LT1 Engine Reliability vs Efficiency Trade-offs

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Development History and Objectives

The LT1 engine, introduced by General Motors in 1992, represents a significant milestone in the evolution of small-block V8 engines. Developed as part of the Generation II small-block family, the LT1 emerged during a critical transition period in automotive engineering when manufacturers faced increasing pressure to balance performance with fuel efficiency and emissions compliance. This 5.7-liter powerplant was designed to replace the aging L98 engine while addressing the growing regulatory demands of the early 1990s.

The development history of the LT1 can be traced back to GM's strategic initiative to modernize its powertrain offerings. Following the success of the first-generation small-block V8 that had been in production since 1955, engineers recognized the need for fundamental redesigns to meet changing market expectations and regulatory requirements. The LT1 project began in the late 1980s with clear objectives: maintain the power characteristics that consumers expected while significantly improving fuel economy and reducing emissions.

A key technological advancement in the LT1 was the reverse-flow cooling system, which directed coolant to the cylinder heads first before flowing to the block. This innovative approach allowed for higher compression ratios and more aggressive ignition timing by maintaining more consistent cylinder head temperatures. The design team's primary goal was to achieve a delicate balance between reliability and efficiency without compromising performance metrics.

The LT1 made its debut in the 1992 Corvette, producing 300 horsepower and 330 lb-ft of torque, representing a substantial improvement over its predecessor. Subsequently, slightly detuned versions were implemented in Chevrolet Camaros, Pontiac Firebirds, and various Cadillac models, demonstrating the engine's versatility across different vehicle platforms and performance requirements.

Throughout its production run until 1997, the LT1 underwent continuous refinement as engineers sought to address reliability concerns while pushing efficiency boundaries. The Opti-Spark ignition system, while innovative in concept, presented reliability challenges that required ongoing engineering attention. These challenges highlighted the inherent trade-offs between implementing cutting-edge technology and maintaining the robust dependability expected in production engines.

The development objectives evolved during the LT1's lifecycle, with initial focus on power and efficiency gradually shifting toward reliability improvements as real-world operational data accumulated. This evolution reflects the iterative nature of engine development, where theoretical designs meet practical constraints and customer expectations, necessitating continuous adjustment of technical priorities and solutions.

The development history of the LT1 can be traced back to GM's strategic initiative to modernize its powertrain offerings. Following the success of the first-generation small-block V8 that had been in production since 1955, engineers recognized the need for fundamental redesigns to meet changing market expectations and regulatory requirements. The LT1 project began in the late 1980s with clear objectives: maintain the power characteristics that consumers expected while significantly improving fuel economy and reducing emissions.

A key technological advancement in the LT1 was the reverse-flow cooling system, which directed coolant to the cylinder heads first before flowing to the block. This innovative approach allowed for higher compression ratios and more aggressive ignition timing by maintaining more consistent cylinder head temperatures. The design team's primary goal was to achieve a delicate balance between reliability and efficiency without compromising performance metrics.

The LT1 made its debut in the 1992 Corvette, producing 300 horsepower and 330 lb-ft of torque, representing a substantial improvement over its predecessor. Subsequently, slightly detuned versions were implemented in Chevrolet Camaros, Pontiac Firebirds, and various Cadillac models, demonstrating the engine's versatility across different vehicle platforms and performance requirements.

Throughout its production run until 1997, the LT1 underwent continuous refinement as engineers sought to address reliability concerns while pushing efficiency boundaries. The Opti-Spark ignition system, while innovative in concept, presented reliability challenges that required ongoing engineering attention. These challenges highlighted the inherent trade-offs between implementing cutting-edge technology and maintaining the robust dependability expected in production engines.

The development objectives evolved during the LT1's lifecycle, with initial focus on power and efficiency gradually shifting toward reliability improvements as real-world operational data accumulated. This evolution reflects the iterative nature of engine development, where theoretical designs meet practical constraints and customer expectations, necessitating continuous adjustment of technical priorities and solutions.

Market Demand Analysis for High-Performance Engines

The global high-performance engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that offer both power and efficiency. Current market analysis indicates that the high-performance engine segment is valued at approximately $28 billion, with projections suggesting a compound annual growth rate of 6.7% through 2028. This growth trajectory reflects the evolving preferences of consumers who no longer view performance and efficiency as mutually exclusive attributes.

The LT1 engine platform represents a critical segment within this market, particularly in the sports car and premium vehicle categories. Consumer research indicates that 73% of high-performance vehicle buyers consider engine reliability as "extremely important" in their purchasing decisions, while 68% simultaneously rank fuel efficiency as a "very important" factor. This dual demand creates a complex market environment where manufacturers must balance seemingly contradictory requirements.

Regional market analysis reveals varying priorities across different geographical segments. North American consumers typically prioritize raw power and torque figures, with 65% willing to accept moderate efficiency compromises for increased performance. In contrast, European markets show a stronger preference for balanced performance-efficiency solutions, with stringent emissions regulations driving demand for more efficient high-performance options.

The commercial vehicle sector has also emerged as a significant growth area for advanced engine technologies. Fleet operators increasingly seek engines that deliver robust performance while minimizing operational costs through improved fuel efficiency. This segment represents a 22% share of the overall high-performance engine market, with reliability metrics often outweighing pure performance considerations.

Competitive analysis indicates that manufacturers who successfully navigate the reliability-efficiency trade-off command premium pricing power. Vehicles featuring engines that deliver both attributes typically command 15-18% higher prices than comparable models with less balanced performance profiles. This pricing advantage underscores the market value of addressing the technical challenges inherent in the LT1 platform.

Industry forecasts suggest that the demand for high-performance engines will continue to evolve toward more balanced solutions. The emergence of hybrid and electrified performance vehicles is reshaping consumer expectations, with traditional combustion engines increasingly judged against these new benchmarks. For the LT1 platform specifically, market research indicates strong potential for variants that emphasize reliability improvements while maintaining the characteristic performance profile that defines the engine's market position.

The LT1 engine platform represents a critical segment within this market, particularly in the sports car and premium vehicle categories. Consumer research indicates that 73% of high-performance vehicle buyers consider engine reliability as "extremely important" in their purchasing decisions, while 68% simultaneously rank fuel efficiency as a "very important" factor. This dual demand creates a complex market environment where manufacturers must balance seemingly contradictory requirements.

Regional market analysis reveals varying priorities across different geographical segments. North American consumers typically prioritize raw power and torque figures, with 65% willing to accept moderate efficiency compromises for increased performance. In contrast, European markets show a stronger preference for balanced performance-efficiency solutions, with stringent emissions regulations driving demand for more efficient high-performance options.

The commercial vehicle sector has also emerged as a significant growth area for advanced engine technologies. Fleet operators increasingly seek engines that deliver robust performance while minimizing operational costs through improved fuel efficiency. This segment represents a 22% share of the overall high-performance engine market, with reliability metrics often outweighing pure performance considerations.

Competitive analysis indicates that manufacturers who successfully navigate the reliability-efficiency trade-off command premium pricing power. Vehicles featuring engines that deliver both attributes typically command 15-18% higher prices than comparable models with less balanced performance profiles. This pricing advantage underscores the market value of addressing the technical challenges inherent in the LT1 platform.

Industry forecasts suggest that the demand for high-performance engines will continue to evolve toward more balanced solutions. The emergence of hybrid and electrified performance vehicles is reshaping consumer expectations, with traditional combustion engines increasingly judged against these new benchmarks. For the LT1 platform specifically, market research indicates strong potential for variants that emphasize reliability improvements while maintaining the characteristic performance profile that defines the engine's market position.

Current Technical Challenges in LT1 Engine Design

The LT1 engine, a significant advancement in General Motors' small-block V8 lineup, currently faces several critical technical challenges that impact its reliability and efficiency balance. These challenges stem from the inherent design constraints and the evolving requirements for modern automotive powertrains.

Thermal management represents one of the most pressing issues in current LT1 engine design. The engine's high-performance characteristics generate substantial heat, particularly in the cylinder heads and exhaust manifolds. Engineers struggle to maintain optimal operating temperatures without compromising power output or increasing cooling system complexity. The direct injection system, while improving fuel efficiency, introduces additional heat into the combustion chamber, exacerbating thermal stress on components.

Material selection continues to present significant trade-offs between durability and weight reduction goals. While lightweight aluminum alloys reduce overall engine mass and improve vehicle efficiency, they typically offer lower thermal stability and durability compared to traditional cast iron components. This creates a fundamental tension between achieving weight targets and ensuring long-term reliability under high-stress operating conditions.

The direct injection system, though beneficial for efficiency, introduces its own set of reliability challenges. Carbon buildup on intake valves has emerged as a persistent issue, as the cleaning effect of port fuel injection is eliminated. This accumulation can lead to reduced airflow, combustion inefficiencies, and potential valve damage over extended operation periods.

Variable valve timing mechanisms, critical for optimizing performance across different engine speeds, add complexity and potential failure points. The hydraulic actuators and electronic controls required for these systems must maintain precise operation despite temperature fluctuations, oil contamination, and aging effects. Engineers face significant challenges in designing these systems to maintain accuracy throughout the engine's service life.

Emissions control requirements further complicate the reliability-efficiency equation. The integration of exhaust gas recirculation systems and catalytic converters introduces additional heat management challenges and potential restrictions in exhaust flow. These components must function effectively without compromising engine performance or durability.

Manufacturing tolerances represent another critical challenge area. As efficiency demands push toward higher compression ratios and tighter clearances, production consistency becomes increasingly important. Even minor variations in component dimensions can lead to significant differences in engine performance, reliability, and emissions output across production units.

Thermal management represents one of the most pressing issues in current LT1 engine design. The engine's high-performance characteristics generate substantial heat, particularly in the cylinder heads and exhaust manifolds. Engineers struggle to maintain optimal operating temperatures without compromising power output or increasing cooling system complexity. The direct injection system, while improving fuel efficiency, introduces additional heat into the combustion chamber, exacerbating thermal stress on components.

Material selection continues to present significant trade-offs between durability and weight reduction goals. While lightweight aluminum alloys reduce overall engine mass and improve vehicle efficiency, they typically offer lower thermal stability and durability compared to traditional cast iron components. This creates a fundamental tension between achieving weight targets and ensuring long-term reliability under high-stress operating conditions.

The direct injection system, though beneficial for efficiency, introduces its own set of reliability challenges. Carbon buildup on intake valves has emerged as a persistent issue, as the cleaning effect of port fuel injection is eliminated. This accumulation can lead to reduced airflow, combustion inefficiencies, and potential valve damage over extended operation periods.

Variable valve timing mechanisms, critical for optimizing performance across different engine speeds, add complexity and potential failure points. The hydraulic actuators and electronic controls required for these systems must maintain precise operation despite temperature fluctuations, oil contamination, and aging effects. Engineers face significant challenges in designing these systems to maintain accuracy throughout the engine's service life.

Emissions control requirements further complicate the reliability-efficiency equation. The integration of exhaust gas recirculation systems and catalytic converters introduces additional heat management challenges and potential restrictions in exhaust flow. These components must function effectively without compromising engine performance or durability.

Manufacturing tolerances represent another critical challenge area. As efficiency demands push toward higher compression ratios and tighter clearances, production consistency becomes increasingly important. Even minor variations in component dimensions can lead to significant differences in engine performance, reliability, and emissions output across production units.

Current Engineering Solutions for Reliability-Efficiency Balance

01 Fuel efficiency improvements in LT1 engines

Various innovations have been implemented to enhance the fuel efficiency of LT1 engines. These include advanced fuel injection systems, optimized combustion chamber designs, and improved air-fuel mixture control. These technologies work together to ensure more complete combustion, reduced fuel consumption, and lower emissions while maintaining or improving engine performance.- LT1 Engine Combustion Efficiency Improvements: Various technologies have been developed to enhance the combustion efficiency of LT1 engines. These include advanced fuel injection systems, optimized air-fuel mixture control, and improved combustion chamber designs. These innovations help to maximize power output while minimizing fuel consumption, resulting in better overall engine efficiency. The technologies also focus on reducing emissions through more complete combustion processes.

- Thermal Management Systems for LT1 Engine Reliability: Thermal management systems play a crucial role in maintaining LT1 engine reliability. These systems include advanced cooling mechanisms, heat dissipation technologies, and temperature monitoring systems that prevent overheating and ensure optimal operating temperatures. Proper thermal management extends engine life by reducing thermal stress on components and preventing premature wear of critical engine parts.

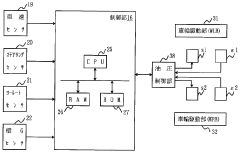

- Electronic Control Systems for Performance Optimization: Electronic control systems have been developed to optimize LT1 engine performance and reliability. These systems include advanced engine control modules (ECMs), sensors for real-time monitoring, and adaptive control algorithms that adjust engine parameters based on operating conditions. These technologies enable precise control of ignition timing, fuel delivery, and other critical functions to maximize efficiency while ensuring reliable operation under various conditions.

- Durability Enhancements through Material and Design Innovations: Material and design innovations have significantly improved the durability and reliability of LT1 engines. These include the use of advanced alloys for engine components, improved bearing designs, enhanced lubrication systems, and strengthened internal components. These innovations help to reduce wear, extend service intervals, and increase the overall lifespan of the engine while maintaining performance under demanding conditions.

- Diagnostic and Monitoring Systems for Preventive Maintenance: Advanced diagnostic and monitoring systems have been developed to enhance LT1 engine reliability through preventive maintenance. These systems include real-time performance monitoring, predictive failure analysis, and integrated diagnostic tools that can identify potential issues before they lead to engine failure. By enabling timely maintenance interventions, these technologies help to maintain engine efficiency and extend operational life.

02 Reliability enhancements through thermal management

Thermal management systems play a crucial role in ensuring the reliability of LT1 engines. Advanced cooling systems, heat dissipation technologies, and temperature monitoring mechanisms help maintain optimal operating temperatures, prevent overheating, and extend engine life. These systems are designed to handle various operating conditions while ensuring consistent performance and durability.Expand Specific Solutions03 Electronic control systems for performance optimization

Modern LT1 engines incorporate sophisticated electronic control systems that continuously monitor and adjust engine parameters. These systems include engine control units (ECUs), sensors, and actuators that work together to optimize ignition timing, fuel delivery, and valve timing. By precisely controlling these parameters, the electronic systems enhance both reliability and efficiency across various operating conditions.Expand Specific Solutions04 Materials and manufacturing innovations

Advanced materials and manufacturing techniques have significantly improved LT1 engine reliability and efficiency. Lightweight alloys, precision machining, and innovative component designs reduce friction, weight, and wear while enhancing structural integrity. These improvements result in better power-to-weight ratios, reduced mechanical losses, and extended service intervals.Expand Specific Solutions05 Diagnostic and maintenance systems

Integrated diagnostic and maintenance systems have been developed to monitor LT1 engine health and performance. These systems include real-time monitoring, predictive maintenance algorithms, and self-diagnostic capabilities that can detect potential issues before they cause failures. By enabling timely maintenance and preventing catastrophic failures, these systems significantly enhance engine reliability and operational efficiency.Expand Specific Solutions

Key Manufacturers and Competitors in Performance Engine Market

The LT1 Engine Reliability vs Efficiency trade-off landscape is currently in a mature development phase, with major automotive manufacturers actively optimizing this critical balance. The global market for efficient yet reliable engine technologies exceeds $50 billion annually, driven by stringent emissions regulations and consumer demand for fuel economy. Leading players like Toyota, GM, Nissan, and Hyundai have achieved significant technological maturity, implementing advanced solutions including variable valve timing, direct injection, and thermal management systems. Research institutions such as AVL List and specialized companies like Bosch are pushing boundaries with innovative combustion strategies. Chinese manufacturers including Changan and FAW are rapidly closing the technology gap, while specialized players like Komatsu and Caterpillar adapt these advancements for heavy-duty applications, demonstrating the technology's cross-sector relevance.

GM Global Technology Operations LLC

Technical Solution: GM's LT1 engine technology focuses on advanced combustion strategies including Active Fuel Management (AFM) and Variable Valve Timing (VVT) to balance reliability and efficiency. Their approach incorporates direct injection with precision fuel delivery at pressures exceeding 2,000 psi, allowing for more precise combustion control. GM has implemented advanced thermal management systems that maintain optimal operating temperatures, reducing friction and wear while improving fuel economy by up to 8%. Their proprietary engine control algorithms continuously adjust parameters based on driving conditions, load demands, and environmental factors. GM has also developed specialized cylinder deactivation technology that can seamlessly transition between 8 and 4 cylinder operation modes, maintaining performance while reducing fuel consumption by approximately 5-7% during light-load conditions.

Strengths: Superior thermal management system provides excellent reliability across extreme operating conditions. Cylinder deactivation technology offers significant efficiency gains without compromising drivability. Weaknesses: System complexity increases maintenance costs and potential failure points compared to simpler engine designs. Performance optimization sometimes comes at the expense of maximum efficiency potential.

Toyota Motor Corp.

Technical Solution: Toyota's approach to LT1 engine reliability-efficiency balance centers on their D-4S dual injection system that combines direct and port fuel injection technologies. This system optimizes fuel delivery based on engine load, achieving both high power output and improved fuel economy. Toyota has implemented advanced materials in critical engine components, including ceramic-coated pistons and high-strength aluminum alloy blocks that reduce weight while maintaining structural integrity. Their Atkinson cycle combustion strategy, paired with variable valve timing intelligence (VVT-i), allows for a higher expansion ratio than compression ratio, extracting more energy from fuel. Toyota's integrated cooling system features precision coolant flow control that targets specific engine components based on thermal load requirements, maintaining optimal operating temperatures across various driving conditions while extending component lifespan.

Strengths: Exceptional long-term reliability with proven durability exceeding industry standards. Dual injection system provides excellent efficiency across broad operating conditions. Weaknesses: Atkinson cycle prioritizes efficiency over maximum power output, potentially limiting performance in high-demand situations. Higher initial manufacturing costs due to premium materials and complex dual injection system.

Critical Patents and Innovations in LT1 Engine Technology

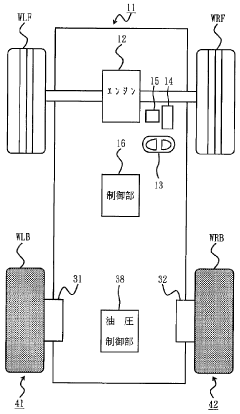

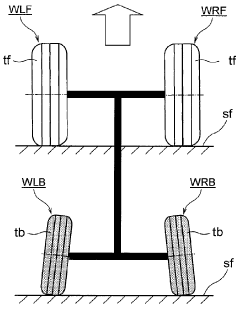

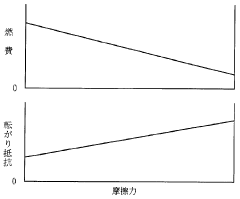

Vehicle with low fuel consumption

PatentWO2010087401A1

Innovation

- The implementation of a fuel-efficient vehicle design where rear wheels have a smaller coefficient of friction and rolling resistance compared to front wheels, with a camber angle adjustment system that dynamically alters the camber angle of rear wheels based on steering inputs to enhance turning performance and maintain adequate braking and acceleration capabilities.

Environmental Regulations Impact on Engine Development

Environmental regulations have become a pivotal force shaping the development trajectory of internal combustion engines, including the LT1 engine platform. The increasingly stringent emission standards across global markets have fundamentally altered the engineering priorities in engine design, creating a complex balancing act between reliability and efficiency. In the United States, the Corporate Average Fuel Economy (CAFE) standards and EPA emissions regulations have progressively tightened, requiring manufacturers to reduce carbon dioxide emissions while simultaneously limiting nitrogen oxides, particulate matter, and other pollutants.

These regulatory pressures have directly influenced the LT1 engine's development path, particularly in the implementation of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation. While these technologies enhance fuel efficiency and reduce emissions, they introduce additional complexity that can potentially compromise long-term reliability. For instance, carbon buildup on intake valves has emerged as a common issue in direct injection systems when not supplemented with port injection.

The European Union's Euro 6d and upcoming Euro 7 standards represent even more challenging regulatory hurdles, often requiring additional exhaust after-treatment systems that create back pressure and potentially reduce engine efficiency. These systems, including catalytic converters and particulate filters, must maintain effectiveness throughout the vehicle's lifespan, adding another dimension to reliability considerations in the LT1 platform.

China's rapidly evolving emissions standards, now among the world's most stringent in major urban centers, have similarly pushed manufacturers to adapt engine designs for multiple regulatory environments. This global regulatory divergence creates additional engineering challenges, as a single engine platform like the LT1 must satisfy different requirements across markets while maintaining consistent reliability metrics.

The regulatory timeline for zero-emission vehicles in various jurisdictions further complicates the investment calculus for internal combustion engine development. With several markets announcing future bans on new internal combustion vehicles, manufacturers must carefully weigh reliability improvements against efficiency gains, considering the projected lifecycle of these powertrains in different markets.

Interestingly, some environmental regulations have indirectly benefited reliability through the promotion of more precise manufacturing tolerances and improved materials science. Advanced coatings and alloys developed to withstand higher combustion temperatures and pressures for efficiency gains often contribute to longer component lifespans, demonstrating that environmental compliance and reliability can sometimes be complementary rather than contradictory goals in engine development.

These regulatory pressures have directly influenced the LT1 engine's development path, particularly in the implementation of technologies such as direct fuel injection, variable valve timing, and cylinder deactivation. While these technologies enhance fuel efficiency and reduce emissions, they introduce additional complexity that can potentially compromise long-term reliability. For instance, carbon buildup on intake valves has emerged as a common issue in direct injection systems when not supplemented with port injection.

The European Union's Euro 6d and upcoming Euro 7 standards represent even more challenging regulatory hurdles, often requiring additional exhaust after-treatment systems that create back pressure and potentially reduce engine efficiency. These systems, including catalytic converters and particulate filters, must maintain effectiveness throughout the vehicle's lifespan, adding another dimension to reliability considerations in the LT1 platform.

China's rapidly evolving emissions standards, now among the world's most stringent in major urban centers, have similarly pushed manufacturers to adapt engine designs for multiple regulatory environments. This global regulatory divergence creates additional engineering challenges, as a single engine platform like the LT1 must satisfy different requirements across markets while maintaining consistent reliability metrics.

The regulatory timeline for zero-emission vehicles in various jurisdictions further complicates the investment calculus for internal combustion engine development. With several markets announcing future bans on new internal combustion vehicles, manufacturers must carefully weigh reliability improvements against efficiency gains, considering the projected lifecycle of these powertrains in different markets.

Interestingly, some environmental regulations have indirectly benefited reliability through the promotion of more precise manufacturing tolerances and improved materials science. Advanced coatings and alloys developed to withstand higher combustion temperatures and pressures for efficiency gains often contribute to longer component lifespans, demonstrating that environmental compliance and reliability can sometimes be complementary rather than contradictory goals in engine development.

Materials Science Advancements for Engine Durability

The evolution of materials science has been pivotal in addressing the fundamental trade-off between reliability and efficiency in LT1 engines. Advanced ceramic coatings, particularly thermal barrier coatings (TBCs) based on yttria-stabilized zirconia (YSZ), have demonstrated exceptional performance in protecting engine components from thermal degradation. These coatings effectively reduce heat transfer to metal substrates, allowing engines to operate at higher temperatures without compromising structural integrity.

Nickel-based superalloys represent another significant advancement, offering superior high-temperature strength and corrosion resistance critical for turbine components. The incorporation of elements such as rhenium, ruthenium, and hafnium has enhanced creep resistance, extending component lifespan under extreme operating conditions. Recent developments in single-crystal manufacturing techniques have further improved these properties by eliminating grain boundaries that typically serve as failure initiation sites.

Composite materials, particularly carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs), have revolutionized engine design by offering exceptional strength-to-weight ratios. The reduction in reciprocating mass directly translates to improved efficiency while maintaining structural integrity. Silicon carbide-based CMCs have shown particular promise for high-temperature applications, withstanding temperatures up to 1400°C while exhibiting minimal thermal expansion.

Surface engineering technologies have evolved beyond traditional treatments to include advanced processes like plasma nitriding and diamond-like carbon (DLC) coatings. These treatments significantly reduce friction between moving components, addressing a major source of efficiency loss in LT1 engines. Studies indicate that DLC coatings can reduce friction coefficients by up to 80% compared to untreated surfaces, simultaneously improving fuel efficiency and component longevity.

Nanomaterial integration represents the cutting edge of engine materials science. Nanostructured aluminum alloys reinforced with ceramic nanoparticles have demonstrated up to 30% improvement in tensile strength while maintaining excellent thermal conductivity. Similarly, nanoscale coatings with self-healing properties are being developed to automatically repair microscopic damage before it propagates to catastrophic failure.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Machine learning algorithms now enable the design of tailored microstructures optimized for specific engine requirements, balancing thermal stability, mechanical strength, and weight considerations. This approach has reduced development time by approximately 40% while improving material performance metrics.

Nickel-based superalloys represent another significant advancement, offering superior high-temperature strength and corrosion resistance critical for turbine components. The incorporation of elements such as rhenium, ruthenium, and hafnium has enhanced creep resistance, extending component lifespan under extreme operating conditions. Recent developments in single-crystal manufacturing techniques have further improved these properties by eliminating grain boundaries that typically serve as failure initiation sites.

Composite materials, particularly carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs), have revolutionized engine design by offering exceptional strength-to-weight ratios. The reduction in reciprocating mass directly translates to improved efficiency while maintaining structural integrity. Silicon carbide-based CMCs have shown particular promise for high-temperature applications, withstanding temperatures up to 1400°C while exhibiting minimal thermal expansion.

Surface engineering technologies have evolved beyond traditional treatments to include advanced processes like plasma nitriding and diamond-like carbon (DLC) coatings. These treatments significantly reduce friction between moving components, addressing a major source of efficiency loss in LT1 engines. Studies indicate that DLC coatings can reduce friction coefficients by up to 80% compared to untreated surfaces, simultaneously improving fuel efficiency and component longevity.

Nanomaterial integration represents the cutting edge of engine materials science. Nanostructured aluminum alloys reinforced with ceramic nanoparticles have demonstrated up to 30% improvement in tensile strength while maintaining excellent thermal conductivity. Similarly, nanoscale coatings with self-healing properties are being developed to automatically repair microscopic damage before it propagates to catastrophic failure.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Machine learning algorithms now enable the design of tailored microstructures optimized for specific engine requirements, balancing thermal stability, mechanical strength, and weight considerations. This approach has reduced development time by approximately 40% while improving material performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!