Flat clothing for refined jute tangle fiber

A fine yellowing and cover needle technology, which is applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problem of high bending stiffness of refined jute fibers, difficulty in ensuring clear cotton web and high quality yarn production Level, it is difficult to ensure that the flat card clothing can grasp, card and transfer fine jute fibers, so as to achieve the effect of no fiber entanglement and clear cotton web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

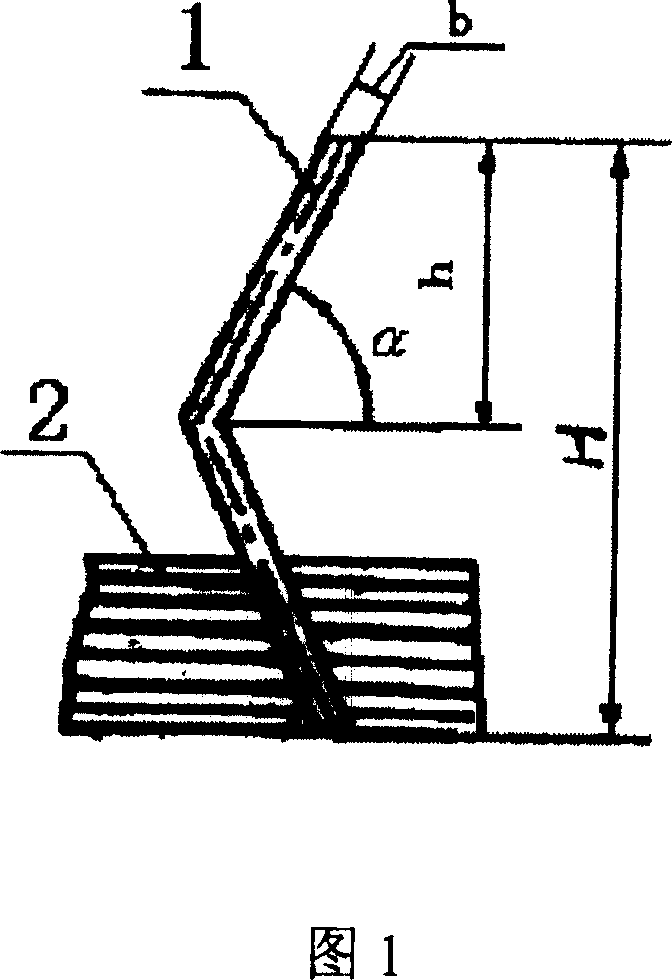

[0010] As shown in Fig. 1, a special flat card clothing for refined jute fiber comprises a bottom 2 and a carding needle 1 planted on the bottom 2, and is characterized in that the carding needle 1 adopts sparse dense needle planting, super large Working angle, ultra-short upper knee, ultra-fine combing needle configuration, the combing needle working angle α of the combing needle 1 planted on the bottom 2 is 80-82 degrees, the total height H of the combing needle is 6.8-7.0 mm, and the height of the upper knee is h 3.0 to 3.5 mm, the tip fineness b is 0.15 to 0.18 mm, the tip density is 250 to 350 needles per square inch, and the bottom 2 is a seven-layer rubber surface.

[0011] Because the present invention adopts sparse and dense pattern planting needles, super-sized working angle, ultra-short upper knee, and ultra-fine combing needles, it is very beneficial to the grasping, carding and timely transfer of refined jute fibers, and can ensure refined jute fibers The velvet f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com