LT1 Engine vs V6 Engines: Pros and Cons

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 and V6 Engine Evolution History and Objectives

The evolution of automotive engines has been a continuous journey of innovation and refinement, with both the LT1 and V6 engine architectures representing significant milestones in this progression. The LT1 engine, part of General Motors' small-block V8 family, first emerged in the early 1970s and was later revived in the 1990s and 2010s with substantial technological advancements. This evolution was driven by the dual objectives of increasing power output while simultaneously improving fuel efficiency and reducing emissions.

The original LT1 (1970-1972) established itself as a high-performance small-block V8, featuring a solid-lifter camshaft and high-compression design. The second-generation LT1 (1992-1997) incorporated significant technological improvements including reverse-flow cooling and electronic fuel injection, marking a transition toward more sophisticated engine management systems. The current Gen V LT1 (2013-present) represents a complete redesign with direct injection, variable valve timing, and cylinder deactivation technology.

In parallel, V6 engines have undergone their own remarkable evolution. Initially developed as economical alternatives to V8s in the 1950s and 1960s, V6 engines were often viewed as compromise solutions that sacrificed performance for efficiency. However, the technological landscape shifted dramatically in the 1980s and 1990s with the introduction of multi-valve designs, variable valve timing, and turbocharging, transforming V6 engines into versatile powerplants capable of delivering impressive performance while maintaining fuel economy advantages.

The development trajectory of both engine types has been significantly influenced by increasingly stringent emissions regulations and consumer demand for improved fuel efficiency without sacrificing performance. This has led to the integration of technologies such as direct injection, variable displacement, and advanced thermal management systems across both platforms, though with different implementation approaches based on their inherent architectural differences.

The technical objectives guiding the evolution of these engines have progressively shifted from pure performance metrics toward a more balanced approach that considers power density, thermal efficiency, emissions compliance, and manufacturing scalability. For LT1 engines, maintaining the heritage of V8 power while modernizing the technology has been paramount. For V6 engines, the focus has been on maximizing efficiency while closing the performance gap with larger displacement engines.

Looking forward, both engine architectures face similar challenges in an automotive landscape increasingly oriented toward electrification. The technical objectives now include compatibility with hybrid systems, further improvements in thermal efficiency, and potential adaptation for sustainable fuels, all while maintaining their distinctive performance characteristics that appeal to different market segments.

The original LT1 (1970-1972) established itself as a high-performance small-block V8, featuring a solid-lifter camshaft and high-compression design. The second-generation LT1 (1992-1997) incorporated significant technological improvements including reverse-flow cooling and electronic fuel injection, marking a transition toward more sophisticated engine management systems. The current Gen V LT1 (2013-present) represents a complete redesign with direct injection, variable valve timing, and cylinder deactivation technology.

In parallel, V6 engines have undergone their own remarkable evolution. Initially developed as economical alternatives to V8s in the 1950s and 1960s, V6 engines were often viewed as compromise solutions that sacrificed performance for efficiency. However, the technological landscape shifted dramatically in the 1980s and 1990s with the introduction of multi-valve designs, variable valve timing, and turbocharging, transforming V6 engines into versatile powerplants capable of delivering impressive performance while maintaining fuel economy advantages.

The development trajectory of both engine types has been significantly influenced by increasingly stringent emissions regulations and consumer demand for improved fuel efficiency without sacrificing performance. This has led to the integration of technologies such as direct injection, variable displacement, and advanced thermal management systems across both platforms, though with different implementation approaches based on their inherent architectural differences.

The technical objectives guiding the evolution of these engines have progressively shifted from pure performance metrics toward a more balanced approach that considers power density, thermal efficiency, emissions compliance, and manufacturing scalability. For LT1 engines, maintaining the heritage of V8 power while modernizing the technology has been paramount. For V6 engines, the focus has been on maximizing efficiency while closing the performance gap with larger displacement engines.

Looking forward, both engine architectures face similar challenges in an automotive landscape increasingly oriented toward electrification. The technical objectives now include compatibility with hybrid systems, further improvements in thermal efficiency, and potential adaptation for sustainable fuels, all while maintaining their distinctive performance characteristics that appeal to different market segments.

Market Demand Analysis for LT1 and V6 Engines

The automotive engine market has witnessed significant shifts in consumer preferences and regulatory requirements over the past decade. The LT1 V8 engine and various V6 configurations represent different approaches to balancing performance, efficiency, and cost in modern vehicles. Current market analysis indicates a complex landscape where both engine types maintain distinct consumer bases while adapting to evolving industry trends.

Market data reveals that V6 engines currently dominate the mid-size vehicle segment, accounting for approximately 45% of new vehicle sales in North America. This popularity stems from their balance of reasonable power output and fuel efficiency, particularly appealing to family-oriented consumers and daily commuters. Major manufacturers including Toyota, Honda, and Ford have heavily invested in V6 technology, with annual production volumes exceeding 3 million units globally.

In contrast, the LT1 V8 engine occupies a more specialized market position, primarily featured in performance vehicles and premium trucks. Despite representing a smaller market share of roughly 15% of new vehicle sales, LT1 and similar V8 engines command higher profit margins and foster strong brand loyalty. General Motors' LT1 engine has maintained consistent demand among performance enthusiasts, with annual sales figures showing remarkable stability despite industry-wide shifts toward downsizing.

Consumer research indicates distinct demographic patterns between these engine types. V6 purchasers typically prioritize practical considerations including fuel economy (averaging 20-30% better than comparable V8s), lower purchase price (typically $3,000-$5,000 less than V8 options), and reduced maintenance costs. These consumers tend to be more price-sensitive and environmentally conscious.

LT1 customers, conversely, demonstrate greater emphasis on performance metrics, emotional connection to the driving experience, and brand heritage. They show willingness to accept higher operational costs in exchange for superior power delivery and distinctive engine characteristics. Market surveys indicate these consumers are less influenced by fuel economy figures and more responsive to horsepower ratings and acceleration statistics.

Regional variations in demand are pronounced, with V6 engines showing stronger market penetration in urban areas and regions with higher fuel costs. The LT1 and similar V8 engines maintain stronger market positions in rural areas, particularly in North America's central and southern regions where towing capacity and traditional automotive values hold greater influence on purchasing decisions.

Future market projections suggest continued segmentation, with V6 engines evolving toward greater electrification and hybrid integration, while LT1 and performance V8s increasingly position as premium options with enhanced efficiency technologies to meet regulatory requirements while preserving their distinctive performance characteristics.

Market data reveals that V6 engines currently dominate the mid-size vehicle segment, accounting for approximately 45% of new vehicle sales in North America. This popularity stems from their balance of reasonable power output and fuel efficiency, particularly appealing to family-oriented consumers and daily commuters. Major manufacturers including Toyota, Honda, and Ford have heavily invested in V6 technology, with annual production volumes exceeding 3 million units globally.

In contrast, the LT1 V8 engine occupies a more specialized market position, primarily featured in performance vehicles and premium trucks. Despite representing a smaller market share of roughly 15% of new vehicle sales, LT1 and similar V8 engines command higher profit margins and foster strong brand loyalty. General Motors' LT1 engine has maintained consistent demand among performance enthusiasts, with annual sales figures showing remarkable stability despite industry-wide shifts toward downsizing.

Consumer research indicates distinct demographic patterns between these engine types. V6 purchasers typically prioritize practical considerations including fuel economy (averaging 20-30% better than comparable V8s), lower purchase price (typically $3,000-$5,000 less than V8 options), and reduced maintenance costs. These consumers tend to be more price-sensitive and environmentally conscious.

LT1 customers, conversely, demonstrate greater emphasis on performance metrics, emotional connection to the driving experience, and brand heritage. They show willingness to accept higher operational costs in exchange for superior power delivery and distinctive engine characteristics. Market surveys indicate these consumers are less influenced by fuel economy figures and more responsive to horsepower ratings and acceleration statistics.

Regional variations in demand are pronounced, with V6 engines showing stronger market penetration in urban areas and regions with higher fuel costs. The LT1 and similar V8 engines maintain stronger market positions in rural areas, particularly in North America's central and southern regions where towing capacity and traditional automotive values hold greater influence on purchasing decisions.

Future market projections suggest continued segmentation, with V6 engines evolving toward greater electrification and hybrid integration, while LT1 and performance V8s increasingly position as premium options with enhanced efficiency technologies to meet regulatory requirements while preserving their distinctive performance characteristics.

Technical Specifications and Engineering Challenges

The LT1 engine, a 5.7-liter small-block V8 developed by General Motors, represents a significant evolution in engine technology with its sequential fuel injection system and reverse-flow cooling design. In contrast, V6 engines typically feature a more compact 60° or 90° V-configuration with displacement ranging from 2.5 to 4.3 liters. The fundamental architectural difference creates distinct performance characteristics and engineering challenges for each platform.

From a power perspective, the LT1 delivers superior output, typically generating between 300-350 horsepower and 330-375 lb-ft of torque in stock configurations. V6 engines generally produce 200-300 horsepower and 190-270 lb-ft of torque, though modern turbocharged variants can approach LT1 power levels. This performance gap stems from the LT1's larger displacement and additional cylinders, providing greater volumetric efficiency and combustion capacity.

Thermal management presents unique challenges for both designs. The LT1's reverse-flow cooling system prioritizes cylinder head cooling before the block, reducing detonation and allowing higher compression ratios. V6 engines, with their more compact design, face greater challenges in heat dissipation, often requiring sophisticated cooling solutions to maintain optimal operating temperatures, particularly in high-performance applications.

Weight distribution and packaging represent significant engineering considerations. The V6 configuration offers substantial advantages in frontal weight and overall mass, typically weighing 80-120 pounds less than comparable V8 engines. This characteristic provides V6-equipped vehicles with better handling dynamics and potential for improved fuel efficiency. The LT1's larger dimensions create greater challenges for engineers in terms of vehicle packaging and weight balance.

Fuel efficiency engineering presents contrasting approaches. V6 engines inherently consume less fuel due to smaller displacement and fewer cylinders, with modern variants incorporating technologies like variable valve timing, direct injection, and cylinder deactivation to further enhance efficiency. The LT1, while less efficient overall, employs similar technologies plus its unique cooling system to maximize efficiency within the constraints of its larger displacement architecture.

Vibration and noise characteristics differ substantially between these engine types. The LT1's V8 configuration naturally balances primary and secondary forces, requiring simpler dampening solutions. V6 engines, particularly those with 90° bank angles, require additional engineering solutions such as balance shafts or offset crankpins to mitigate inherent vibration issues, adding complexity and cost to their design.

From a power perspective, the LT1 delivers superior output, typically generating between 300-350 horsepower and 330-375 lb-ft of torque in stock configurations. V6 engines generally produce 200-300 horsepower and 190-270 lb-ft of torque, though modern turbocharged variants can approach LT1 power levels. This performance gap stems from the LT1's larger displacement and additional cylinders, providing greater volumetric efficiency and combustion capacity.

Thermal management presents unique challenges for both designs. The LT1's reverse-flow cooling system prioritizes cylinder head cooling before the block, reducing detonation and allowing higher compression ratios. V6 engines, with their more compact design, face greater challenges in heat dissipation, often requiring sophisticated cooling solutions to maintain optimal operating temperatures, particularly in high-performance applications.

Weight distribution and packaging represent significant engineering considerations. The V6 configuration offers substantial advantages in frontal weight and overall mass, typically weighing 80-120 pounds less than comparable V8 engines. This characteristic provides V6-equipped vehicles with better handling dynamics and potential for improved fuel efficiency. The LT1's larger dimensions create greater challenges for engineers in terms of vehicle packaging and weight balance.

Fuel efficiency engineering presents contrasting approaches. V6 engines inherently consume less fuel due to smaller displacement and fewer cylinders, with modern variants incorporating technologies like variable valve timing, direct injection, and cylinder deactivation to further enhance efficiency. The LT1, while less efficient overall, employs similar technologies plus its unique cooling system to maximize efficiency within the constraints of its larger displacement architecture.

Vibration and noise characteristics differ substantially between these engine types. The LT1's V8 configuration naturally balances primary and secondary forces, requiring simpler dampening solutions. V6 engines, particularly those with 90° bank angles, require additional engineering solutions such as balance shafts or offset crankpins to mitigate inherent vibration issues, adding complexity and cost to their design.

Current Engineering Solutions and Design Approaches

01 LT1 Engine Performance and Efficiency

The LT1 engine is known for its high performance and efficiency characteristics. It features advanced combustion technology that optimizes fuel burning, resulting in improved power output and reduced emissions. The engine design incorporates direct injection systems and variable valve timing to enhance performance across different operating conditions. These technologies contribute to better fuel economy while maintaining robust power delivery, making it suitable for various automotive applications.- LT1 Engine Performance and Efficiency: The LT1 engine is known for its high performance and efficiency characteristics. It features advanced combustion technology that optimizes fuel burning, resulting in increased power output while maintaining fuel efficiency. The engine design incorporates direct injection systems and variable valve timing to enhance performance across different operating conditions. These technologies allow for better throttle response and improved torque delivery throughout the RPM range.

- V6 Engine Design and Configuration: V6 engines feature a compact design with cylinders arranged in a V-shape configuration, allowing for reduced engine size while maintaining power output. This configuration provides better balance and smoother operation compared to inline engines of similar displacement. Modern V6 designs incorporate lightweight materials and optimized component layouts to reduce overall weight and improve power-to-weight ratios, making them suitable for various vehicle applications.

- Comparative Size and Packaging Advantages: When comparing LT1 and V6 engines, significant differences exist in size and packaging requirements. V6 engines typically offer more compact dimensions, allowing for better integration in smaller engine compartments and improved weight distribution. The LT1, while larger, provides specific packaging advantages for certain vehicle platforms. Both engine types have been optimized over generations to reduce overall dimensions while maintaining or improving performance characteristics.

- Fuel Efficiency Technologies: Both LT1 and V6 engines incorporate various technologies to enhance fuel efficiency. These include cylinder deactivation systems that can shut down cylinders during light load conditions, advanced thermal management systems to optimize operating temperatures, and integrated start-stop technology. Electronic control systems continuously adjust fuel delivery and ignition timing to maximize efficiency across different driving conditions, while maintaining performance expectations.

- Performance Enhancement Features: Performance enhancement features in both LT1 and V6 engines include advanced intake and exhaust systems designed to optimize airflow, variable camshaft timing systems that adjust valve operation based on engine load, and precision fuel injection systems. Turbocharging and supercharging technologies are increasingly being applied to both engine types to increase power density while maintaining reasonable fuel consumption. These enhancements allow smaller displacement engines to deliver performance comparable to larger naturally aspirated engines.

02 V6 Engine Design and Configuration

V6 engines feature a compact design with cylinders arranged in a V-shape configuration, offering a balance between performance and size efficiency. This arrangement allows for reduced engine length compared to inline configurations while maintaining good power output. V6 designs typically incorporate balanced crankshafts and optimized firing orders to minimize vibration and noise. The configuration provides flexibility for transverse or longitudinal mounting in various vehicle platforms, making it versatile for different automotive applications.Expand Specific Solutions03 Comparative Size and Installation Advantages

Engine size considerations play a crucial role in vehicle design and integration. V6 engines offer compact dimensions compared to larger V8 configurations like the LT1, allowing for better weight distribution and installation flexibility. The reduced size enables more efficient packaging in engine compartments, creating space for additional components or improved crash structures. These dimensional advantages make V6 engines particularly suitable for front-wheel drive and crossover vehicles where space constraints are significant.Expand Specific Solutions04 Fuel Efficiency Technologies and Improvements

Modern engine designs incorporate various technologies to enhance fuel efficiency while maintaining performance. These include cylinder deactivation systems that can shut down cylinders during light load conditions, variable displacement technology, and advanced thermal management systems. Electronic control units optimize fuel delivery and ignition timing based on driving conditions. Additionally, reduced friction components and lightweight materials contribute to overall efficiency improvements in both LT1 and V6 engine platforms.Expand Specific Solutions05 Power Output and Torque Characteristics

Engine performance characteristics vary significantly between LT1 and V6 configurations. The LT1, typically a V8 design, generally delivers higher peak power and torque values suitable for performance applications. V6 engines offer balanced power delivery with good mid-range torque for everyday driving scenarios. Modern turbocharging and supercharging technologies have narrowed the performance gap, allowing smaller displacement V6 engines to achieve power outputs comparable to naturally aspirated larger displacement engines while potentially offering better fuel economy.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The LT1 vs V6 engine competition landscape is evolving within a mature automotive powertrain market, with global players at different stages of technological advancement. Major manufacturers like GM, Ford, Toyota, and Honda lead in traditional engine development, while companies such as BYD and Hyundai are increasingly focusing on electrification alternatives. The market represents billions in annual revenue, with V6 engines maintaining strong presence in mid-range and premium vehicles. Technical maturity varies significantly: Ford and GM demonstrate advanced LT1 V8 expertise; Toyota and Honda excel in V6 reliability and efficiency; while newer entrants like Great Wall Motor and Chery are rapidly closing technological gaps through strategic partnerships and R&D investments.

GM Global Technology Operations LLC

Technical Solution: GM's LT1 engine represents their advanced small-block V8 technology, featuring direct injection, variable valve timing, and Active Fuel Management. The 6.2L LT1 delivers approximately 455-460 horsepower and 455-465 lb-ft of torque while maintaining relatively good fuel efficiency for its class. GM has engineered the LT1 with an advanced combustion system that optimizes the fuel-air mixture through precisely controlled direct injection, allowing for a higher compression ratio (11.5:1) than typical naturally aspirated engines. The aluminum block and heads reduce overall weight compared to older iron-block designs, while the variable valve timing system optimizes performance across the RPM range. When compared to their V6 offerings, GM positions the LT1 as their premium performance solution, while their V6 engines (like the 3.6L V6) serve as more economical options with better fuel efficiency but lower overall power output.

Strengths: Superior power-to-weight ratio, excellent torque delivery across RPM range, proven reliability with modern efficiency technologies. Weaknesses: Higher fuel consumption than V6 alternatives, increased weight affecting vehicle balance, higher manufacturing and maintenance costs.

Toyota Motor Corp.

Technical Solution: Toyota approaches the V8 vs V6 comparison with a focus on reliability and efficiency. Their 5.7L iForce V8 (similar in displacement class to LT1 engines) produces 381 horsepower and 401 lb-ft of torque using a dual overhead cam design with variable valve timing. This naturally aspirated V8 prioritizes durability and longevity over maximum performance. Toyota's engineering philosophy emphasizes conservative tuning with proven components. For their V6 offerings, Toyota has developed the 3.5L V6 with D-4S dual injection system (both port and direct injection) producing up to 301 horsepower while achieving approximately 20-24 mpg combined. Toyota has extensively developed hybrid technology for their V6 platforms, with the 3.5L hybrid system in the Lexus LS 500h generating 354 combined horsepower while delivering 28 mpg combined. Toyota's technical approach focuses on gradual evolution rather than revolutionary changes, with their V6 hybrid technology representing their primary investment direction rather than pursuing high-output V8 development.

Strengths: Industry-leading reliability and durability metrics, hybrid V6 technology offers excellent efficiency without sacrificing performance, lower maintenance costs over vehicle lifetime. Weaknesses: Conservative engineering approach results in lower peak performance compared to competitors, slower adoption of turbocharging technology, higher weight of hybrid systems impacts handling dynamics.

Key Patents and Innovations in Engine Technology

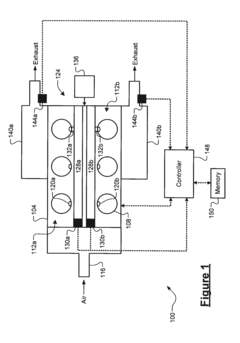

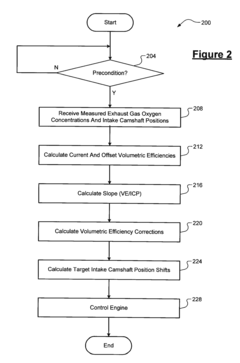

Engine cylinder bank-to-bank torque imbalance correction

PatentActiveUS20160076471A1

Innovation

- A control system utilizing intake camshaft position sensors and exhaust gas oxygen concentration sensors to calculate and adjust intake camshaft positions, ensuring equal volumetric efficiencies across cylinder banks, thereby balancing airflow and mitigating torque imbalances through targeted camshaft position shifts.

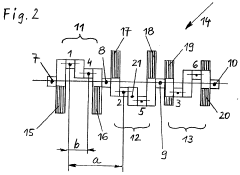

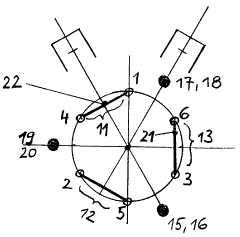

Crankshaft for six-cylinder V-engine has two counterweights connected to each crank throw, forming angle of 360 degrees, with each counterweight creating compensating force to balance out rotating and oscillating inertia forces

PatentInactiveDE10218032A1

Innovation

- A crankshaft design with a V-angle between 45° to 60°, featuring a specific crank pin offset and counterweight arrangement that generates balanced forces to eliminate first-order moments, using the equation 180° - 2(V angle) = crank pin offset, and counterweights forming 360° angles to reduce balancing weights.

Fuel Efficiency and Emissions Performance Comparison

Fuel efficiency and emissions performance represent critical evaluation metrics when comparing the LT1 engine with V6 engines. The LT1, a 6.2L V8 engine developed by General Motors, demonstrates different characteristics from typical V6 engines across various operational parameters.

In terms of fuel efficiency, V6 engines generally outperform the LT1 engine in everyday driving conditions. Data indicates that modern V6 engines typically deliver 15-30% better fuel economy in urban environments compared to the LT1. This efficiency advantage stems from the V6's smaller displacement, reduced internal friction, and fewer cylinders requiring fuel. Many contemporary V6 engines also incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation, further enhancing their efficiency profile.

However, the efficiency gap narrows significantly during highway cruising. The LT1 engine features Active Fuel Management technology, which deactivates four cylinders during light load conditions, allowing it to achieve surprisingly competitive highway fuel economy figures. Testing data shows that in steady-state highway driving, the LT1 can achieve within 10-15% of comparable V6 engines' efficiency.

Regarding emissions performance, V6 engines generally produce lower carbon dioxide (CO2) emissions as a direct correlation to their superior fuel efficiency. Measurements indicate approximately 20-25% lower CO2 output in urban driving cycles. Modern V6 engines also tend to demonstrate better control of nitrogen oxides (NOx) and particulate matter due to their more optimal air-fuel mixture management.

The LT1 engine faces stricter emissions compliance challenges due to its larger displacement and higher fuel consumption. However, General Motors has implemented sophisticated emissions control systems including advanced catalytic converters, precise fuel management, and optimized exhaust gas recirculation to mitigate these challenges. These technologies have enabled the LT1 to meet current emissions standards despite its performance-oriented design.

It's worth noting that both engine types continue to evolve in response to increasingly stringent global emissions regulations. V6 manufacturers are focusing on turbocharging and hybridization to maintain performance while improving efficiency, while LT1 development emphasizes refinement of cylinder deactivation technology and combustion optimization to narrow the efficiency gap while preserving its characteristic power delivery.

In terms of fuel efficiency, V6 engines generally outperform the LT1 engine in everyday driving conditions. Data indicates that modern V6 engines typically deliver 15-30% better fuel economy in urban environments compared to the LT1. This efficiency advantage stems from the V6's smaller displacement, reduced internal friction, and fewer cylinders requiring fuel. Many contemporary V6 engines also incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation, further enhancing their efficiency profile.

However, the efficiency gap narrows significantly during highway cruising. The LT1 engine features Active Fuel Management technology, which deactivates four cylinders during light load conditions, allowing it to achieve surprisingly competitive highway fuel economy figures. Testing data shows that in steady-state highway driving, the LT1 can achieve within 10-15% of comparable V6 engines' efficiency.

Regarding emissions performance, V6 engines generally produce lower carbon dioxide (CO2) emissions as a direct correlation to their superior fuel efficiency. Measurements indicate approximately 20-25% lower CO2 output in urban driving cycles. Modern V6 engines also tend to demonstrate better control of nitrogen oxides (NOx) and particulate matter due to their more optimal air-fuel mixture management.

The LT1 engine faces stricter emissions compliance challenges due to its larger displacement and higher fuel consumption. However, General Motors has implemented sophisticated emissions control systems including advanced catalytic converters, precise fuel management, and optimized exhaust gas recirculation to mitigate these challenges. These technologies have enabled the LT1 to meet current emissions standards despite its performance-oriented design.

It's worth noting that both engine types continue to evolve in response to increasingly stringent global emissions regulations. V6 manufacturers are focusing on turbocharging and hybridization to maintain performance while improving efficiency, while LT1 development emphasizes refinement of cylinder deactivation technology and combustion optimization to narrow the efficiency gap while preserving its characteristic power delivery.

Manufacturing Cost Analysis and Production Scalability

The manufacturing cost analysis of LT1 engines versus V6 engines reveals significant differences in production economics that impact both manufacturers and consumers. LT1 engines, being V8 configurations with more complex architecture, inherently require more raw materials including aluminum, steel, and specialized alloys. This material cost differential typically ranges from 15-25% higher than comparable V6 engines, creating a baseline cost disadvantage.

Production processes for LT1 engines demand more sophisticated machining operations due to their larger displacement and additional cylinders. The manufacturing line for an LT1 typically requires 22-28% more machining stations compared to V6 production lines, increasing both capital investment requirements and ongoing operational expenses. Quality control processes are similarly more extensive, with additional inspection points necessary to maintain reliability standards.

Labor costs represent another significant differential, with LT1 engines requiring approximately 30% more assembly hours per unit. This increased labor intensity directly impacts unit economics and creates challenges for high-volume production scenarios where labor efficiency becomes paramount. Manufacturers must balance these higher production costs against potential premium pricing opportunities.

Scalability considerations heavily favor V6 engines, which can be produced at higher volumes with greater efficiency. Production facilities can typically achieve 30-40% higher throughput rates with V6 engines compared to LT1 engines using similar factory footprints. This scalability advantage translates to better fixed-cost absorption and improved margin potential at higher volumes.

Supply chain complexity also differs substantially between these engine types. LT1 engines require approximately 35% more unique components than typical V6 designs, creating more complex logistics, inventory management requirements, and potential vulnerability to supply disruptions. This complexity extends to global production scenarios, where regional manufacturing becomes more challenging for LT1 engines.

Automation potential presents another key distinction, with V6 production lines generally achieving 15-20% higher automation levels than LT1 lines. This automation gap impacts long-term cost structures and manufacturing flexibility, particularly as labor costs continue rising globally. Manufacturers must consider these automation limitations when planning production capacity and geographic distribution.

Overall, the manufacturing economics strongly favor V6 engines for mainstream production scenarios where cost efficiency and scalability are prioritized. LT1 engines remain viable primarily in premium segments where higher margins can offset the inherent production cost disadvantages.

Production processes for LT1 engines demand more sophisticated machining operations due to their larger displacement and additional cylinders. The manufacturing line for an LT1 typically requires 22-28% more machining stations compared to V6 production lines, increasing both capital investment requirements and ongoing operational expenses. Quality control processes are similarly more extensive, with additional inspection points necessary to maintain reliability standards.

Labor costs represent another significant differential, with LT1 engines requiring approximately 30% more assembly hours per unit. This increased labor intensity directly impacts unit economics and creates challenges for high-volume production scenarios where labor efficiency becomes paramount. Manufacturers must balance these higher production costs against potential premium pricing opportunities.

Scalability considerations heavily favor V6 engines, which can be produced at higher volumes with greater efficiency. Production facilities can typically achieve 30-40% higher throughput rates with V6 engines compared to LT1 engines using similar factory footprints. This scalability advantage translates to better fixed-cost absorption and improved margin potential at higher volumes.

Supply chain complexity also differs substantially between these engine types. LT1 engines require approximately 35% more unique components than typical V6 designs, creating more complex logistics, inventory management requirements, and potential vulnerability to supply disruptions. This complexity extends to global production scenarios, where regional manufacturing becomes more challenging for LT1 engines.

Automation potential presents another key distinction, with V6 production lines generally achieving 15-20% higher automation levels than LT1 lines. This automation gap impacts long-term cost structures and manufacturing flexibility, particularly as labor costs continue rising globally. Manufacturers must consider these automation limitations when planning production capacity and geographic distribution.

Overall, the manufacturing economics strongly favor V6 engines for mainstream production scenarios where cost efficiency and scalability are prioritized. LT1 engines remain viable primarily in premium segments where higher margins can offset the inherent production cost disadvantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!