Tire/wheel assembly body and supporting body for traveling with tire flat

A technology of running out of air and supporting body, which is applied in the direction of pneumatic tires, tire parts, vehicle parts, etc., can solve problems such as no effective countermeasures have been proposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

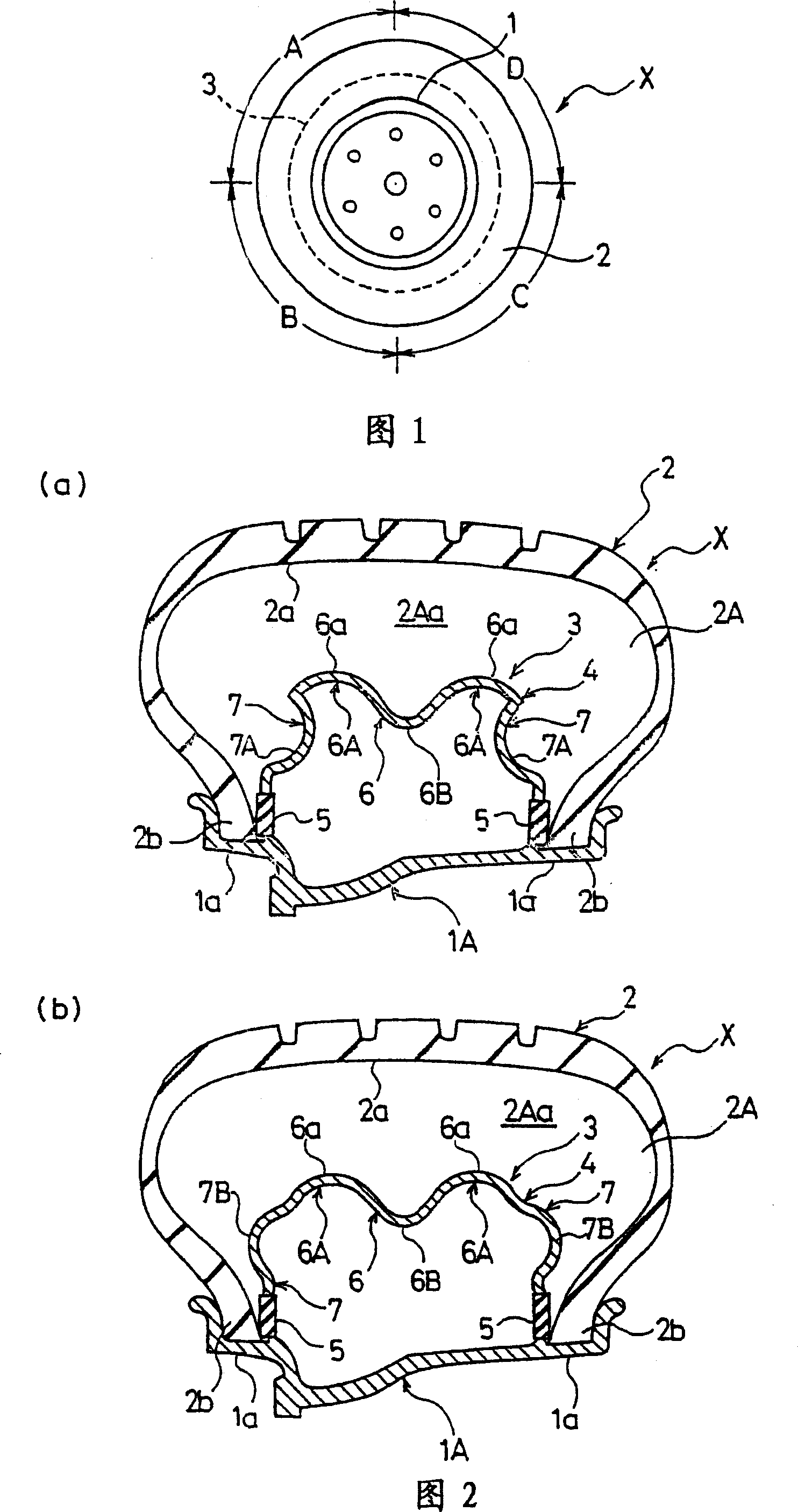

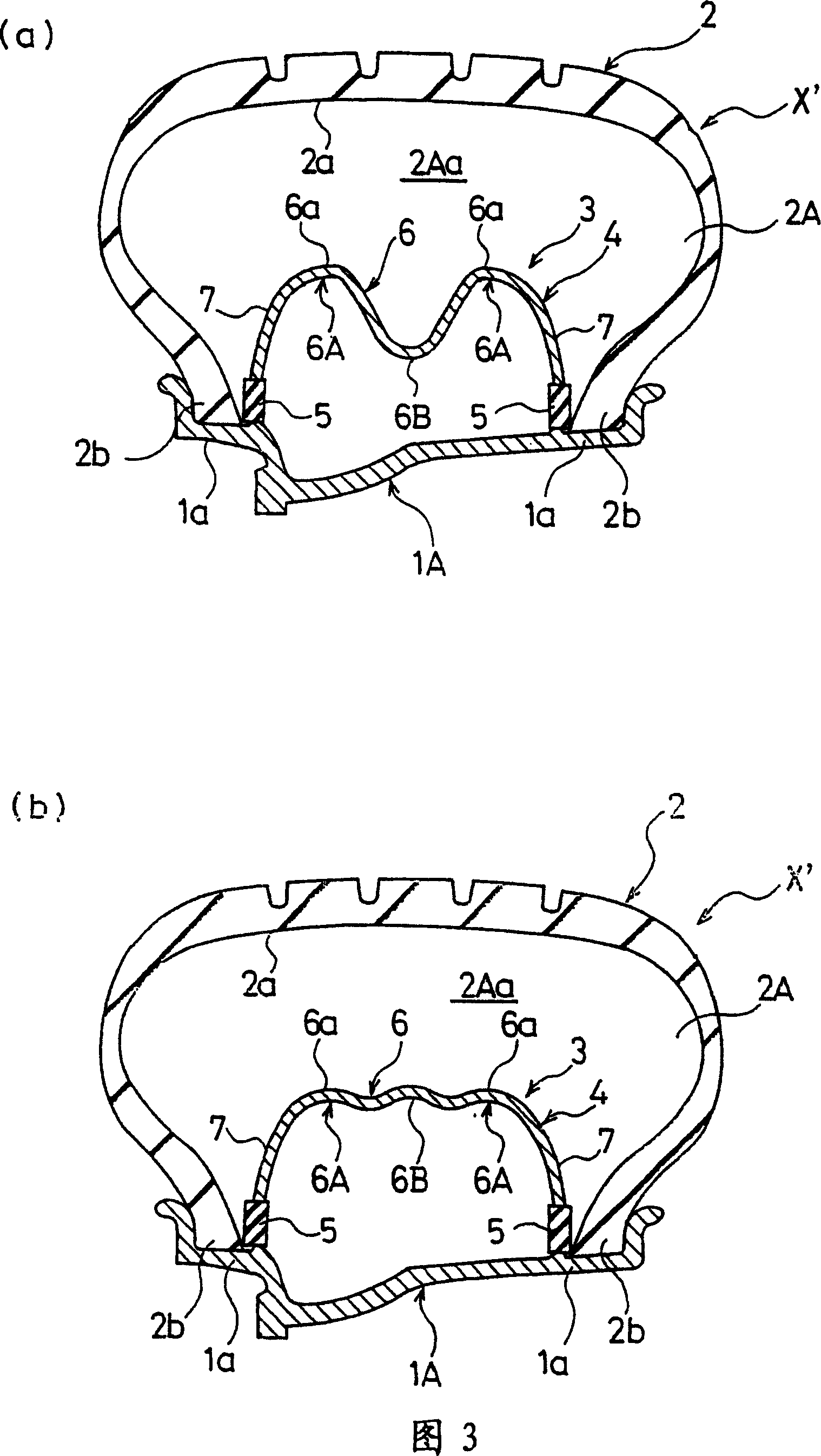

[0060] Set the tire size as 205 / 55R16, and set the rim size as 16×6 1 / 2JJ to be the same, and respectively make the ones with concavities and convexities provided on the legs of the annular shell, as shown in Figure 2 (A), The tire / wheel assembly 1 of the present invention (assembly 1 of the present invention) having the structure shown in (B) has concavities and convexities provided on the connecting portion of the supporting portion of the annular casing, as shown in FIG. 3(A), The tire / wheel assembly 2 of the present invention having the structure shown in (B) (the assembly 2 of the present invention), and in the tire / wheel assembly of the present invention, no unevenness is provided on the legs of the annular casing. Conventional tire / wheel assembly 1 (conventional assembly 1).

[0061] The cross-sectional area of the hollow portion of the tire / wheel assembly 1, 2 of the present invention has a maximum cross-sectional area greater than the minimum cross-sectional area by...

Embodiment 2

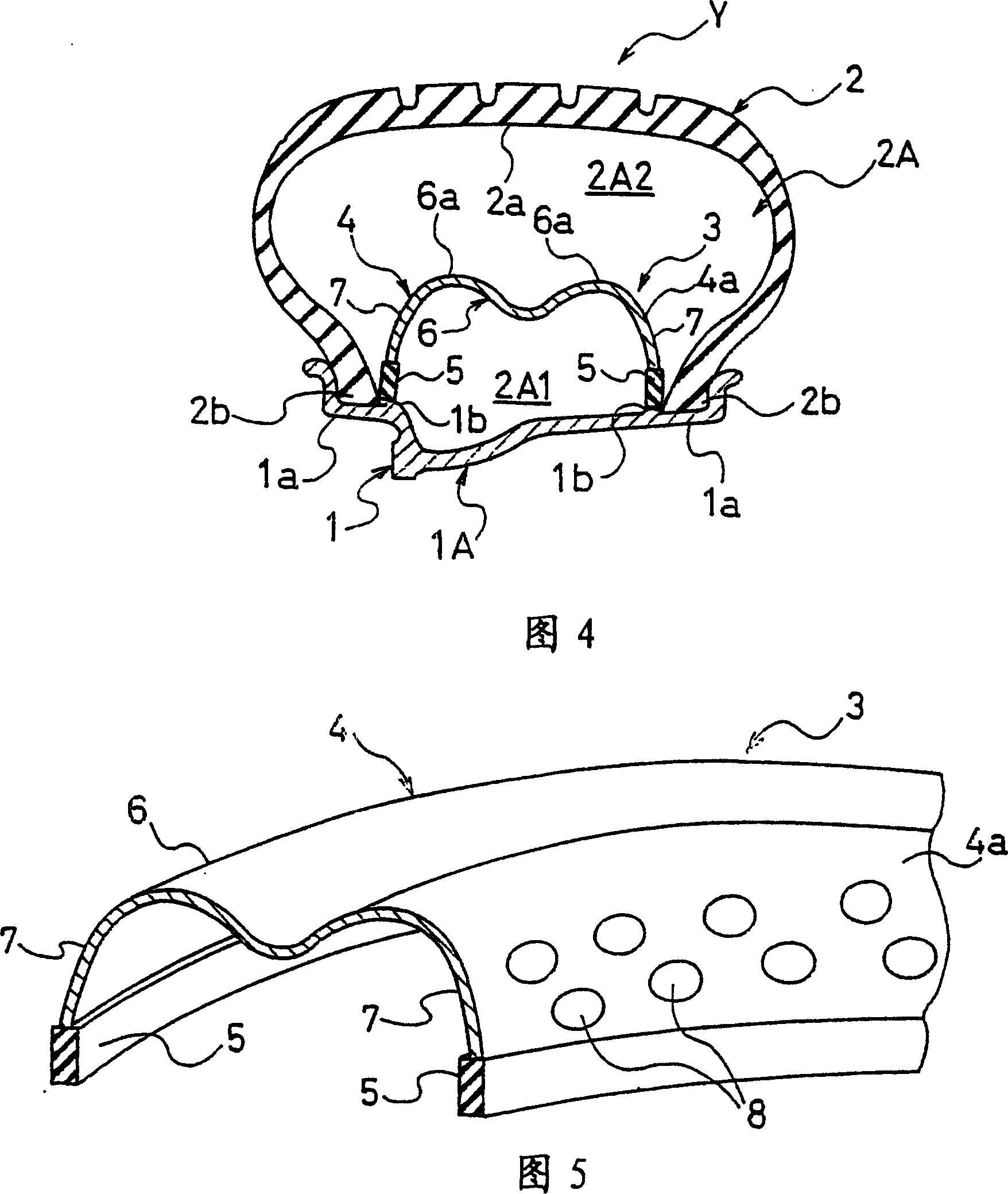

[0069] The tire size and rim size were set to be the same as in Example 1, and the maximum and minimum differences in the total opening area of the through holes between the regions that divided the annular casing 4 into equal parts were produced as shown in Table 2. Tire / wheel assemblies 3 to 5 of the present invention (assemblies of the present invention 3 to 5) and comparative tire / wheel assemblies 1 and 2 (comparative assemblies 1 and 2) of the present invention having the configuration of FIG. 4 , and no through holes are provided. The conventional tire / wheel assembly 2 (conventional assembly 2).

[0070] The total area of the openings of all the through holes of the tire / wheel assemblies 3 to 5 of the present invention and the comparative tire / wheel assemblies 1 and 2 is 0.5% of the area of the outer surface of the annular casing. identical.

[0071] After setting the air pressure to 200kPa, these test tire / wheel assemblies were mounted on a passenger car with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com