Dust filter for using in operations endangered by gases

A dust filter and dangerous technology, applied in the field of dry dust filter, can solve the problems of unmentioned solutions, and achieve the effect of reducing ignition and preventing electrostatic charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

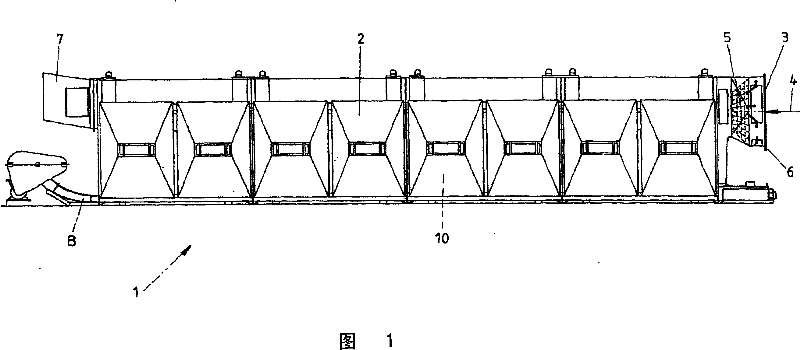

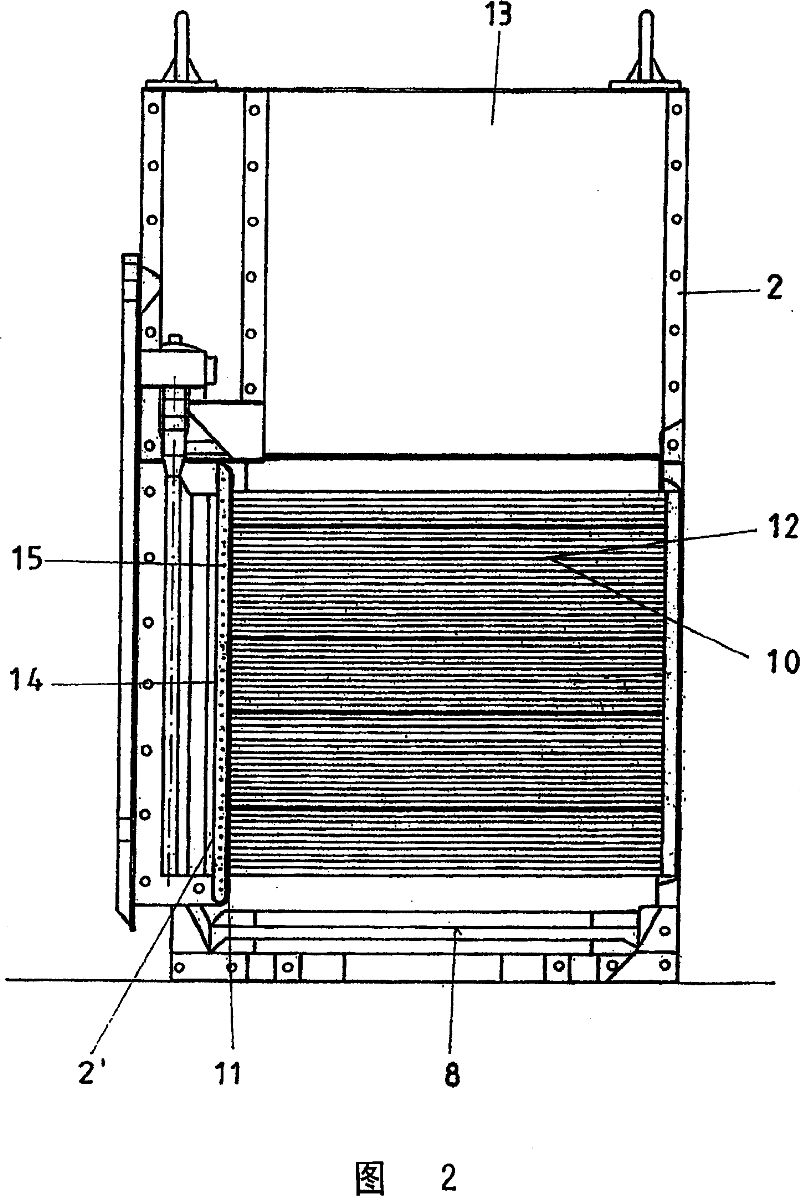

[0030] Figure 1 is a side view of a dry dust filter 1 assembled from individual elements. The assembled unit can be placed in the ground or also suspended from a monorail or other structure via the hooks visible above. The housings 2 of all these individual units are identical, with the filter inlet 3 having a coarse filter 5 for pre-dust removal, ie here the coarser fraction is separated from the air flow passing through. The direction of flow is indicated by 4 .

[0031] The filter inlet 3 has a connecting flange 6 which can be connected to a pre-separator which will be described in more detail below.

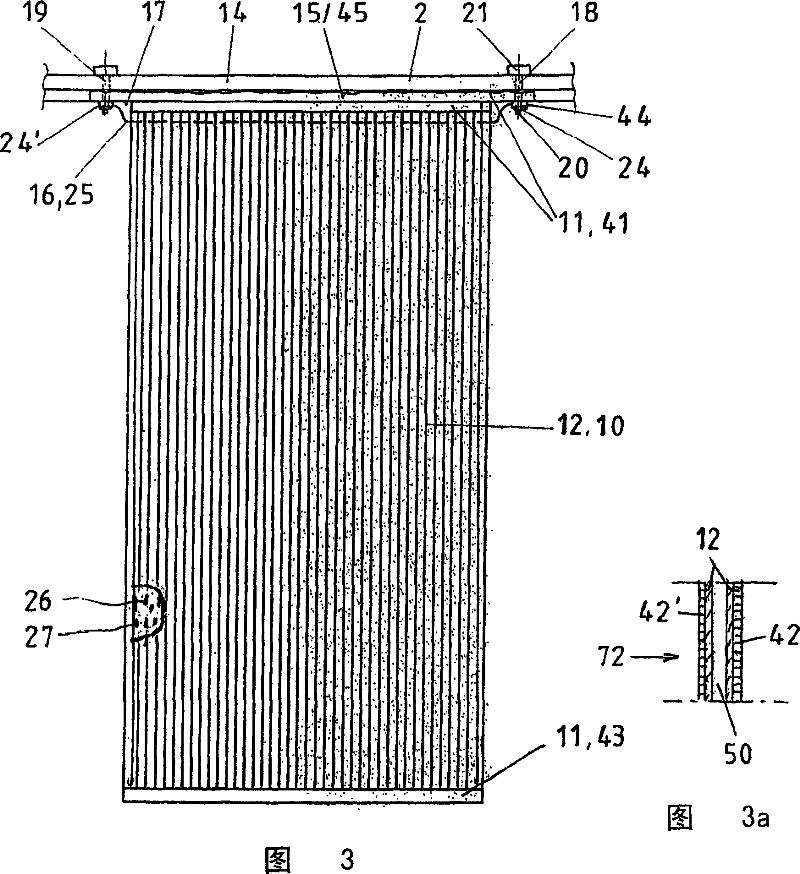

[0032] The filter outlet 7 forms the rear end of the housing 2, of which the shown dust filter 1 shows only one possibility. In the case of the housing 2 shown here, the cleaned wind flow exits at the filter outlet 7 . A plurality of filter elements 10 are arranged in the housing 2 . The filter elements are cleaned at regular intervals, the dust falling here falling into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com