Air suction connecting apparatus for closed rotary compressor

A rotary compressor and connecting device technology, applied in the field of compressor construction, can solve the problems of closed rotary compressors such as difficult operation, compression efficiency drop, thermal deformation, etc., to prevent pressure rise, improve performance, and reduce defects rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

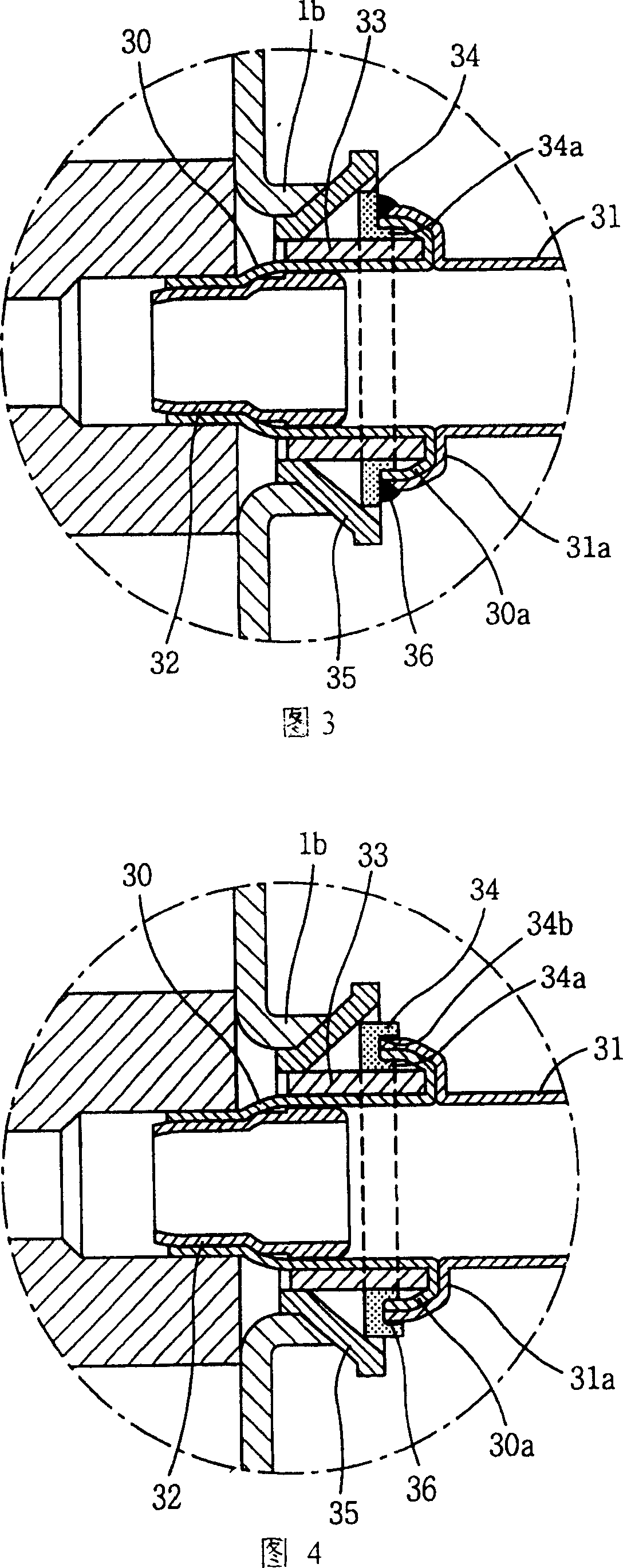

[0025] The present invention will be described in detail below with reference to the figures and examples.

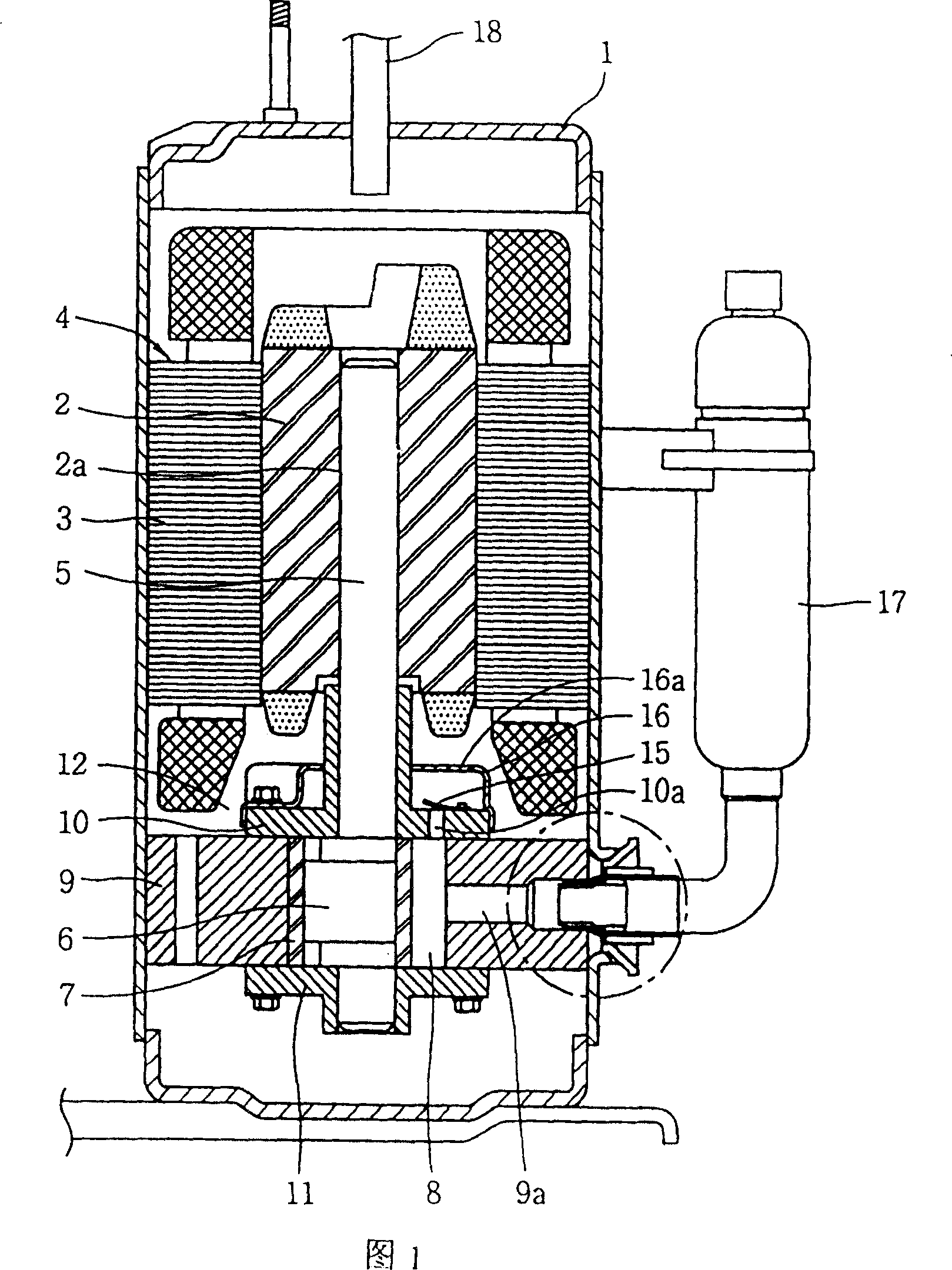

[0026] As shown in Figures 1 and 3, a motor 4 is installed inside the airtight container 1, and a crankshaft 5 is pressed and fixed in the center of the rotor 2, and a rolling piston 7 is inserted into the lower end and outside of the eccentric part 6 of the crankshaft 5 to form a cylinder. 9. A compression space 8 where the inner rolling piston 7 compresses the refrigerant gas, and a compression mechanism 12 composed of upper and lower bearings 10 and 11.

[0027] A gas-liquid separator 17 is provided on the side of the suction port 9a of the cylinder 9 to prevent the inflow of liquid refrigerant, and a discharge pipe 18 is provided on the top of the sealed container 1 to discharge the high-pressure refrigerant gas compressed by the compression mechanism 12 to the outside.

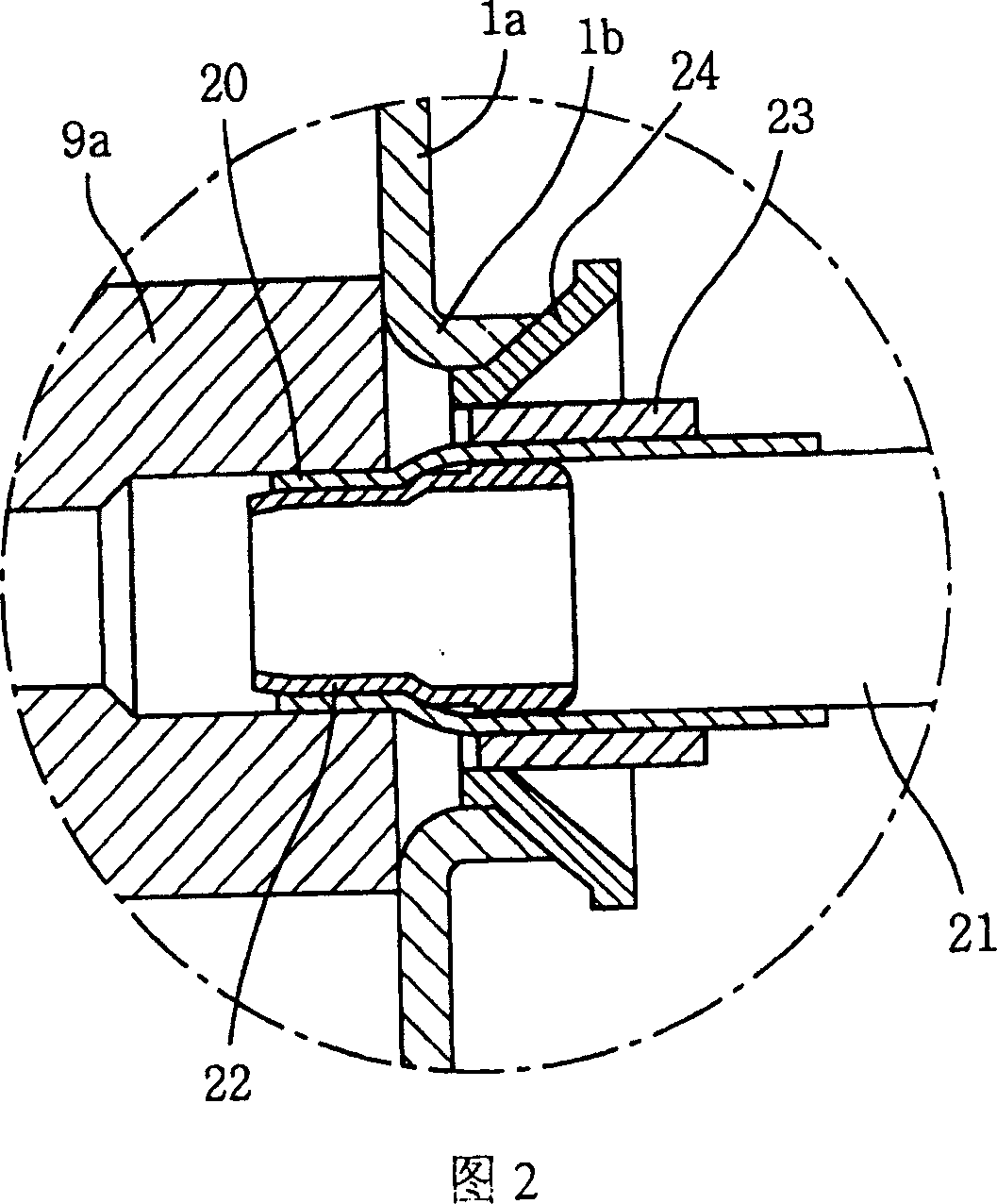

[0028] In such a hermetic rotary compressor, the gas suction connection device according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com