Method for controlling torgue transfer system

A torque transmission and torque technology, applied in the control device, the safety device of the power device control mechanism, the transmission device, etc., can solve the problem of slow speed adjustment and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

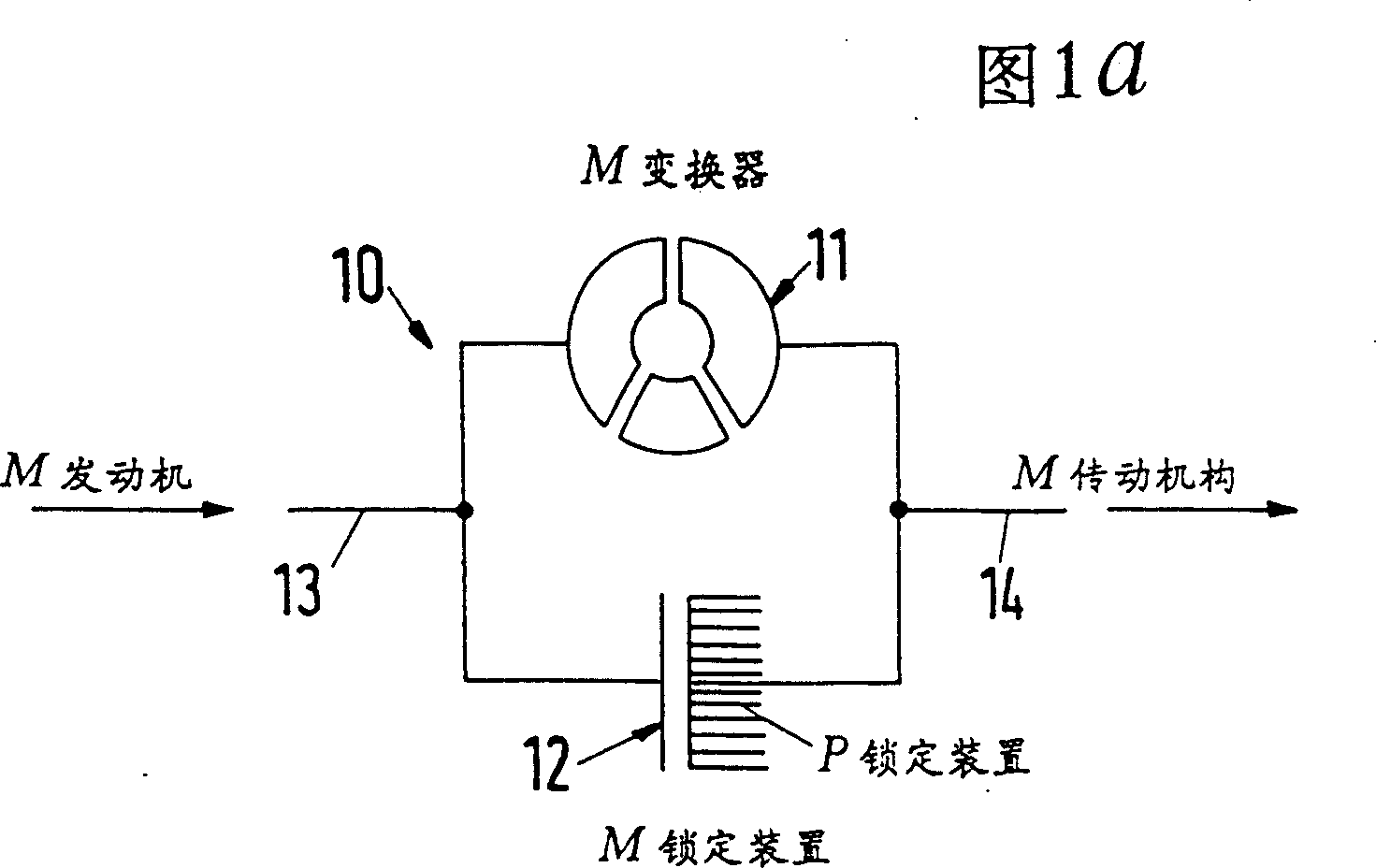

[0218] The torque transmission system 10 shown in FIGS. 1a and 2 comprises a torque converter 11 and a clutch clutch 12 which operates by the flow pressure method and which is bridged by the torque converter. The torque transmission system is connected to an internal combustion engine not shown via a shaft 13, which is only schematically indicated, and on the other side, the driven side, via a driven shaft 14 and a drive chain placed behind it. The automatic transfer mechanism connected and driven, the transfer mechanism is also not drawn.

[0219] As shown in Fig. 2 , the half-section principle diagram of the torque transmission system 10 and the pressure control principle diagram together, the torque converter 11 is equivalent to a conventional hydraulic torque converter. This hydraulic torque converter 11 is by a torque converter cover 16 that is connected with the driven device of internal combustion engine, a pump wheel 17 that forms torque converter housing together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com