Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Quickly align to working position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

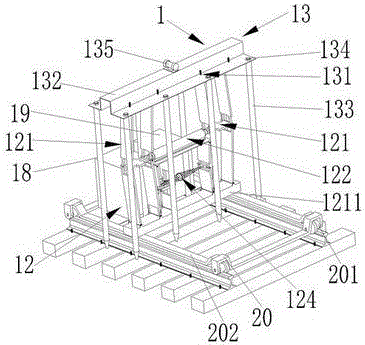

Small railway maintenance machine with shape recognition function

InactiveCN106676981AQuickly align to working positionEasy dischargeBallastwayRailway track constructionSprocketPush pull

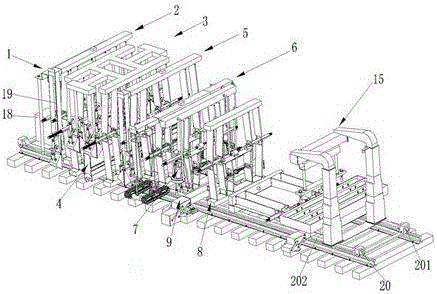

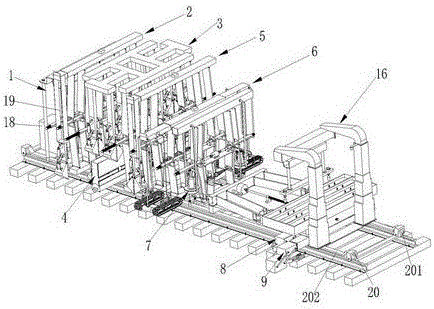

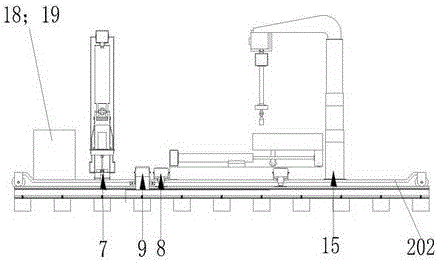

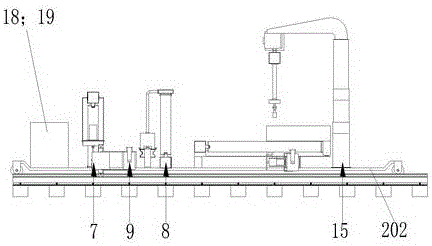

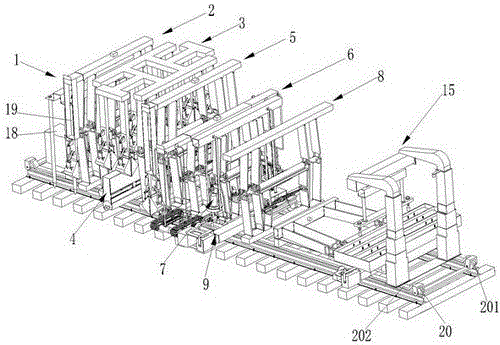

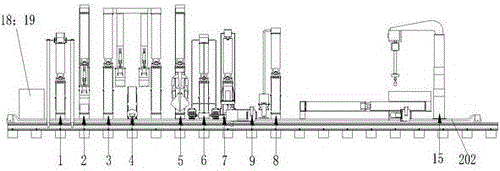

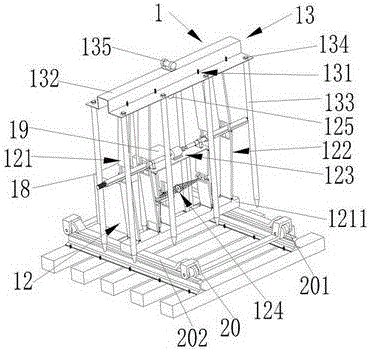

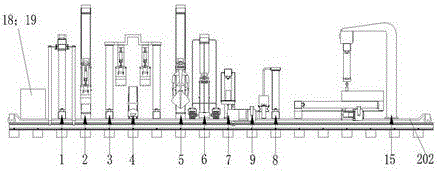

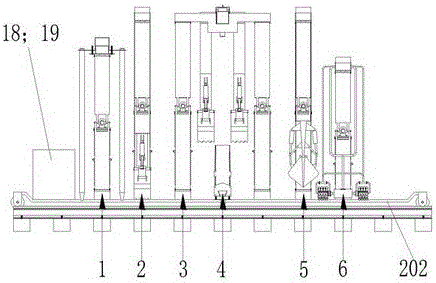

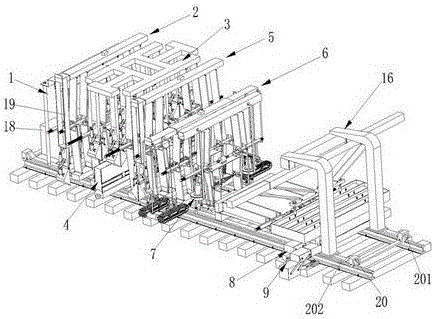

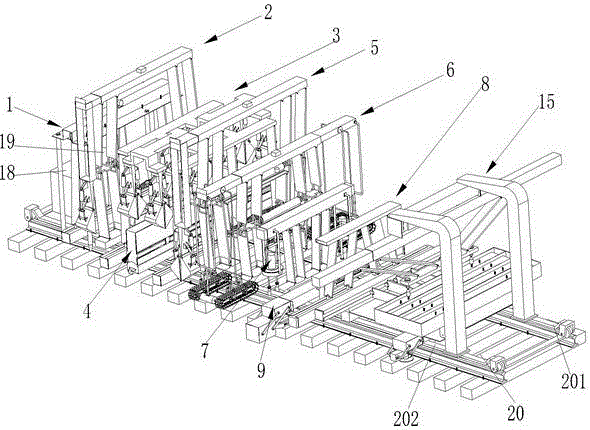

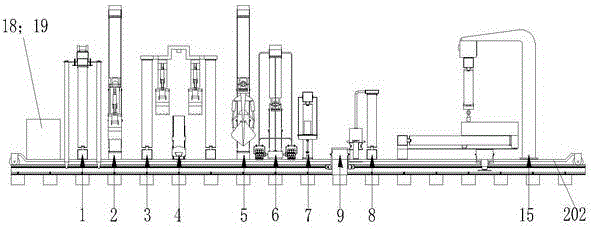

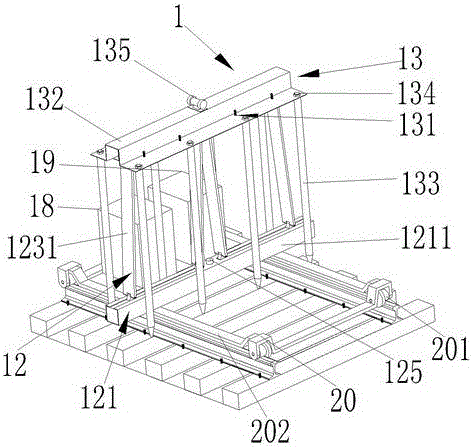

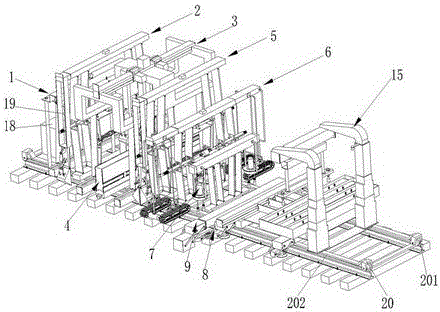

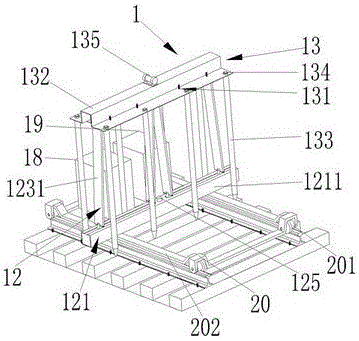

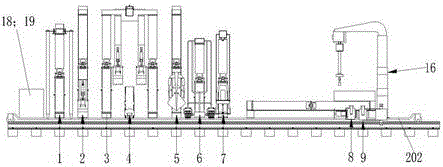

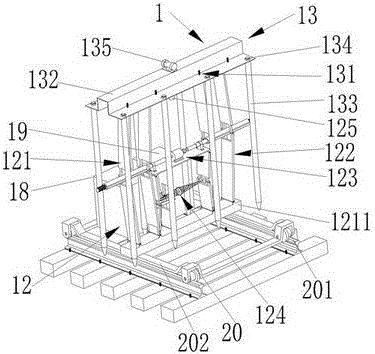

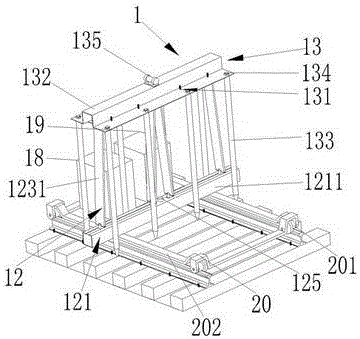

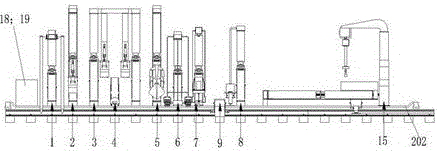

The invention discloses a small railway maintenance machine with a shape recognition function. The small railway maintenance machine comprises a tamping and ballast leveling device, a railway shoulder and ballast bed shape correction device, a grab bucket ballast clearing device, a ballast collection and discharge device, a sleeper end ballast clearing device, a sprocket ballast discharge device, a synchronous assembling and disassembling device for four nuts, a first rail lifting device, a shunting and sleeper push-pull device, a sleeper hanging device, an electric generator, a hydraulic system and control system cabinet and a rail car. The small railway maintenance machine has the advantages that working positions can be aligned rapidly; ballast on a ballast bed between sleepers, the outer sides of the sleeper ends and under steel rails can be discharged automatically, sand and soil in the ballast can be separated automatically, the ballast can be backfilled between the replaced sleepers to be tamped and leveled, and the shapes of railway shoulders and the ballast bed are repaired automatically; the four nuts can be assembled and disassembled synchronously, so that the fatigue life of bolts is prolonged, and connecting reliability between the sleepers and the rails is ensured; the shunting and sleeper push-pull device which is an integrated device is compact in structure and adaptive to various sleeper replacement operations in straight and curve rail sections, and accordingly high sleeper replacement efficiency is achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

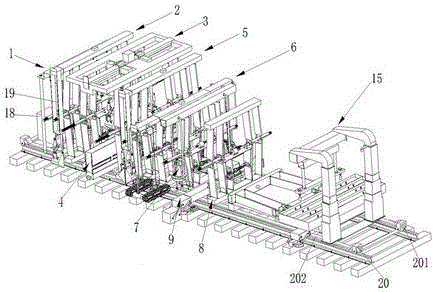

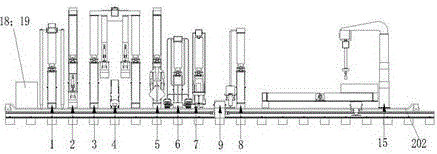

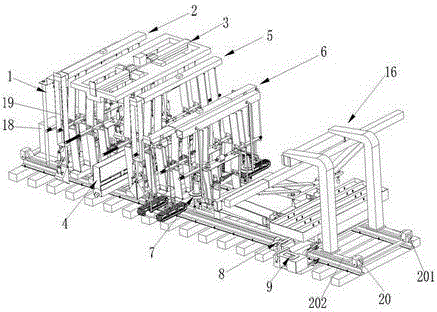

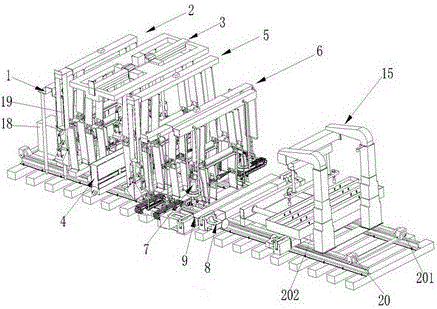

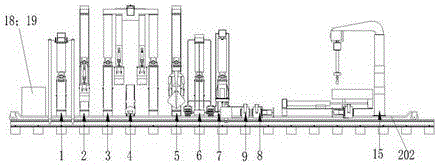

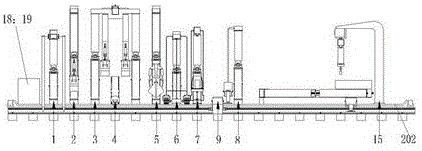

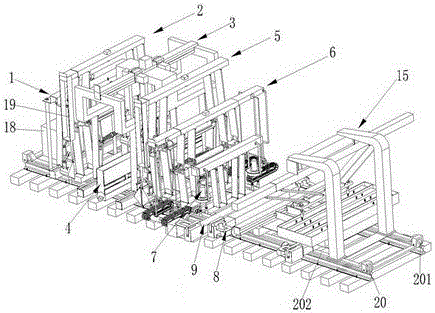

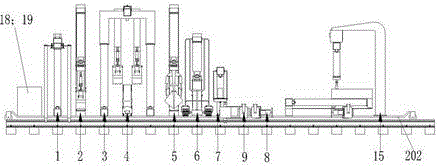

Railway maintenance mechanical-electrical-hydraulic integration machine with graph recognition function

InactiveCN106168008AQuickly align to working positionEasy dischargeRailway track constructionPush and pullControl system

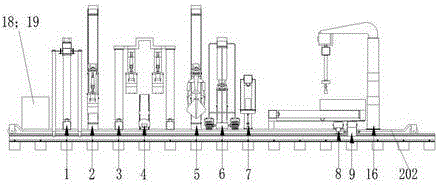

The invention discloses a railway maintenance mechanical-electrical-hydraulic integration machine with a graph recognition function. The machine is composed of a tamping and ballasting device, a railway shoulder and ballast bed shape correction device, a grab bucket stone removing device, a stone ballast collection and discharge device, a sleeper end stone removing device, a sprocket stone discharge device, a four-nut synchronous assembling and disassembling device, a rail lifting device, a swivel block and push-and-pull sleeper device, a sleeper hoisting device, an electric generator, a hydraulic system and control system case and a rail car. According to the railway maintenance mechanical-electrical-hydraulic integration machine with the graph recognition function, working devices can be rapidly aligned with working positions, stone ballast among sleepers, on the sleeper end outer sides and the ballast bed below steel rails is automatically discharged, sandy soil in the stone ballast is automatically separated, the stone ballast is automatically backfilled to the portion between the sleepers on the two sides of a replaced sleeper and tamped and leveled through vibration, and shapes of the railway shoulder and a ballast bed are automatically repaired; four-nut synchronous assembling and disassembling are achieved, the fatigue life of bolts is prolonged, and the reliability of connection of the sleepers and the steel rails is guaranteed; swivel blocks and push-and-pull sleepers form an integrated device, the structure is compact, the device is suitable for various work of straight and curve rail road section sleeper changing, and the working efficiency of sleeper changing is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

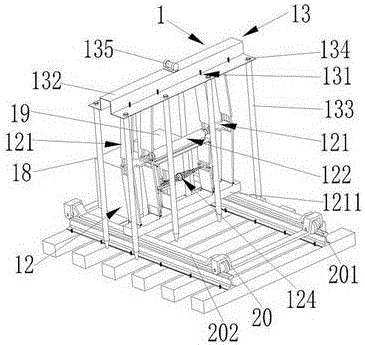

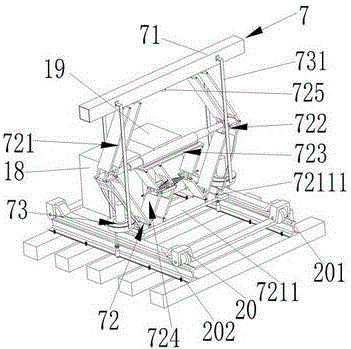

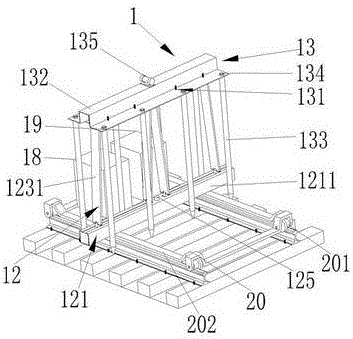

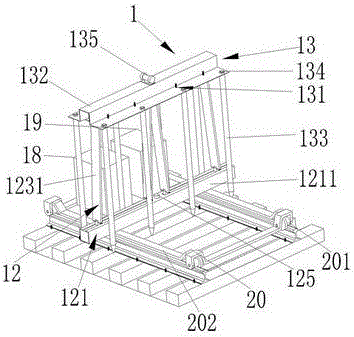

Sleeper changing machine having swing rail-lifting device

InactiveCN106320110AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionEngineeringMechanical engineering

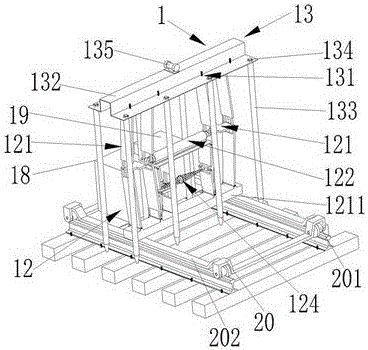

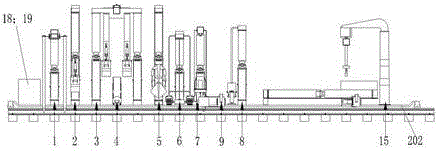

The invention discloses a sleeper changing machine having a swing rail-lifting device. The sleeper changing machine consists of a synchronous four-nut mounting-dismounting device, a rail-lifting device, a sleeper turning, pushing and pulling device, a sleeper hoisting device, a generator, a hydraulic system, a control system box and a rail car. The rail car is provided with multiple trundles and two longitudinal beams, the synchronous four-nut mounting-dismounting device, the rail-lifting device, the sleeper turning, pushing and pulling device, the sleeper hoisting device, the generator, the hydraulic system and the control system box are arranged on the two longitudinal beams of the rail car, and the rail car is dragged by an engineering vehicle. The device can rapidly align a working device to a working position, achieves synchronous four-nut mounting and dismounting and makes four nuts consistent in pre-tightening force, prolongs the service life of bolts, ensures the sleeper and steel rail connecting reliability, performs rapid sleeper hoisting and placement works, is suitable for linear and curved railway section sleeper changing work, is simple and compact in structure, convenient to operate and high in sleeper changing work efficiency and is automatically controlled, and the sleeper turning, pushing and pulling device is an integrated device.

Owner:KUNMING UNIV

Automatic sleeper replacing machine with tamping and ballasting device

InactiveCN106381778AQuickly align to working positionEasy dischargeBallastwayRailway track constructionControl systemSprocket

The invention discloses an automatic sleeper replacing machine with a tamping and ballasting device. The automatic sleeper replacing machine is composed of the tamping and ballasting device, a shoulder and ballast bed trimming device, a grab bucket stone-removing device, a ballast collecting and discharging device, a sleeper end stone-removing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a rail lifting device, a sleeper-rotating and sleeper pushing-and-pulling device, a sleeper hoisting device, a generator, a hydraulic system and control system cabinet and a rail car. According to the automatic sleeper replacing machine, the working devices can be aligned with working positions rapidly; ballast between sleepers, ballast outside the ends of the sleepers and ballast on a ballast bed under steel rails are automatically discharged, sand in the ballast is automatically separated, the ballast is automatically backfilled into the space between sleepers on the two sides of a replaced sleeper, tamped and flattened through vibration, and the shapes of shoulders and the ballast bed are automatically restored; four-nut synchronous assembling and disassembling are achieved, the fatigue lives of bolts are prolonged, and connection reliability of the sleepers and the steel rails is guaranteed; and the sleeper-rotating and sleeper pushing-and-pulling device is an integrated device, is compact in structure, adapts to various operations of sleeper replacing of linear and curved railway sections and is high in sleeper replacing efficiency.

Owner:KUNMING UNIV

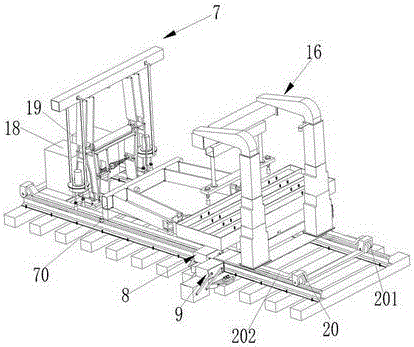

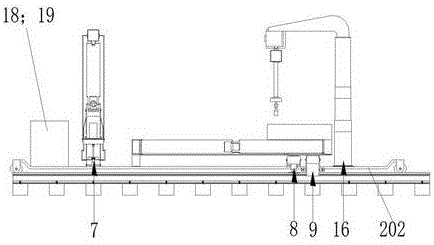

Machine automatic rapid sleeper-changing device

InactiveCN106498819AQuickly align to working positionConsistent preloadTrack superstructureRailway track constructionAutomatic controlControl system

The invention discloses a machine automatic rapid sleeper-changing device. The device is composed of a four-nut synchronous assembling / disassembling device, a first track hoisting device, a track-transferring and sleeper pulling-pushing device, a sleeper overhead-hoisting device, a power generator, a hydraulic system and control system box and a track car, wherein multiple truckles and two carlings are arranged on the track car; the four-nut synchronous assembling / disassembling device, the first track hoisting device, the track-transferring and sleeper pulling-pushing device, the sleeper overhead-hoisting device, the power generator and the hydraulic system and control system box are arranged on the two carlings of the track car; and the track car is towed by an engineering truck. The device disclosed by the invention can rapidly align a working device with a working position; four nuts can be synchronously assembled / disassembled, so that the pre-tightening forces of the four nuts are consistent, the fatigue life of a bolt is prolonged, and the connection reliability of the sleeper and a steel rail is guaranteed; the sleeper can be rapidly overhead-hoisted and placed to work; the device is adapted to the sleeper-changing work of linear and curve track sections; the track-transferring and sleeper pulling-pushing device is an integrated device; the device is simple and compact in structure, realizes automatic control, and is convenient for operation, and sleeper-changing working efficiency is high.

Owner:KUNMING UNIV

Automatic sleeper changing machine

InactiveCN106351084AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses an automatic sleeper changing machine which is composed of a tamping and ballasting device, a runway shoulder and ballast bed shape correcting device, a grab bucket rock removing device, a ballast concentrated discharge device, a sleeper end rock removing device, a sprocket rock discharge device, a four-nut synchronous assembling and detaching device, a first rail lifting device, a retracking and sleeper push-pull device, a sleeper hoisting device, a power generator, a hydraulic system and control system box and a rail car. Working devices can be rapidly aligned with working positions; ballast between sleepers, on the outer sides of sleeper ends and on a ballast bed below steel rails is automatically discharged, sand and soil in the ballast are automatically separated, the ballast is automatically backfilled between the two sides of changed sleepers to be tamped and vibrated flat, and the shape of runway shoulders and ballast beds is automatically repaired; four nuts are synchronously detached and assembled, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the steel rails is ensured; the retracking and sleeper push-pull device is an integrated device and is compact in structure, suitable for all work of linear and curved rail section sleeper changing and high in sleeper changing work efficiency.

Owner:KUNMING UNIV

Small railway maintenance equipment capable of removing and backfilling ballast

InactiveCN106283977AQuickly align to working positionEasy dischargeBallastwayAutomatic controlSprocket

The invention discloses small railway maintenance equipment capable of removing and backfilling ballast. The equipment is composed of a tamping and blast leveling device, a runway shoulder and ballast bed shape correction device, a grab bucket stone removal device, a ballast centralized removal device, a sleeper end stone removal device, a sprocket stone removal device and a rail car. A working device can be aligned with a working position quickly, ballast between sleepers can be removed quickly, and sandy soil in ballast can be automatically removed at the same time; ballast on a ballast bed outside a sleeper end can be quickly removed; ballast on a ballast bed below a rail can be quickly removed; ballast can be quickly backfilled in the space between replaced sleepers on two sides; the shape of a runway shoulder and a ballast bed can be quickly corrected; ballast backfilled in the space between the replaced sleepers can be quickly tamped and leveled; the equipment can be adapted to linear and bent rail sections for ballast removal and backfilling; automatic control can be achieved, operation is convenient, and ballast removing and backfilling efficiency is high.

Owner:KUNMING UNIV

Multifunctional railway maintenance automated machine

InactiveCN106351082AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a multifunctional railway maintenance automated machine which comprises a tamping ballast leveling device, a runway shoulder and ballast bed shape repair device, a grab bucket stone removing device, a stone ballast collecting and discharging device, a sleeper end stone removing device, a sprocket stone discharging device, a four-nut synchronous assembly and disassembly device, a first rail lifting device, a sleeper rotation and push-pull device, a sleeper lifting device, a power generator, a hydraulic system and control system box and a rail car. A working device can be rapidly aligned to a working position, stone ballasts in space among sleepers, on ballast beds on the outer sides of sleeper ends and on ballast beds below steel rails are automatically discharged, sandy soil in the stone ballasts is automatically separated, the stone ballasts are automatically backfilled in the space between two sides of each replaced sleeper, tamped and leveled, shapes of a runway shoulder and a ballast bed are automatically repaired, four nuts are synchronously assembled and disassembled, the fatigue life of a bolt is prolonged, connection reliability of the sleepers and the steel rails is ensured, and the sleeper rotation and push-pull device is an integrated device which is compact in structure, adaptable to various operations of sleeper replacing of linear and curved rail road sections and high in transition efficiency.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Pillow changing machine with chain-tooth stone discharging device

InactiveCN106337339AQuickly align to working positionEasy dischargeBallastwayTrack superstructurePush pullEngineering

The invention discloses a sleeper replacement machine with chain-tooth stone discharging device, which comprises a tamping and leveling device, a shoulder and a road bed modification device, a grab stone clearing device, a ballast collecting and discharging device, a pillow end stone discharging device, a chain-tooth stone discharging device, a four-nut synchronous mounting and dismounting device, a first rail lifting device, a transition and push-pull sleeper device, a trolley sleeper device, a generator, a hydraulic system and a control system box and a rail car. The present invention can quickly work is directed towards the work position; automatic discharge between the sleepers, the sleepers and rails with the outboard end below the ballast bed of ballast, the ballast in the automatic separation of the sand, ballast is backfilled to automatically change the sleeper has been in the places between two sides of the flat stamping, auto repair and a ballast bed shoulder shape; four of the nut assembly and disassembly, to increase the fatigue life of the sleeper and the rail to ensure the reliability of the connection; the pillow the sleeper and the push-pull operation of the integrated device, compact structure, the adaptation of straight and curved rail sections of the work of replacement, the replacement of high working efficiency.

Owner:KUNMING UNIV

Mechanical-electrical-hydraulic integration sleeper replacement machine

InactiveCN106223134AQuickly align to working positionEasy dischargeBallastwayTrack superstructurePush and pullSprocket

The invention discloses a mechanical-electrical-hydraulic integration sleeper replacement machine. The mechanical-electrical-hydraulic integration sleeper replacement machine is composed of a tamping ballast flattening device, a road shoulder and road bed shape repairing device, a grab bucket stone clearing device, a ballast concentrated discharging device, a sleeper end stone clearing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a first rail lifting device, a sleeper rotating, pushing and pulling device, a sleeper hoisting and conveying device, a generator, a hydraulic system and control system box and a rail vehicle. According to the mechanical-electrical-hydraulic integration sleeper replacement machine, a working device can be quickly aligned with a working position; ballast located between sleepers, on the outer sides of the ends of the sleepers and on a road bed under a steel rail is automatically discharged, sandy soil in the ballast is automatically separated, the ballast is automatically placed between sleepers on the two sides of replaced sleepers in a backfilling mode, and then tamped and flattened in a vibration mode, and the shape of a road shoulder and the shape of the road bed are automatically repaired; four nuts can be assembled and disassembled synchronously, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the steel rail is ensured; and the sleeper rotating, pushing and pulling device is an integrated device, the structure is compact, the sleeper replacement machine adapts to various jobs of sleeper replacement of linear and curved rail sections, and the sleeper replacement working efficiency is high.

Owner:KUNMING UNIV

Small multi-functional railway maintenance machine

InactiveCN106283982AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a small multi-functional railway maintenance machine, which is composed of a tamping ballasting device, a runway shoulder and ballast bed shape repairing device, a clam bucket ballast clearing device, a ballast collecting and discharging device, a sleeper end ballast clearing device, a sprocket ballast discharging device, a four nut synchronous assembly and disassembly device, a track lifting device, a retracking and sleeper push-pull device, a sleeper hoisting and swinging device, a generator, a hydraulic system and control system box and a rail car. According to the invention, the working devices can be aligned with the working positions quickly; ballast between sleepers, on the outer sides of sleeper ends and on a ballast bed below the rail is automatically discharged; sandy soil in the ballast is automatically separated, the ballast is automatically backfilled between sleepers on the both sides of the already-exchanged sleeper to be tamped and vibrated, and the shapes of the runway shoulder and the ballast bed are automatically repaired; four nuts are assembled and disassembled synchronously, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the rail is guaranteed; and the retracking and sleeper push-pull device is an integrated device, the structure is compact, various tasks of sleeper exchanging at straight and curved rail sections are adapted to, and the working efficiency of sleeper exchanging is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Replacement sleeper machine with grab stone cleaning device

InactiveCN106337341AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a replacement sleeper machine with a clamshell stone cleaning device. The sleeper machine is composed of a tamping and leveling device, a shoulder and a road bed modification device, a grab stone clearing device, a ballast collecting and discharging device, a pillow end stone discharging device, a chain tooth stone discharging device, a four-nut synchronous mounting and dismounting device, a first rail lifting device, a transition and push-pull sleeper device, a trolley sleeper device, a generator, a hydraulic system and a control system box and a rail car. The present invention can quickly work directly towards the work position; automatic discharge between the sleepers, the sleepers and rails with the outboard end below the ballast bed of ballast, the ballast in the automatic separation of the sand, ballast is backfilled to automatically change the sleeper has been in the places between two sides of the flat stamping, auto repair and a ballast bed shoulder shape; four of the nut assembly and disassembly, to increase the fatigue life of the sleeper and the rail to ensure the reliability of the connection; the pillow the sleeper and the push-pull operation of the integrated device, compact structure, the adaptation of straight and curved rail sections of the work of replacement, the replacement of high working efficiency.

Owner:KUNMING UNIV

Ballast discharging and filling mechanized device

InactiveCN106223135AQuickly align to working positionEasy dischargeBallastwayTrack superstructureAutomatic controlSprocket

The invention discloses a ballast discharging and filling mechanized device. The ballast discharging and filling mechanized device is composed of a ballast tamping and flattening device, a road shoulder and road bed shape repairing device, a grab bucket stone clearing device, a ballast concentrated discharging device, a sleeper end stone clearing device, a sprocket stone discharging device and a rail vehicle. According to the ballast discharging and filling mechanized device, a working device can be quickly aligned with a working position; ballast located between sleepers, can be quickly discharged, and meanwhile sandy soil in the ballast is automatically removed; ballast in the positions, on the outer sides of the ends of the sleepers, of a road bed can be quickly removed; ballast in the position, under a steel rail, of the road bed can be quickly removed; ballast can be quickly backfilled between sleepers on the two sides of replaced sleepers, and the shape of a road shoulder and the shape of the road bed can be quickly repaired; the ballast backfilled to the position between the replaced sleepers can be quickly tamped and flattened in a vibration mode; the ballast discharging and filling mechanized device can adapt to ballast discharging and filling work of linear and curved rail sections; and automatic control can be achieved, operation is convenient, and the working efficiency of ballast discharging and filling is high.

Owner:KUNMING UNIV

Railway maintenance small-sized machine with shoulder shaping apparatus

InactiveCN106351080AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemEngineering

The invention discloses a railway maintenance small-sized machine with a shoulder shaping apparatus, comprising a tamping and ballast leveling apparatus, a ballast shoulder and bed shaping apparatus, a grab destoning apparatus, a rock ballast collecting and discharging apparatus, a sleeper end destoning apparatus, a chain-tooth rock discharging apparatus, a four-nut synchronous handling apparatus, a rail lifting apparatus, a sleeper transfer and sliding apparatus, a sleeper hoisting apparatus, a power generator, a hydraulic system and control system case and a track car. Working apparatuses can be aligned to working positions accurately; rock ballast is automatically discharged from the space between sleepers, ballast beds on the outside of sleeper ends and the ballast beds below tracks, sandy soil in the rock ballast is automatically separated and is automatically applied back to fill the space between sleepers on two sides of a renewed sleeper before being tamped, the shape of the ballast shoulder and bed is automatically restored; four nuts are handled in sync, fatigue life of a bolt is prolonged, and sleeper and track connection reliability is guaranteed; the sleeper transfer and sliding apparatus is an integrated apparatus with compact structure, adapting to various sleeper renewing workers at linear and curved rail sections, and sleeper renewing efficiency is improved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Mechanical-electrical-hydraulic integrated rapid sleeper changing device

InactiveCN106283976AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a mechanical-electrical-hydraulic integrated rapid sleeper changing device. The mechanical-electrical-hydraulic integrated rapid sleeper changing device comprises a tamping and ballast leveling device, a runway shoulder and ballast bed profile modification device, a grab bucket stone clearing device, a stone ballast collection and discharge device, a sleeper end stone clearing device, a sprocket stone discharge device, a four-nut synchronous assembling and disassembling device, a first rail lifting device, a sleeper transferring and push-pull device, a sleeper hoisting device, a generator, a hydraulic system and control system box and a rail car. By means of the machine, work devices can be rapidly aligned in the work positions; stone ballast between sleepers, on the outer side of the sleeper end and on a ballast bed below a steel rail is automatically discharged, sandy soil in the stone ballast is automatically separated, a space between the sleepers which have been changed on two sides is automatically backfilled with the stone ballast, the stone ballast is tamped and leveled, and the shapes of a runway shoulder and the ballast bed are automatically repaired; four nuts are synchronously assembled and disassembled, the fatigue life of bolts is prolonged, and the reliability of connection of the sleepers and the steel rail is guaranteed; the sleeper transferring and push-pull device is an integrated device, is compact in structure and adapts to various works for sleeper changing in straight-line and curved rail sections, and the sleeper changing work efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Sleeper changing machine provided with sleeper rotation and pushing-pulling integrated device

InactiveCN106436506AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a sleeper changing machine provided with a sleeper rotation and pushing-pulling integrated device. The sleeper changing machine is composed of a tamping and ballasting device, a rail shoulder and ballast bed correction device, a grab bucket stone removing device, a ballast collection and discharge device, a sleeper end stone removing device, a sprocket stone discharge device, a four-nut synchronous mounting and dismounting device, a first rail lifting device, the sleeper rotation and pushing-pulling device, a sleeper hoisting device, an electric generator, a hydraulic system and control system cabinet and a rail car. According to the sleeper changing machine, a work device can be quickly aligned with a work position; ballast, located between sleepers, outside sleeper ends and under steel rails, of a ballast bed is automatically discharged, sandy soil in the ballast is automatically separated, the ballast is automatically backfilled to the position between sleepers on the two sides of a changed sleeper, tamped and vibrated to be flat, and the shapes of a rail shoulder and the ballast bed are automatically restored; synchronous mounting and dismounting of four nuts are achieved, the fatigue lives of bolts are prolonged, and the connection reliability of the sleepers and the steel rails is ensured; and the sleeper rotation and pushing-pulling device is an integrated device and is compact in structure, suitable for various work of sleeper changing at linear and curve rail sections and high in sleeper changing efficiency.

Owner:KUNMING UNIV

Sleeper changer with grab bucket stone removing device

InactiveCN106544931AQuickly align to working positionEasy dischargeBallastwayRailway track constructionPush and pullControl system

The invention discloses a sleeper changer with a grab bucket stone removing device. The sleeper changer is composed of a tamping and ballast leveling device, a runway shoulder and ballast bed shape correcting device, the grab bucket stone removing device, a ballast collecting and discharging device, a sleeper end stone removing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a first rail lifting device, a transfer rail and sleeper pushing and pulling device, a sleeper lifting device, a generator, a hydraulic system, a control system box and a rail car. The sleeper changer disclosed by the invention can quickly align the working position of a working device, automatically discharge ballasts among the sleepers, on the outer sides of the sleeper ends and in the ballast bed below the rail, automatically separate sandy soil in the ballast, automatically backfill the ballast between two sides of the changed sleeper to be tamped and leveled and automatically repair the shapes of the runway shoulder and ballast bed; four nuts are synchronous assembled and disassembled, the fatigue lives of the bolts are prolonged, and the connecting reliability of the sleeper and the rail is ensured; the transfer rail and the push-pull sleeper are an integrated device, so that the sleeper changer is compact in structure, suitable for various work of changing the sleepers in straight line and curved line rail sections, and high in sleeper changing working efficiency.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Automatic sleeper changing machine having image recognition function

InactiveCN106320108AQuickly align to working positionEasy dischargeBallastwayRailway track constructionControl systemEngineering

The invention discloses an automatic sleeper changing machine having an image recognition function. The automatic sleeper changing machine consists of a tamping and ballast flattening device, a rail shoulder and rail bed reshaping device, a grab bucket stone-clearing device, a ballast collecting and discharging device, a sleeper end stone-clearing device, a chain tooth stone discharging device, a synchronous four-nut mounting and dismounting device, a rail lifting device, a rail turning and sleeper pushing and pulling device, a sleeper hoisting device, a generator, a hydraulic system and control system box and a rail car. The automatic sleeper changing machine can rapidly align working devices to working positions, automatically discharges out ballast between sleepers, on the outer side of the sleeper ends and on a rail bed under steel rails, automatically separates sandy soil in the ballast, automatically backfills the ballast between the changed sleepers on two sides for tamping and ballast flattening, automatically repairs the shapes of rail shoulders and the rail bed, achieves synchronous four-nut mounting and dismounting, prolongs the service life of bolts, ensures the reliability of sleeper and steel rail connection, is compact in structure and high in sleeper changing work efficiency and adapts to various sleeper changing works of linear and curved rail sections, and the rail turning and sleeper pushing and pulling device is an integrated device.

Owner:NANJING UNIV OF SCI & TECH

Small railway maintenance equipment with transversely-moving grab bucket stone clearing device

InactiveCN106283992AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemSprocket

The invention discloses small railway maintenance equipment with a transversely-moving grab bucket stone clearing device. The equipment is composed of a tamping and ballasting device, a railway shoulder and railway bed shaping device, the grab bucket stone clearing device, a concentrated stone ballast discharging device, a sleeper end stone clearing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a rail lifting device, a rail rotating and sleeper pushing and pulling device, a sleeper hoisting and swinging device, an electric generator, a hydraulic system and control system box and a rail car. According to the small railway maintenance equipment with the transversely-moving grab bucket stone clearing device, the working device can be quickly aligned with the working position; stone ballasts between sleepers, stone ballasts outside the sleeper ends and stone ballasts in a railway bed under steel rails are automatically discharged, sandy soil in the stone ballasts is automatically separated, the stone ballasts are automatically backfilled to the position between the two sides of replaced sleepers to be tamped and ballasted, and the shapes of railway shoulders and the railway bed are automatically restored; four nuts are synchronously assembled and disassembled, therefore, the fatigue life of bolts is prolonged, and the reliability of connection between the sleepers and the steel rails is guaranteed; the rail rotating and sleeper pushing and pulling device is an integrated device, the structure is compact, various work of straight and curve steel rail section sleeper replacement can be met, and the sleeper replacing work efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Mechanic-electronic-hydraulic integrated sleeper replacing machine with lateral-moving grab bucket stone removing device

InactiveCN106351083AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a mechanic-electronic-hydraulic integrated sleeper replacing machine with a lateral-moving grab bucket stone removing device. The mechanic-electronic-hydraulic integrated sleeper replacing machine is composed of a tamping ballasting device, a track shoulder and track bed shaping device, the grab bucket stone removing device, a ballast collecting and discharging device, a sleeper end stone removing device, a sprocket stone discharging device, a four-nut synchronous assembly and disassembly device, a track lifting device, a retracking and sleeper pushing-pulling device, a sleeper hoisting device, a power generator, a hydraulic system, a control system and a track car. The working devices can be rapidly aligned with working positions; ballast at the positions between sleepers, on the outer sides of sleeper ends and on track beds below steel tracks is automatically discharged, sandy soil in the ballast is automatically separated, the ballast is automatically backfilled to the positions between sleeper bodies on the two sides of replaced sleepers, and the shapes of track shoulders and the track beds are automatically restored; synchronous assembly and disassembly of four nuts are achieved, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the steel tracks is guaranteed; the retracking and sleeper pushing-pulling device is an integrated device, and the mechanic-electronic-hydraulic integrated sleeper replacing machine is compact in structure, suitable for various operations of sleeper replacement of linear or curved track road segments and high in sleeper replacing working efficiency.

Owner:KUNMING UNIV

Sleeper replacing machine with sleeper end stone removing device

InactiveCN106320105AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a sleeper replacing machine with a sleeper end stone removing device. The sleeper replacing machine is composed of a ramming ballast leveling device, a runway shoulder and ballast bed shaping device, a grab bucket stone removing device, a ballast collecting and discharging device, the sleeper end stone removing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a first rail lifting device, a rail rotating and sleeper push-pull device, a sleeper hoisting device, an electric generator, a hydraulic system and control system box and a rail car. According to the sleeper replacing machine, working devices can be quickly aligned to working positions; ballast between sleepers, on the outer sides of the sleeper ends and a ballast bed below a steel rail can be automatically discharged, sandy soil in the ballast can be automatically separated, the ballast can be automatically put back to the parts between sleepers on the two sides of replaced sleepers, rammed and vibrated to be level, and the shape of a runway shoulder and the ballast bed can be restored; four nuts can be synchronously assembled or disassembled, the fatigue life of bolts can be prolonged, and the reliability of connection between the sleepers and the steel rail can be ensured; the integrated rail rotating and sleeper push-pull device is adopted, and the sleeper replacing machine is compact in structure, suitable for various sleeper replacing work of linear and curve rail sections and high in sleeper replacing efficiency.

Owner:JILIN UNIV

Tie renewal machine with series parallel four-rod mechanism

InactiveCN106351078AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemEngineering

The invention discloses a tie renewal machine with a series parallel four-rod mechanism, comprising a tamping and ballast leveling apparatus, a ballast shoulder and bed shaping apparatus, a grab destoning apparatus, a rock ballast collecting and discharging apparatus, a tie end destoning apparatus, a chain-tooth rock discharging apparatus, a four-nut synchronous handling apparatus, a first rail lifting apparatus, a tie transfer and sliding apparatus, a tie hoisting apparatus, a power generator, a hydraulic system and control system case and a track car. Working apparatuses can be aligned to working positions accurately; rock ballast is automatically discharged from between ties, outside of tie ends and the bed below a track, sandy soil in the rock ballast is automatically separated and is automatically applied back to fill the space between ties on two sides a renewed tie before being tamped, the shape of the ballast shoulder and bed is automatically restored; four nuts are handled in sync, fatigue life of a bolt is prolonged, and tie and track connection reliability is guaranteed; the tie transfer and sliding apparatus is an integrated apparatus with compact structure, adapting to various tie renewing workers at linear and curved rail sections, and tie renewing efficiency is improved.

Owner:JILIN UNIV

Mechanical-electrical-hydraulic integrated sleeper replacement device

InactiveCN106522046AQuickly align to working positionConsistent preloadRailway track constructionAutomatic controlControl system

The invention discloses a mechanical-electrical-hydraulic integrated sleeper replacement device. The mechanical-electrical-hydraulic integrated sleeper replacement device is composed of a four-nut synchronous assembly and disassembly device, a rail lifting device, a rail switching and sleeper sliding device, a sleeper hoisting device, an electric generator, a hydraulic system and control system cabinet and a rail vehicle, wherein the rail vehicle is provided with a plurality of trundles and two longitudinal beams; the four-nut synchronous assembly and disassembly device, the rail lifting device, the rail switching and sleeper sliding device, the sleeper hoisting device, the electric generator and the hydraulic system and control system cabinet are arranged on the two longitudinal beams of the rail vehicle; and the rail vehicle is dragged by an engineering vehicle. By means of the mechanical-electrical-hydraulic integrated sleeper replacement device, a working device can be aligned at the working position quickly; four nuts are assembled and disassembled synchronously, so that the pretightening forces of the four nuts are coincident, the fatigue life of bolts is prolonged, and connection reliability of a sleeper and a steel rail is ensured; the sleeper is quickly hoisted and arranged; the device is suitable for sleeper replacement of linear and curved rail sections; and the rail switching and sleeper sliding device is an integrated device, the structure is simple and compact, automatic control is achieved, operation is convenient, and efficiency of sleeper replacement work is high.

Owner:KUNMING UNIV

Small railway maintenance machine provided with sleeper end ballast clearing device

InactiveCN106283983AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a small railway maintenance machine provided with a sleeper end ballast clearing device. The small railway maintenance machine provided with the sleeper end ballast clearing device is composed of a tamping ballasting device, a runway shoulder and ballast bed shape repairing device, a clam bucket ballast clearing device, a ballast collecting and discharging device, the sleeper end ballast clearing device, a sprocket ballast discharging device, a four nut synchronous assembly and disassembly device, a first track lifting device, a retracking and sleeper push-pull device, a sleeper hoisting and swinging device, a rail car, a generator and a hydraulic system and control system box. According to the invention, the working devices can be aligned with the working positions quickly; ballast between sleepers, on the outer sides of sleeper ends and on a ballast bed below the rail is automatically discharged; sandy soil in the ballast is automatically separated, the ballast is automatically backfilled between sleepers on the both sides of the already-exchanged sleeper to be tamped and vibrated, and the shapes of the runway shoulder and the ballast bed are automatically repaired; four nuts are assembled and disassembled synchronously, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the rail is guaranteed; and the retracking and sleeper push-pull device is an integrated device, the structure is compact, various tasks of sleeper exchanging at straight and curved rail sections are adapted to, and the working efficiency of sleeper exchanging is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Sleeper changing machine with opposite crank track lifting device

InactiveCN106351090AQuickly align to working positionEasy dischargeBallastwayTrack superstructureElectricityControl system

The invention discloses a sleeper changing machine with an opposite crank track lifting device. The machine is composed of a tamping slag flattening device, a runway shoulder and track bed shaping device, a grab bucket stone removing device, a ballast collecting and discharging device, a sleeper end stone removing device, a sprocket stone discharging device, a four-nut synchronous assembling and disassembling device, a first track lifting device, a track transferring and sleeper pushing and pulling device, a sleeping lifting device, an electricity generator, a hydraulic system, a control system box and a track car. The working device can be rapidly aligned to the working position; ballast between sleepers, on the outer sides of the ends of the sleepers and the a ballast bed below a steel track are automatically discharged, sandy soil in ballast is automatically separated, the changed sleepers on the two sides are backfilled with the ballast automatically, tamping and vibrating flattening are performed, and the shapes of runway shoulders and ballast beds are automatically repaired; four-nut synchronous assembling and disassembling are achieved, the fatigue life of bolts is prolonged, and the connection reliability of the sleepers and the steel track is ensured; the sleeper transferring and sleeper pushing and pulling device is integrated, the structure is compact, the sleeper changing machine is suitable for various tasks of linear and curved track section sleeper changing, and the sleeper changing working efficiency is high.

Owner:KUNMING UNIV

Railway sleeper replacing machine with device capable of synchronously assembling and disassembling four nuts of railway sleepers

InactiveCN106381776AQuickly align to working positionEasy dischargeBallastwayTrack superstructureControl systemPush pull

The invention discloses a railway sleeper replacing machine with a device capable of synchronously assembling and disassembling four nuts of railway sleepers. The railway sleeper replacing machine comprises a tamping and ballast leveling device, a ballast shoulder and ballast bed shaping device, a grabbing bucket ballast cleaning device, a ballast collecting and discharging device, a sleeper end ballast cleaning device, a chain tooth ballast discharging device, a four-nut synchronously assembling and disassembling device, a rail lifting device, a rail-turning and railway sleeper pushing-pulling device, a railway sleeper lifting and transporting device, a power generator, a hydraulic system and control system box, and a rail car. The railway sleeper replacing machine is capable of rapidly enabling operating devices to be aligned to operating positions, automatically discharging the ballast between the railway sleepers, the outer sides of the sleeper ends and the ballast beds under steel rails, automatically separating sand soil in the ballast, automatically backfilling the ballast till tamping and leveling the railway sleepers on two sides of the replaced railway sleepers, automatically repairing the shape of ballast shoulders and ballast beds, synchronously assembling and disassembling four nuts, prolonging the fatigue life of bolts and ensuring reliability of connection between the railway sleepers and the steel rails; the rail-turning and railway sleeper pushing-pulling device is an integrated device; the railway sleeper replacing machine is compact in structure, is adapted to various operations of replacing sleepers of straight and curved rail road sections, and is high in sleeper-replacing operation efficiency.

Owner:HEBEI UNIV OF ENG

Mechanical-electrical-hydraulic integrated multifunctional railway maintenance machine

InactiveCN106223133AQuickly align to working positionEasy dischargeBallastwayRailway track constructionPush pullSprocket

The invention discloses a mechanical-electrical-hydraulic integrated multifunctional railway maintenance machine. The mechanical-electrical-hydraulic integrated multifunctional railway maintenance machine is composed of a tamping and ballast leveling device, a runway shoulder and ballast bed modification device, a grabbing bucket ballast cleaning device, a ballast collection and removal device, a sleeper end ballast cleaning device, a sprocket ballast discharging device, a four-nut synchronous assembling and disassembling device, a first rail lifting device, a shunting and push-pull sleeper device, a sleeper hoisting device, a power generator, a hydraulic system and control system box and a railcar. According to the mechanical-electrical-hydraulic integrated multifunctional railway maintenance machine, a working device can be rapidly aligned to a working position; ballast aggregates between sleepers, ballast aggregates of ballast beds at an outer side of a sleeper end and under steel rails are automatically discharged, and sandy soil in the ballast aggregates is automatically separated; the ballast aggregates are automatically backfilled between the sleepers at two sides of a changed sleeper and are tamped and flatly vibrated, and shapes of a runway shoulder and the ballast bed are automatically repaired; synchronous assembling and disassembling of four nuts are realized, and the fatigue life of a bolt is prolonged; the reliability of connecting the sleepers and the steel rails is guaranteed; a crossing sleeper and a push-pull sleeper are of an integrated device; the mechanical-electrical-hydraulic integrated multifunctional railway maintenance machine has a compact structure and is suitable for all work of changing the sleepers of straight-line and curve rail road sections, and the efficiency of sleeper changing work is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Sleeper changing machine provided with transversely-moving grab bucket stone-clearing device

InactiveCN106351091AQuickly align to working positionEasy dischargeBallastwayRailway track constructionControl systemEngineering

The invention discloses a sleeper changing machine provided with a transversely-moving grab bucket stone-clearing device. The sleeper changing machine consists of a tamping and ballast flattening device, a rail shoulder and rail bed reshaping device, the grab bucket stone-clearing device, a ballast collecting and discharging device, a sleeper end stone-clearing device, a chain tooth stone discharging device, a synchronous four-nut mounting and dismounting device, a rail lifting device, a rail turning and sleeper pushing and pulling device, a sleeper hoisting device, a generator, a hydraulic system and control system box and a rail car. The sleeper changing machine can rapidly align working devices to working positions, automatically discharges out ballast between sleepers, on the outer side of the sleeper ends and on a rail bed under steel rails, automatically separates sandy soil in the ballast, automatically backfills the ballast between the changed sleepers on two sides for tamping and ballast flattening, automatically repairs the shapes of rail shoulders and the rail bed, achieves synchronous four-nut mounting and dismounting, prolongs the service life of bolts, ensures the reliability of sleeper and steel rail connection, is compact in structure and high in sleeper changing work efficiency and adapts to various sleeper changing works of linear and curved rail sections, and the rail turning and sleeper pushing and pulling device is an integrated device.

Owner:KUNMING UNIV

Sleeper replacement machine with parallel four-bar mechanism

InactiveCN106522044AQuickly align to working positionEasy dischargeBallastwayRailway track constructionControl systemEngineering

The invention discloses a sleeper replacement machine with a parallel four-bar mechanism. The sleeper replacement machine is composed of a tamping and ballast leveling device, a rail shoulder and rail bed modification device, a grab bucket stone-removal device, a ballast concentrated discharging device, a sleeper end stone-removal device, a chain gear stone discharging device, a four-nut synchronous assembly and disassembly device, a rail lifting device, a rail switching and sleeper sliding device, a sleeper hoisting device, an electric generator, a hydraulic system and control system cabinet and a rail vehicle. The sleeper replacement machine can quickly make a working device be aligned with the working position, automatically discharge ballast between sleepers, on the outer side of the sleeper ends and on a rail bed below steel rails, automatically separate sandy soil from the ballast, automatically make the ballast backfill the portion between new sleepers on the two sides and be tamped and leveled, and automatically modify the shape of a rail shoulder and the rail bed; four nuts are assembled and disassembled synchronously, the fatigue life of bolts is prolonged, and connection reliability of the sleepers and the steel rails is ensured; and the rail switching and sleeper sliding device is an integrated device, and is compact in structure and suitable for various operations for sleeper replacement of linear and curved rail sections, and efficiency of sleeper replacement work is high.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Automatic sleeper replacing machine with pillow end stone picker

InactiveCN106337328AQuickly align to working positionEasy dischargeBallastwayTrack superstructurePush and pullControl system

The invention discloses an automatic sleeper replacing machine with a pillow end stone picker. The automatic sleeper replacing machine with the pillow end stone picker is formed by a tamping and ballasting device, a runway shoulder and ballast bed modification device, a grab bucket stone picker, a stone ballast collecting and discharging device, the pillow end stone picker, a sprocket stone discharging device, a four-nut synchronization assembling and disassembling device, a rail lifting device, a rail rotating and sleeper push-and-pull device, a sleeper hoisting and swinging device, an electric generator, a hydraulic system, a control system box and a rail car. According to the automatic sleeper replacing machine with the pillow end stone picker provided by the invention, each working device can quickly align to a working position; stone ballasts of ballast beds between sleepers, on the outer side of pillow ends, and under steel rails are automatically discharged, sandy soil in the stone ballasts are automatically separated, the stone ballasts are automatically backfilled between the sleepers on two sides of a replaced sleeper so as to be tamped and ballasted, and the shapes of runway shoulders and ballast beds are automatically modified; four nuts can be synchronously assembled and disassembled, so that the fatigue life of bolts is improved, and the connecting reliability of the sleepers and the steel rails is ensured; the rail rotating and sleeper push-and-pull device is an integrated device, which is compact in structure, adapt to various tasks of sleeper replacing in straight and curve rail sections, and is high in sleeper replacing efficiency.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com