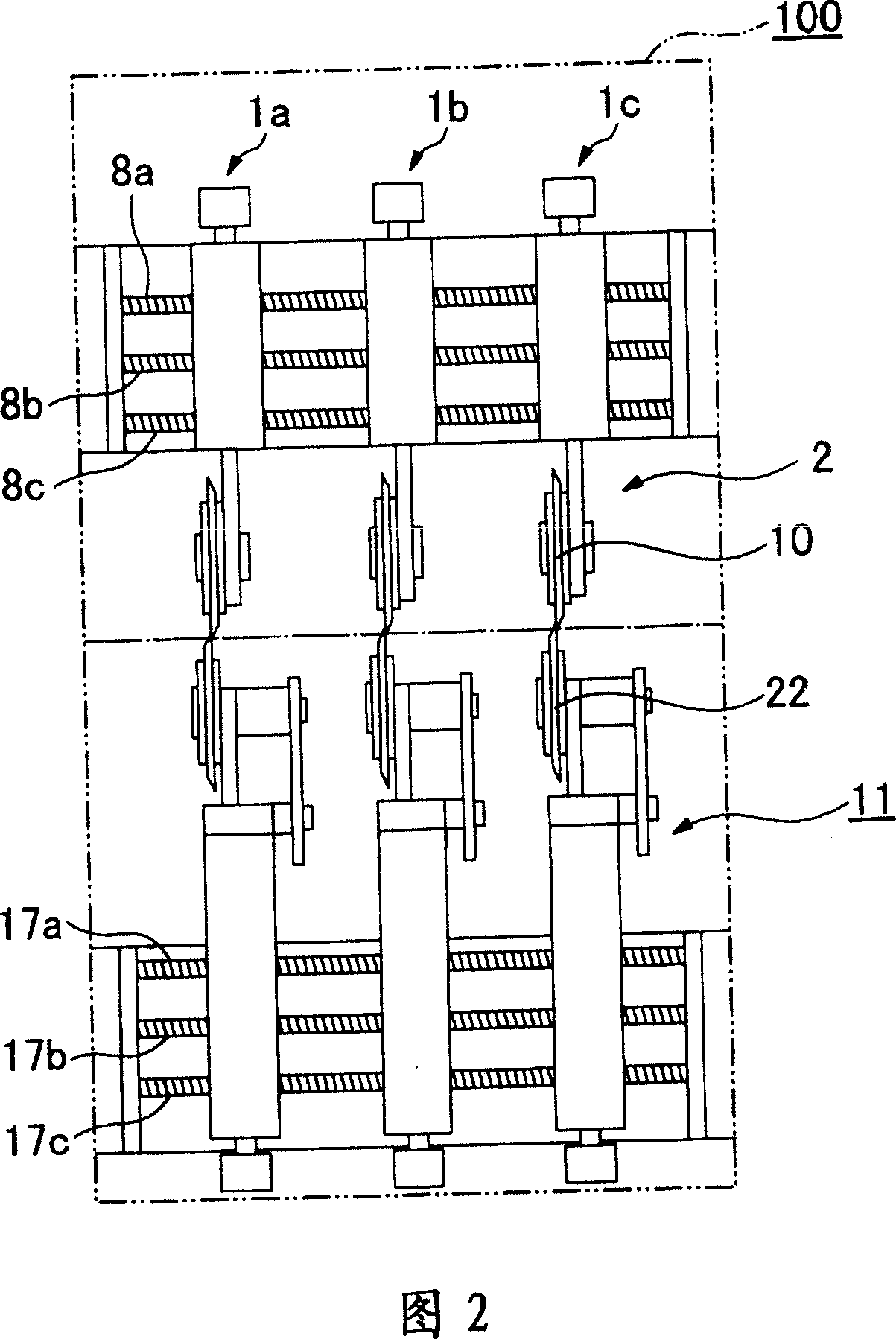

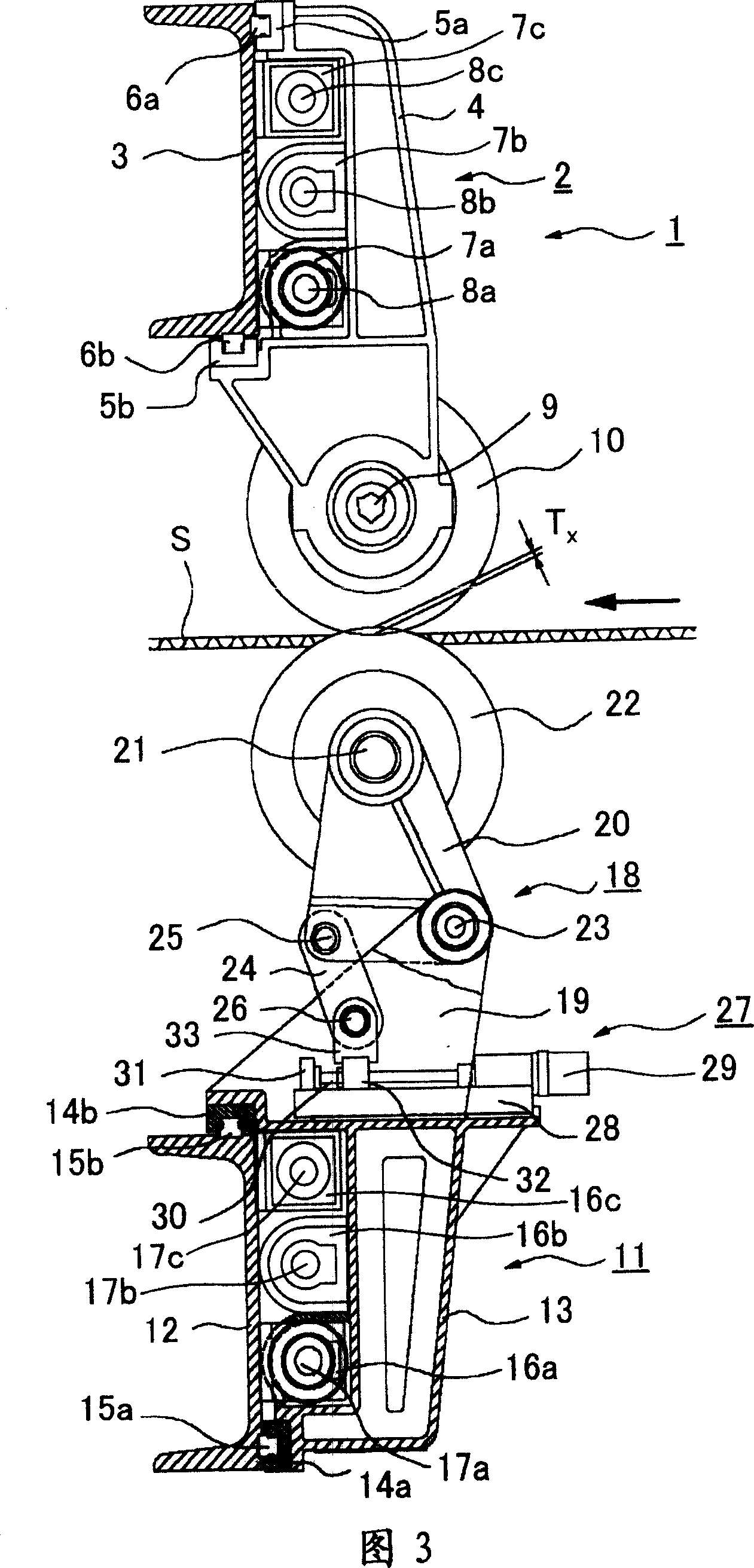

[0053] As shown in FIG. 1, the slitting and scribing device 100 is provided with two scribing machines 52 on the upstream side in the supply direction of the corrugated cardboard S, and one slitting machine 1 is provided on the downstream side. As shown in Fig. 2, the slitting machine 1 is provided with three slitting machines 1a, 1b, 1c along the width direction, that is, the direction substantially perpendicular to the cardboard feeding direction. Similarly, each scribing machine 52 has three scribing machines 52a, 52b, 52c in the width directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com