Motor casing

A technology of outer shell and inner shell, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as lower production efficiency, loose bolts, and problems, so as to improve production efficiency, maintain stability, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

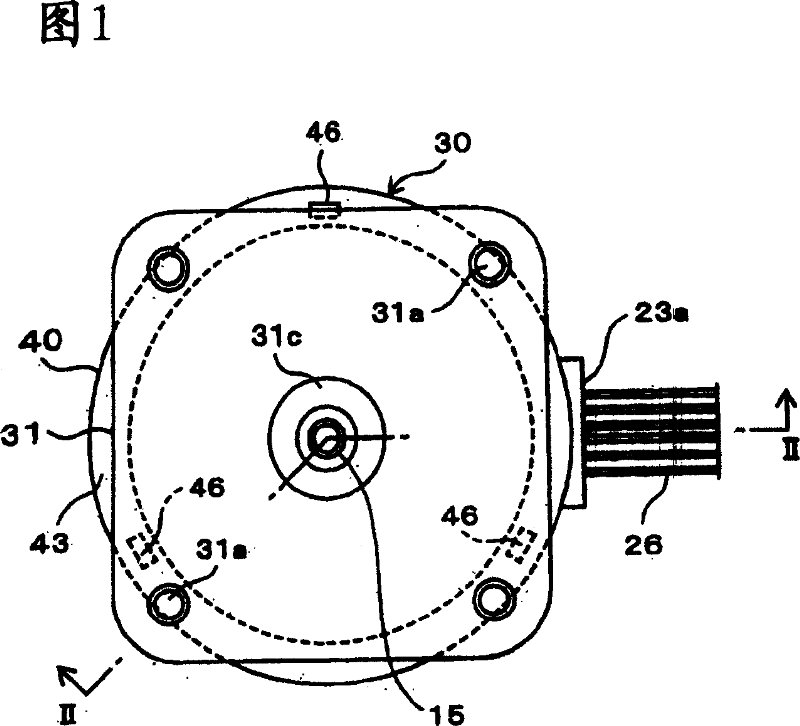

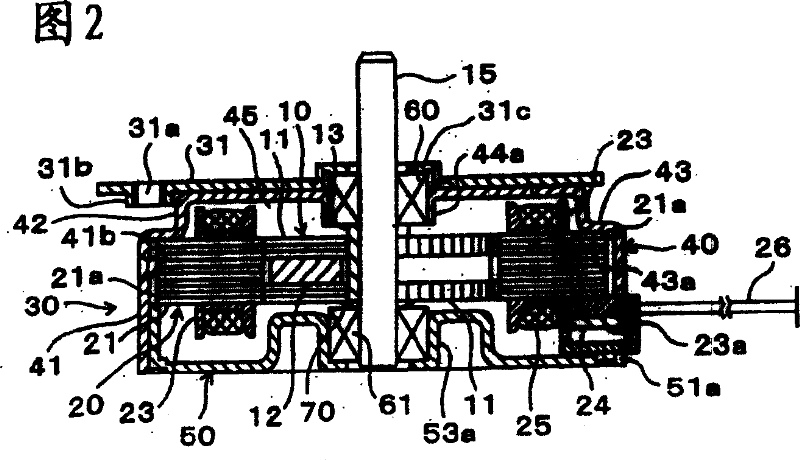

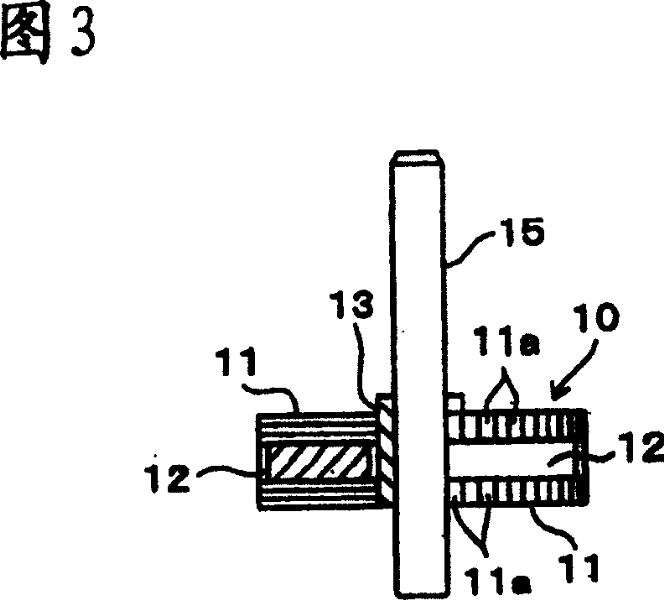

[0027] Embodiments of the present invention applied to a stepping motor will be described below with reference to the drawings. FIG. 1 is a top view of a stepping motor according to an embodiment of the present invention. FIG. 2 is a cross-sectional view along section II-II from FIG. 1 . In FIG. 2 , 10 is a rotor, 20 is a stator disposed around the rotor 10 , and 30 is a casing covering the rotor 10 and the stator 20 .

[0028] As shown in FIG. 2, the housing 30 is composed of a cylindrical outer housing (hereinafter referred to as the front housing) 40 and an inner housing (hereinafter referred to as the rear housing) mounted on the opening side of the front housing 40 at the bottom center of the figure. Body) 50 combined composition. , as can be seen in FIG. 1, a square front plate (joint portion) 31 is fixed to the top surface of the front case 40 by, for example, welding. For example, a through hole is formed by drilling processing at the corner of the front plate 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com