LT1 Engine Signal Detection Methods Explained

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Signal Detection Background and Objectives

The LT1 engine, introduced by General Motors in the early 1990s as part of the Generation II small-block V8 family, represented a significant technological advancement in engine management systems. This engine incorporated sophisticated electronic control systems that marked a departure from traditional mechanical control methods. The evolution of signal detection in automotive engines has progressed from rudimentary mechanical systems to complex electronic control units (ECUs) capable of processing multiple sensor inputs simultaneously.

Signal detection in the LT1 engine encompasses various parameters including crankshaft position, camshaft position, knock detection, oxygen levels, temperature measurements, and throttle position. These signals form the foundation of the engine management system, enabling precise control of fuel injection, ignition timing, and emissions management. The technological trajectory has been characterized by increasing precision, reliability, and integration of sensor networks.

The primary objective of LT1 engine signal detection research is to enhance engine performance while maintaining optimal fuel efficiency and minimizing emissions. This involves developing more accurate sensor technologies, improving signal processing algorithms, and implementing robust noise filtering techniques. Additionally, research aims to address the challenges of signal degradation under extreme operating conditions and the detection of subtle anomalies that may indicate potential system failures.

Historical development of engine signal detection technology shows a clear progression from analog to digital systems, with significant advancements in microprocessor capabilities enabling more sophisticated control strategies. The LT1's Opti-Spark distributor system, which utilized optical sensors for ignition timing, represented an innovative approach to signal detection that influenced subsequent engine designs.

Current technological trends point toward increased integration of machine learning algorithms for predictive diagnostics and adaptive control strategies. These developments aim to create self-optimizing engine management systems capable of adjusting to changing environmental conditions and driver behaviors. The industry is also moving toward higher sampling rates and greater signal resolution to capture transient phenomena that were previously undetectable.

The global push for reduced emissions and improved fuel economy has accelerated research into more precise signal detection methods. This includes the development of wide-band oxygen sensors, direct cylinder pressure monitoring, and ionization current sensing for combustion quality assessment. These technologies enable more precise control of the combustion process, resulting in cleaner and more efficient engine operation.

Understanding the technical foundations and evolutionary path of LT1 engine signal detection methods provides crucial context for evaluating current technologies and identifying promising research directions. This knowledge serves as the cornerstone for developing next-generation engine management systems that will meet increasingly stringent performance and environmental requirements.

Signal detection in the LT1 engine encompasses various parameters including crankshaft position, camshaft position, knock detection, oxygen levels, temperature measurements, and throttle position. These signals form the foundation of the engine management system, enabling precise control of fuel injection, ignition timing, and emissions management. The technological trajectory has been characterized by increasing precision, reliability, and integration of sensor networks.

The primary objective of LT1 engine signal detection research is to enhance engine performance while maintaining optimal fuel efficiency and minimizing emissions. This involves developing more accurate sensor technologies, improving signal processing algorithms, and implementing robust noise filtering techniques. Additionally, research aims to address the challenges of signal degradation under extreme operating conditions and the detection of subtle anomalies that may indicate potential system failures.

Historical development of engine signal detection technology shows a clear progression from analog to digital systems, with significant advancements in microprocessor capabilities enabling more sophisticated control strategies. The LT1's Opti-Spark distributor system, which utilized optical sensors for ignition timing, represented an innovative approach to signal detection that influenced subsequent engine designs.

Current technological trends point toward increased integration of machine learning algorithms for predictive diagnostics and adaptive control strategies. These developments aim to create self-optimizing engine management systems capable of adjusting to changing environmental conditions and driver behaviors. The industry is also moving toward higher sampling rates and greater signal resolution to capture transient phenomena that were previously undetectable.

The global push for reduced emissions and improved fuel economy has accelerated research into more precise signal detection methods. This includes the development of wide-band oxygen sensors, direct cylinder pressure monitoring, and ionization current sensing for combustion quality assessment. These technologies enable more precise control of the combustion process, resulting in cleaner and more efficient engine operation.

Understanding the technical foundations and evolutionary path of LT1 engine signal detection methods provides crucial context for evaluating current technologies and identifying promising research directions. This knowledge serves as the cornerstone for developing next-generation engine management systems that will meet increasingly stringent performance and environmental requirements.

Market Analysis for LT1 Engine Signal Detection Systems

The global market for LT1 engine signal detection systems has experienced significant growth over the past decade, driven by increasing demand for high-performance engine management solutions in both OEM and aftermarket segments. Current market valuations indicate the automotive engine management systems market exceeds $80 billion globally, with signal detection technologies representing approximately 15% of this segment.

The North American market remains the largest consumer of LT1 engine signal detection systems, accounting for nearly 40% of global demand. This dominance stems from the strong presence of performance vehicle manufacturing and a robust aftermarket modification culture. Europe follows with approximately 30% market share, while Asia-Pacific represents the fastest-growing region with annual growth rates exceeding 8%.

Consumer demand patterns reveal a clear shift toward more sophisticated signal detection systems that offer enhanced precision, reliability, and diagnostic capabilities. End-users increasingly prioritize systems that provide real-time data analysis and predictive maintenance features, with over 70% of professional mechanics and performance enthusiasts citing these capabilities as critical purchasing factors.

Market segmentation analysis shows three distinct customer categories: OEM manufacturers (35%), professional automotive service providers (40%), and performance enthusiasts/DIY market (25%). Each segment demonstrates unique purchasing behaviors and technical requirements, with OEMs focusing on integration capabilities, service providers on diagnostic functionality, and enthusiasts on customization options.

Competitive pricing analysis indicates a wide range of price points, from entry-level systems starting around $200 to professional-grade solutions exceeding $2,000. The mid-range segment ($500-$1,000) has shown the strongest growth, suggesting a market sweet spot balancing performance and affordability.

Distribution channels have evolved significantly, with online sales now accounting for over 45% of total market volume. Traditional brick-and-mortar automotive parts retailers maintain approximately 30% market share, while direct OEM channels represent the remaining 25%. The online channel continues to grow at twice the rate of physical retail, reflecting broader e-commerce trends in automotive components.

Market forecasts project continued growth at a compound annual rate of 6.5% through 2028, with particularly strong expansion in wireless and cloud-connected signal detection systems. Emerging markets in Southeast Asia and Latin America present significant growth opportunities, with potential to reshape regional market distribution over the next five years.

The North American market remains the largest consumer of LT1 engine signal detection systems, accounting for nearly 40% of global demand. This dominance stems from the strong presence of performance vehicle manufacturing and a robust aftermarket modification culture. Europe follows with approximately 30% market share, while Asia-Pacific represents the fastest-growing region with annual growth rates exceeding 8%.

Consumer demand patterns reveal a clear shift toward more sophisticated signal detection systems that offer enhanced precision, reliability, and diagnostic capabilities. End-users increasingly prioritize systems that provide real-time data analysis and predictive maintenance features, with over 70% of professional mechanics and performance enthusiasts citing these capabilities as critical purchasing factors.

Market segmentation analysis shows three distinct customer categories: OEM manufacturers (35%), professional automotive service providers (40%), and performance enthusiasts/DIY market (25%). Each segment demonstrates unique purchasing behaviors and technical requirements, with OEMs focusing on integration capabilities, service providers on diagnostic functionality, and enthusiasts on customization options.

Competitive pricing analysis indicates a wide range of price points, from entry-level systems starting around $200 to professional-grade solutions exceeding $2,000. The mid-range segment ($500-$1,000) has shown the strongest growth, suggesting a market sweet spot balancing performance and affordability.

Distribution channels have evolved significantly, with online sales now accounting for over 45% of total market volume. Traditional brick-and-mortar automotive parts retailers maintain approximately 30% market share, while direct OEM channels represent the remaining 25%. The online channel continues to grow at twice the rate of physical retail, reflecting broader e-commerce trends in automotive components.

Market forecasts project continued growth at a compound annual rate of 6.5% through 2028, with particularly strong expansion in wireless and cloud-connected signal detection systems. Emerging markets in Southeast Asia and Latin America present significant growth opportunities, with potential to reshape regional market distribution over the next five years.

Current Challenges in Engine Signal Detection Technology

Despite significant advancements in engine signal detection technology, the LT1 engine monitoring systems face several persistent challenges that impede optimal performance and reliability. Signal noise remains a primary concern, particularly in high-vibration environments where electromagnetic interference from adjacent vehicle systems can corrupt critical sensor data. This noise-to-signal ratio problem becomes especially pronounced during transient operating conditions, making accurate real-time analysis difficult.

Resolution limitations present another significant hurdle. Current sensor technologies struggle to detect subtle changes in engine parameters that may indicate early-stage failures or performance degradation. The sampling rates of conventional systems often prove inadequate for capturing microsecond-level events critical to comprehensive engine health monitoring, especially in high-performance LT1 applications.

Data processing bottlenecks further complicate signal detection efficacy. The sheer volume of data generated by modern engine management systems can overwhelm processing capabilities, leading to latency issues that compromise the timeliness of diagnostic responses. This challenge is exacerbated by the increasing complexity of engine control algorithms that require more sophisticated signal processing techniques.

Sensor degradation represents a persistent reliability issue. Environmental factors such as extreme temperatures, chemical exposure, and vibration accelerate sensor wear, causing drift in calibration accuracy over time. This degradation often goes undetected until significant measurement errors occur, potentially leading to misdiagnosis of engine conditions.

Integration complexity across different monitoring subsystems creates compatibility challenges. The LT1 engine's various control modules often employ proprietary communication protocols, complicating efforts to establish a unified signal detection framework. This fragmentation results in redundant sensors and inefficient data utilization across the engine management ecosystem.

Cost constraints continue to limit widespread adoption of advanced signal detection technologies. While high-precision sensors and sophisticated processing algorithms exist, their implementation costs remain prohibitive for mass-market applications, forcing compromises in detection capabilities.

Calibration complexity presents ongoing challenges for technicians and engineers. The interdependence of multiple signal parameters requires sophisticated calibration procedures that demand specialized expertise and equipment, increasing maintenance overhead and potential for misconfiguration.

Human-machine interface limitations also impact signal interpretation effectiveness. Current visualization tools often fail to present complex signal data in intuitive formats, making it difficult for technicians to quickly identify anomalies or patterns indicative of specific engine conditions.

Resolution limitations present another significant hurdle. Current sensor technologies struggle to detect subtle changes in engine parameters that may indicate early-stage failures or performance degradation. The sampling rates of conventional systems often prove inadequate for capturing microsecond-level events critical to comprehensive engine health monitoring, especially in high-performance LT1 applications.

Data processing bottlenecks further complicate signal detection efficacy. The sheer volume of data generated by modern engine management systems can overwhelm processing capabilities, leading to latency issues that compromise the timeliness of diagnostic responses. This challenge is exacerbated by the increasing complexity of engine control algorithms that require more sophisticated signal processing techniques.

Sensor degradation represents a persistent reliability issue. Environmental factors such as extreme temperatures, chemical exposure, and vibration accelerate sensor wear, causing drift in calibration accuracy over time. This degradation often goes undetected until significant measurement errors occur, potentially leading to misdiagnosis of engine conditions.

Integration complexity across different monitoring subsystems creates compatibility challenges. The LT1 engine's various control modules often employ proprietary communication protocols, complicating efforts to establish a unified signal detection framework. This fragmentation results in redundant sensors and inefficient data utilization across the engine management ecosystem.

Cost constraints continue to limit widespread adoption of advanced signal detection technologies. While high-precision sensors and sophisticated processing algorithms exist, their implementation costs remain prohibitive for mass-market applications, forcing compromises in detection capabilities.

Calibration complexity presents ongoing challenges for technicians and engineers. The interdependence of multiple signal parameters requires sophisticated calibration procedures that demand specialized expertise and equipment, increasing maintenance overhead and potential for misconfiguration.

Human-machine interface limitations also impact signal interpretation effectiveness. Current visualization tools often fail to present complex signal data in intuitive formats, making it difficult for technicians to quickly identify anomalies or patterns indicative of specific engine conditions.

Existing LT1 Signal Detection Methodologies

01 Acoustic signal detection methods for engine diagnostics

Acoustic signal detection methods involve capturing and analyzing sound waves generated by engine components to diagnose issues and monitor performance. These techniques use microphones or acoustic sensors strategically placed around the LT1 engine to detect abnormal sounds that may indicate mechanical problems, combustion irregularities, or component wear. Advanced signal processing algorithms filter out background noise and isolate specific frequency patterns associated with different engine conditions, enabling early detection of potential failures.- Engine knock detection methods: Various methods for detecting engine knock signals in LT1 engines involve specialized sensors and signal processing techniques. These methods typically analyze vibration patterns and acoustic signatures to identify abnormal combustion events. Advanced algorithms filter out background noise to isolate knock signals, allowing for real-time monitoring and engine protection. These detection systems help optimize engine performance while preventing damage from detonation events.

- Optical signal detection for engine diagnostics: Optical-based signal detection methods utilize light sensors and fiber optic technology to monitor LT1 engine parameters. These systems can detect combustion quality, fuel mixture properties, and emissions characteristics through spectral analysis. By measuring light intensity changes and wavelength shifts, these methods provide non-intrusive monitoring capabilities. Optical detection offers advantages in environments with high electromagnetic interference where traditional sensors might be compromised.

- Vibration-based signal processing techniques: Vibration analysis techniques for LT1 engines involve accelerometers and specialized signal processing algorithms to extract meaningful data from mechanical oscillations. These methods can identify specific engine conditions by analyzing frequency patterns, amplitude variations, and phase relationships. Advanced filtering techniques help separate relevant signals from mechanical noise, enabling precise detection of engine operating conditions and potential failure modes.

- Machine learning approaches for signal detection: Machine learning algorithms are increasingly applied to LT1 engine signal detection to improve accuracy and enable predictive diagnostics. These approaches use neural networks, pattern recognition, and data fusion techniques to identify complex signal patterns that traditional methods might miss. By training on large datasets of engine operation, these systems can detect subtle anomalies and classify different operating conditions with high precision, allowing for early fault detection and performance optimization.

- Integrated sensor networks for comprehensive signal detection: Integrated sensor networks combine multiple detection technologies to provide comprehensive monitoring of LT1 engine parameters. These systems synchronize data from various sensors including pressure transducers, temperature probes, and exhaust gas analyzers to create a holistic view of engine operation. Advanced signal correlation techniques enable cross-validation between different sensor inputs, improving reliability and enabling more sophisticated diagnostic capabilities through multi-parameter analysis.

02 Optical and laser-based signal detection for engine monitoring

Optical and laser-based detection methods utilize light signals to monitor various engine parameters in LT1 engines. These systems employ lasers, fiber optics, or other light-emitting devices to measure engine conditions without physical contact with moving parts. The technology can detect minute changes in engine component positions, combustion efficiency, and exhaust emissions through light reflection, absorption, or scattering patterns. Signal processing algorithms analyze these optical data streams to provide real-time feedback on engine performance and identify potential issues before they cause failures.Expand Specific Solutions03 Electronic sensor networks for comprehensive engine signal detection

Electronic sensor networks integrate multiple sensor types throughout the LT1 engine to provide comprehensive monitoring capabilities. These systems combine temperature, pressure, vibration, and position sensors with sophisticated data fusion algorithms to create a complete picture of engine operation. The networked approach allows for correlation between different signal types, enhancing diagnostic accuracy and enabling predictive maintenance. Advanced signal conditioning techniques filter electrical noise and compensate for environmental factors to ensure reliable detection even under challenging operating conditions.Expand Specific Solutions04 Vibration analysis methods for engine fault detection

Vibration analysis methods detect abnormal engine operation by monitoring mechanical oscillations produced by the LT1 engine. Accelerometers and vibration sensors mounted at strategic locations capture frequency patterns that correspond to specific engine components and operating conditions. Signal processing techniques such as Fast Fourier Transform (FFT) and wavelet analysis convert these vibration signals into frequency domain representations that reveal characteristic signatures of normal and faulty operation. Machine learning algorithms can be trained to recognize patterns associated with developing problems, enabling early intervention before catastrophic failures occur.Expand Specific Solutions05 Advanced signal processing algorithms for noise reduction and pattern recognition

Advanced signal processing algorithms enhance the detection capabilities of LT1 engine monitoring systems by filtering noise and identifying meaningful patterns in complex data streams. These computational methods employ digital filters, statistical analysis, and machine learning techniques to extract useful information from raw sensor signals. Adaptive filtering adjusts to changing engine conditions, while pattern recognition algorithms identify specific signatures associated with various engine states and fault conditions. Real-time processing capabilities allow for immediate detection of anomalies, while historical data analysis enables trend monitoring for predictive maintenance applications.Expand Specific Solutions

Leading Manufacturers and Competitors in Engine Diagnostics

The LT1 Engine Signal Detection market is currently in a growth phase, with increasing demand driven by automotive electrification and stricter emission regulations. The competitive landscape features established automotive suppliers like Robert Bosch GmbH, Continental Automotive, and DENSO leading technological innovation with mature signal detection solutions. These companies leverage extensive R&D capabilities and industry partnerships to maintain market dominance. Emerging players include specialized firms like Eldor Corp and United Automotive Electronic Systems, who are gaining traction through focused innovation. Academic institutions such as Tongji University and Zhejiang University contribute significantly to technological advancement through research collaborations with industry leaders, creating a dynamic ecosystem where both established manufacturers and new entrants compete to develop more precise, reliable, and cost-effective engine signal detection methods.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced LT1 engine signal detection methods utilizing integrated sensor networks and sophisticated digital signal processing algorithms. Their system employs high-precision knock sensors with adaptive filtering technology to detect combustion anomalies in real-time. The technology incorporates machine learning algorithms that continuously analyze engine vibration patterns to distinguish between normal combustion events and knocking phenomena. Bosch's approach integrates multiple signal sources including crankshaft position sensors, camshaft position sensors, and knock sensors to create a comprehensive engine monitoring system. Their proprietary signal conditioning circuits eliminate noise while preserving critical signal characteristics, enabling detection of subtle combustion irregularities that might indicate potential engine issues before they become serious problems.

Strengths: Superior noise rejection capabilities in harsh environments; highly integrated with other engine control systems; excellent detection accuracy across varying engine loads. Weaknesses: Higher implementation cost compared to simpler systems; requires significant computational resources; calibration complexity for different engine types.

Continental Automotive GmbH

Technical Solution: Continental Automotive has pioneered LT1 engine signal detection through their innovative Engine Management System (EMS) that utilizes advanced digital signal processing techniques. Their approach combines high-resolution crank angle sensing with sophisticated algorithms for precise timing detection. Continental's system employs frequency domain analysis to separate useful signals from noise, particularly focusing on the characteristic frequencies associated with LT1 engine operation. Their technology incorporates adaptive threshold detection that automatically adjusts to changing engine conditions and environmental factors. Continental has also developed specialized hardware with high sampling rates (up to 1 MHz) to capture transient events in engine operation that might be missed by conventional systems. Their integrated approach combines multiple sensor inputs with real-time processing to provide comprehensive engine performance monitoring.

Strengths: Exceptional signal-to-noise ratio in challenging conditions; highly adaptable to various engine configurations; seamless integration with existing vehicle electronic architecture. Weaknesses: Requires significant processing power; complex calibration procedures; higher cost compared to traditional detection methods.

Critical Patents and Innovations in Engine Signal Analysis

Stall warning detector for gas turbine engine

PatentInactiveCA1071435A

Innovation

- A stall warning system that continuously monitors turbine inlet or exit temperature and compressor speed, producing an output signal when both parameters exceed predetermined values, which can trigger a warning or initiate corrective actions such as fuel de-riching, opening compressor bleeds, or changing engine geometry.

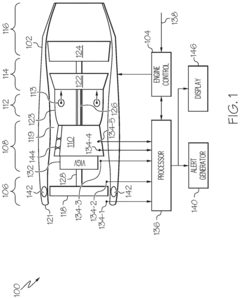

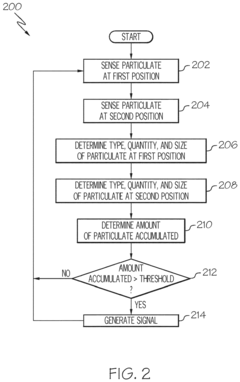

Gas turbine engine particulate ingestion detection system and corresponding method

PatentActiveEP3392467A1

Innovation

- A system comprising first and second particulate sensors mounted at specific positions on the engine, coupled with a processor to determine the type, quantity, and size of particulate, and calculate the amount accumulated, with the ability to compare this to a threshold value and generate alerts or initiate corrective actions.

Reliability and Performance Metrics for Signal Detection Systems

Reliability and performance metrics serve as critical benchmarks for evaluating the effectiveness of signal detection systems in LT1 engine applications. These metrics provide quantifiable measures that enable engineers to assess system capabilities under various operating conditions. Signal-to-noise ratio (SNR) stands as a fundamental metric, indicating the strength of desired signals relative to background noise. For LT1 engine signal detection, an SNR of at least 20dB is typically required to ensure accurate interpretation of critical engine parameters such as knock detection and misfire identification.

Detection probability and false alarm rates constitute another essential pair of metrics. Modern LT1 signal detection systems aim for detection probabilities exceeding 98% while maintaining false alarm rates below 0.1%. These metrics become particularly significant during transient engine operations where signal characteristics change rapidly. The receiver operating characteristic (ROC) curves derived from these parameters allow engineers to visualize the performance trade-offs inherent in detection threshold adjustments.

Response time metrics measure how quickly a detection system can identify and report signal events. For critical LT1 engine functions like detonation detection, response times under 5 milliseconds are necessary to prevent engine damage. This metric directly impacts the system's ability to implement timely corrective actions through the engine control unit (ECU).

Robustness metrics evaluate system performance under non-ideal conditions, including temperature extremes, electromagnetic interference, and aging effects. LT1 signal detection systems must maintain specified performance levels across the vehicle's operational temperature range (-40°C to 125°C) and throughout the expected service life of 150,000+ miles. Mean time between failures (MTBF) ratings typically exceed 10,000 hours for automotive-grade signal detection components.

Calibration stability represents another crucial metric, measuring how well detection parameters maintain their settings over time. Signal detection systems for LT1 engines should demonstrate drift rates below 1% per year to minimize maintenance requirements and ensure consistent engine performance. Self-diagnostic capabilities that can identify when recalibration is needed have become standard features in premium detection systems.

Resource utilization metrics track computational and power requirements. Modern signal detection implementations must balance performance with efficiency, particularly in battery-powered applications. Typical power consumption targets for signal conditioning and detection circuits fall below 50mW during normal operation, with advanced sleep modes reducing this to microwatt levels during vehicle standby periods.

Detection probability and false alarm rates constitute another essential pair of metrics. Modern LT1 signal detection systems aim for detection probabilities exceeding 98% while maintaining false alarm rates below 0.1%. These metrics become particularly significant during transient engine operations where signal characteristics change rapidly. The receiver operating characteristic (ROC) curves derived from these parameters allow engineers to visualize the performance trade-offs inherent in detection threshold adjustments.

Response time metrics measure how quickly a detection system can identify and report signal events. For critical LT1 engine functions like detonation detection, response times under 5 milliseconds are necessary to prevent engine damage. This metric directly impacts the system's ability to implement timely corrective actions through the engine control unit (ECU).

Robustness metrics evaluate system performance under non-ideal conditions, including temperature extremes, electromagnetic interference, and aging effects. LT1 signal detection systems must maintain specified performance levels across the vehicle's operational temperature range (-40°C to 125°C) and throughout the expected service life of 150,000+ miles. Mean time between failures (MTBF) ratings typically exceed 10,000 hours for automotive-grade signal detection components.

Calibration stability represents another crucial metric, measuring how well detection parameters maintain their settings over time. Signal detection systems for LT1 engines should demonstrate drift rates below 1% per year to minimize maintenance requirements and ensure consistent engine performance. Self-diagnostic capabilities that can identify when recalibration is needed have become standard features in premium detection systems.

Resource utilization metrics track computational and power requirements. Modern signal detection implementations must balance performance with efficiency, particularly in battery-powered applications. Typical power consumption targets for signal conditioning and detection circuits fall below 50mW during normal operation, with advanced sleep modes reducing this to microwatt levels during vehicle standby periods.

Environmental Impact and Emissions Compliance Considerations

The LT1 engine's signal detection methods have significant implications for environmental impact and emissions compliance. Modern regulatory frameworks, particularly those established by the Environmental Protection Agency (EPA) and European Union's Euro standards, have progressively tightened emissions requirements for internal combustion engines. The LT1's advanced signal detection systems play a crucial role in meeting these stringent standards by enabling precise control over the combustion process.

Signal detection in the LT1 engine directly influences air-fuel ratio management, which is fundamental to emissions control. When sensors accurately detect oxygen levels in exhaust gases, the engine control unit can make real-time adjustments to maintain optimal combustion efficiency. This precision significantly reduces the production of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC) - pollutants strictly regulated by environmental agencies worldwide.

The knock sensor signal detection capabilities of the LT1 engine represent another critical environmental consideration. By precisely identifying detonation events, these systems allow the engine to operate closer to its efficiency threshold without risking damage. This optimization translates to lower fuel consumption and reduced carbon dioxide emissions per mile traveled, supporting compliance with greenhouse gas regulations and corporate average fuel economy (CAFE) standards.

Emissions compliance testing increasingly focuses on real-world driving conditions rather than laboratory settings alone. The LT1's comprehensive signal detection network, including temperature sensors, mass airflow sensors, and crankshaft position sensors, enables adaptive strategies that maintain emissions compliance across diverse operating environments. This adaptability is particularly important as regulatory bodies implement more sophisticated testing protocols like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP).

Diagnostic capabilities enabled by the LT1's signal detection systems also contribute to long-term environmental performance. On-board diagnostics (OBD-II) continuously monitor emissions-related components, alerting drivers when systems operate outside acceptable parameters. This early warning system ensures timely maintenance, preventing vehicles from operating in high-emission states and extending the useful life of catalytic converters and other emissions control devices.

Future emissions regulations will likely demand even greater precision in engine management. The evolution of LT1 signal detection methods toward higher sampling rates, improved signal-to-noise ratios, and more sophisticated filtering algorithms positions this technology to meet increasingly stringent environmental standards. Manufacturers implementing these advanced detection methods gain competitive advantages in markets where emissions compliance represents both a regulatory requirement and a marketing differentiator.

Signal detection in the LT1 engine directly influences air-fuel ratio management, which is fundamental to emissions control. When sensors accurately detect oxygen levels in exhaust gases, the engine control unit can make real-time adjustments to maintain optimal combustion efficiency. This precision significantly reduces the production of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC) - pollutants strictly regulated by environmental agencies worldwide.

The knock sensor signal detection capabilities of the LT1 engine represent another critical environmental consideration. By precisely identifying detonation events, these systems allow the engine to operate closer to its efficiency threshold without risking damage. This optimization translates to lower fuel consumption and reduced carbon dioxide emissions per mile traveled, supporting compliance with greenhouse gas regulations and corporate average fuel economy (CAFE) standards.

Emissions compliance testing increasingly focuses on real-world driving conditions rather than laboratory settings alone. The LT1's comprehensive signal detection network, including temperature sensors, mass airflow sensors, and crankshaft position sensors, enables adaptive strategies that maintain emissions compliance across diverse operating environments. This adaptability is particularly important as regulatory bodies implement more sophisticated testing protocols like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP).

Diagnostic capabilities enabled by the LT1's signal detection systems also contribute to long-term environmental performance. On-board diagnostics (OBD-II) continuously monitor emissions-related components, alerting drivers when systems operate outside acceptable parameters. This early warning system ensures timely maintenance, preventing vehicles from operating in high-emission states and extending the useful life of catalytic converters and other emissions control devices.

Future emissions regulations will likely demand even greater precision in engine management. The evolution of LT1 signal detection methods toward higher sampling rates, improved signal-to-noise ratios, and more sophisticated filtering algorithms positions this technology to meet increasingly stringent environmental standards. Manufacturers implementing these advanced detection methods gain competitive advantages in markets where emissions compliance represents both a regulatory requirement and a marketing differentiator.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!