How to Upgrade LT1 Engine Software

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Software Evolution and Objectives

The LT1 engine, introduced by General Motors in the early 1990s, represents a significant milestone in automotive powertrain technology. This small-block V8 engine initially featured advanced electronic fuel injection systems that were revolutionary for their time. Over the decades, the LT1 engine software has evolved from basic engine control modules (ECMs) with limited functionality to sophisticated engine management systems capable of real-time adjustments and diagnostics.

The evolution of LT1 engine software can be traced through several distinct generations. The first-generation systems focused primarily on fuel delivery and ignition timing control. Second-generation software introduced more complex algorithms for emissions control and performance optimization. Current generation software incorporates advanced features such as variable valve timing control, cylinder deactivation management, and integration with vehicle stability systems.

Market demands and regulatory requirements have been primary drivers in this evolution. Increasingly stringent emissions standards have necessitated more precise control over combustion processes, while consumer expectations for performance, fuel economy, and reliability have pushed development toward more sophisticated control strategies. The software architecture has transitioned from monolithic designs to modular frameworks that allow for easier updates and customization.

The technical objectives for modern LT1 engine software upgrades center around four key areas: performance optimization, emissions reduction, fuel efficiency improvement, and diagnostic capabilities enhancement. Performance optimization involves refining air-fuel mixture ratios, ignition timing maps, and throttle response characteristics to maximize power output while maintaining drivability. Emissions reduction focuses on optimizing combustion efficiency and exhaust aftertreatment control strategies to meet or exceed regulatory requirements.

Fuel efficiency improvements target reduced consumption through advanced algorithms that optimize combustion timing, manage accessory loads, and implement intelligent thermal management. Enhanced diagnostic capabilities aim to provide more detailed information about engine operation, enabling predictive maintenance and faster troubleshooting of potential issues before they lead to failures.

Looking forward, the strategic objectives for LT1 engine software development include preparation for integration with hybrid powertrains, compatibility with alternative fuels, and implementation of over-the-air update capabilities. These objectives align with broader industry trends toward electrification, sustainability, and connected vehicle technologies. The technical roadmap must balance legacy support for existing hardware with forward-looking features that extend the useful life of LT1-equipped vehicles in an evolving automotive landscape.

The evolution of LT1 engine software can be traced through several distinct generations. The first-generation systems focused primarily on fuel delivery and ignition timing control. Second-generation software introduced more complex algorithms for emissions control and performance optimization. Current generation software incorporates advanced features such as variable valve timing control, cylinder deactivation management, and integration with vehicle stability systems.

Market demands and regulatory requirements have been primary drivers in this evolution. Increasingly stringent emissions standards have necessitated more precise control over combustion processes, while consumer expectations for performance, fuel economy, and reliability have pushed development toward more sophisticated control strategies. The software architecture has transitioned from monolithic designs to modular frameworks that allow for easier updates and customization.

The technical objectives for modern LT1 engine software upgrades center around four key areas: performance optimization, emissions reduction, fuel efficiency improvement, and diagnostic capabilities enhancement. Performance optimization involves refining air-fuel mixture ratios, ignition timing maps, and throttle response characteristics to maximize power output while maintaining drivability. Emissions reduction focuses on optimizing combustion efficiency and exhaust aftertreatment control strategies to meet or exceed regulatory requirements.

Fuel efficiency improvements target reduced consumption through advanced algorithms that optimize combustion timing, manage accessory loads, and implement intelligent thermal management. Enhanced diagnostic capabilities aim to provide more detailed information about engine operation, enabling predictive maintenance and faster troubleshooting of potential issues before they lead to failures.

Looking forward, the strategic objectives for LT1 engine software development include preparation for integration with hybrid powertrains, compatibility with alternative fuels, and implementation of over-the-air update capabilities. These objectives align with broader industry trends toward electrification, sustainability, and connected vehicle technologies. The technical roadmap must balance legacy support for existing hardware with forward-looking features that extend the useful life of LT1-equipped vehicles in an evolving automotive landscape.

Market Requirements for Engine Management Systems

The automotive engine management system market is experiencing significant growth driven by increasing demand for fuel-efficient vehicles and stricter emission regulations worldwide. Current market analysis indicates that engine management systems must deliver improved performance while meeting Euro 7, China 7, and EPA Tier 3 standards, creating substantial pressure for software upgrades in existing platforms like the LT1 engine.

Vehicle manufacturers are specifically demanding engine management systems that can optimize fuel consumption while maintaining or enhancing performance characteristics. For the LT1 engine platform, customers require software solutions that can reduce fuel consumption by at least 5-8% without compromising the engine's renowned power output. This market requirement stems from both regulatory pressures and consumer expectations for lower operating costs.

Emissions control represents another critical market requirement. Modern engine management systems must provide real-time monitoring and adjustment capabilities to ensure emissions remain within increasingly stringent limits across all driving conditions. For LT1 engine software upgrades, the market demands solutions that can reduce NOx emissions by up to 15% and particulate matter by 20% compared to previous software versions.

Diagnostic capabilities have become increasingly important in the market landscape. Fleet operators and individual vehicle owners expect comprehensive self-diagnostic features that can identify potential issues before they cause performance problems or emissions violations. The market requires LT1 software upgrades to include enhanced OBD (On-Board Diagnostics) functionality with predictive maintenance capabilities.

Connectivity represents a rapidly growing market requirement for engine management systems. Modern vehicles are expected to integrate with broader telematics systems, allowing for remote diagnostics, over-the-air updates, and data collection for fleet management. LT1 engine software upgrades must incorporate API interfaces that enable seamless integration with various telematics platforms.

Durability and reliability remain fundamental market requirements. Engine management software must maintain stable performance across the vehicle's lifetime, with minimal degradation. For LT1 engines, which are often deployed in performance and commercial applications, the market demands software that can maintain calibration accuracy over extended periods and under harsh operating conditions.

Customization capabilities are increasingly valued in specialized market segments. Performance vehicle manufacturers and aftermarket tuners require engine management systems that provide controlled access to parameters for optimization in specific use cases. The LT1 software upgrade market includes demand for tiered access systems that allow authorized modifications while preventing changes that could compromise emissions compliance or engine longevity.

Vehicle manufacturers are specifically demanding engine management systems that can optimize fuel consumption while maintaining or enhancing performance characteristics. For the LT1 engine platform, customers require software solutions that can reduce fuel consumption by at least 5-8% without compromising the engine's renowned power output. This market requirement stems from both regulatory pressures and consumer expectations for lower operating costs.

Emissions control represents another critical market requirement. Modern engine management systems must provide real-time monitoring and adjustment capabilities to ensure emissions remain within increasingly stringent limits across all driving conditions. For LT1 engine software upgrades, the market demands solutions that can reduce NOx emissions by up to 15% and particulate matter by 20% compared to previous software versions.

Diagnostic capabilities have become increasingly important in the market landscape. Fleet operators and individual vehicle owners expect comprehensive self-diagnostic features that can identify potential issues before they cause performance problems or emissions violations. The market requires LT1 software upgrades to include enhanced OBD (On-Board Diagnostics) functionality with predictive maintenance capabilities.

Connectivity represents a rapidly growing market requirement for engine management systems. Modern vehicles are expected to integrate with broader telematics systems, allowing for remote diagnostics, over-the-air updates, and data collection for fleet management. LT1 engine software upgrades must incorporate API interfaces that enable seamless integration with various telematics platforms.

Durability and reliability remain fundamental market requirements. Engine management software must maintain stable performance across the vehicle's lifetime, with minimal degradation. For LT1 engines, which are often deployed in performance and commercial applications, the market demands software that can maintain calibration accuracy over extended periods and under harsh operating conditions.

Customization capabilities are increasingly valued in specialized market segments. Performance vehicle manufacturers and aftermarket tuners require engine management systems that provide controlled access to parameters for optimization in specific use cases. The LT1 software upgrade market includes demand for tiered access systems that allow authorized modifications while preventing changes that could compromise emissions compliance or engine longevity.

Current LT1 Software Architecture and Limitations

The LT1 engine control software architecture is built on a hierarchical structure with three primary layers: hardware abstraction, core engine management, and application interfaces. The hardware abstraction layer provides direct communication with engine sensors and actuators, while the core management layer contains the critical algorithms for fuel delivery, ignition timing, and emissions control. The application interface layer facilitates diagnostics, calibration, and integration with vehicle systems.

This architecture, while robust for its original design parameters, exhibits several limitations when considering modern performance demands and emission standards. The current software utilizes a fixed-point arithmetic system with 16-bit processing capabilities, creating computational constraints when implementing more complex control algorithms. Memory allocation is particularly restrictive, with approximately 256KB of flash memory and 32KB of RAM, limiting the implementation of advanced features such as adaptive learning algorithms and comprehensive diagnostic routines.

The existing control logic employs predominantly lookup table-based strategies with limited interpolation capabilities. This approach, while computationally efficient, lacks the sophistication needed for optimized performance across all operating conditions. The fuel delivery system operates on a speed-density calculation model that becomes less accurate at extreme operating conditions, particularly during high-load transients or when aftermarket modifications are installed.

Communication protocols represent another significant limitation. The LT1 software utilizes an older variant of the OBD-II protocol with restricted bandwidth and limited parameter accessibility. This creates bottlenecks during diagnostics and tuning operations, extending service times and complicating aftermarket modifications. The proprietary nature of certain communication interfaces further restricts third-party development and integration capabilities.

The calibration framework presents additional challenges, as it was designed with limited parameterization options. Approximately 120 tunable parameters exist in the stock configuration, significantly fewer than modern engine management systems which typically offer 300-500 adjustable variables. This restriction limits fine-tuning capabilities, particularly for specialized applications or modified engines.

Security implementations in the current architecture lack modern encryption standards, making the system vulnerable to unauthorized modifications. While this has facilitated aftermarket development, it presents concerns regarding emissions compliance and warranty validation. The absence of robust validation routines allows potentially damaging calibrations to be implemented without sufficient safeguards.

Software update mechanisms rely on specialized hardware interfaces and proprietary tools, complicating the deployment of improvements and patches. The absence of over-the-air update capabilities necessitates physical access to the vehicle for any software modifications, increasing maintenance costs and reducing the feasibility of regular updates to address emerging issues or optimize performance.

This architecture, while robust for its original design parameters, exhibits several limitations when considering modern performance demands and emission standards. The current software utilizes a fixed-point arithmetic system with 16-bit processing capabilities, creating computational constraints when implementing more complex control algorithms. Memory allocation is particularly restrictive, with approximately 256KB of flash memory and 32KB of RAM, limiting the implementation of advanced features such as adaptive learning algorithms and comprehensive diagnostic routines.

The existing control logic employs predominantly lookup table-based strategies with limited interpolation capabilities. This approach, while computationally efficient, lacks the sophistication needed for optimized performance across all operating conditions. The fuel delivery system operates on a speed-density calculation model that becomes less accurate at extreme operating conditions, particularly during high-load transients or when aftermarket modifications are installed.

Communication protocols represent another significant limitation. The LT1 software utilizes an older variant of the OBD-II protocol with restricted bandwidth and limited parameter accessibility. This creates bottlenecks during diagnostics and tuning operations, extending service times and complicating aftermarket modifications. The proprietary nature of certain communication interfaces further restricts third-party development and integration capabilities.

The calibration framework presents additional challenges, as it was designed with limited parameterization options. Approximately 120 tunable parameters exist in the stock configuration, significantly fewer than modern engine management systems which typically offer 300-500 adjustable variables. This restriction limits fine-tuning capabilities, particularly for specialized applications or modified engines.

Security implementations in the current architecture lack modern encryption standards, making the system vulnerable to unauthorized modifications. While this has facilitated aftermarket development, it presents concerns regarding emissions compliance and warranty validation. The absence of robust validation routines allows potentially damaging calibrations to be implemented without sufficient safeguards.

Software update mechanisms rely on specialized hardware interfaces and proprietary tools, complicating the deployment of improvements and patches. The absence of over-the-air update capabilities necessitates physical access to the vehicle for any software modifications, increasing maintenance costs and reducing the feasibility of regular updates to address emerging issues or optimize performance.

Contemporary LT1 Software Upgrade Methodologies

01 Engine Control Software Development

Software development methodologies and tools specifically designed for engine control systems, including the LT1 engine. These involve programming interfaces, debugging tools, and optimization techniques for engine performance parameters such as fuel injection, ignition timing, and emissions control. The software development process includes testing frameworks to ensure reliability and compliance with automotive standards.- Engine Control Software Development: Software development methodologies and tools specifically designed for engine control systems, including the LT1 engine. These involve programming techniques for optimizing engine performance, fuel efficiency, and emissions control. The software typically includes algorithms for managing ignition timing, fuel injection, and other critical engine parameters based on various sensor inputs and operating conditions.

- Software Update and Maintenance Systems: Systems and methods for updating and maintaining engine control software, including remote updates and diagnostic capabilities. These solutions enable software patches and improvements to be deployed to vehicle engine control units without requiring physical access to the vehicle. They also include version control systems and rollback capabilities to ensure system stability after updates.

- Engine Performance Optimization Software: Software solutions specifically designed to optimize the performance characteristics of engines, including tuning applications for the LT1 engine platform. These applications allow for customization of engine parameters to enhance power output, torque delivery, or fuel efficiency based on user preferences or specific driving conditions. The software may include real-time monitoring and adjustment capabilities.

- Diagnostic and Monitoring Software: Software tools for diagnosing engine issues, monitoring performance metrics, and analyzing data from the LT1 engine. These applications collect and process data from various engine sensors to identify potential problems, track performance trends, and provide insights for maintenance. They often include visualization tools and reporting capabilities to help interpret complex engine data.

- Integration with Vehicle Systems: Software solutions that enable integration between the engine control system and other vehicle systems, creating a comprehensive vehicle management platform. These solutions facilitate communication between the engine control unit and other electronic control units in the vehicle, allowing for coordinated operation of various systems such as transmission control, stability control, and infotainment systems.

02 Engine Diagnostic and Monitoring Systems

Software solutions for diagnosing and monitoring LT1 engine performance in real-time. These systems collect and analyze data from various engine sensors to detect anomalies, predict failures, and optimize performance. The diagnostic software provides interfaces for technicians to troubleshoot issues and perform maintenance tasks efficiently, while monitoring systems continuously track engine parameters during operation.Expand Specific Solutions03 Engine Software Update and Distribution

Methods and systems for updating and distributing software for engine control units, including those for LT1 engines. These solutions enable over-the-air updates, version management, and secure distribution of software patches and upgrades. The systems ensure compatibility with existing hardware and maintain engine performance while implementing new features or fixing issues in the control software.Expand Specific Solutions04 Engine Performance Optimization Software

Software applications designed to optimize the performance of LT1 engines through parameter tuning and calibration. These tools allow for customization of engine characteristics such as power output, fuel efficiency, and throttle response. The optimization software uses algorithms to analyze engine data and suggest or automatically implement adjustments to achieve desired performance characteristics.Expand Specific Solutions05 Integration with Vehicle Systems

Software solutions that enable integration of LT1 engine control systems with other vehicle systems such as transmission control, stability control, and infotainment systems. These integration platforms facilitate communication between different electronic control units (ECUs) in the vehicle, allowing for coordinated operation and enhanced overall vehicle performance. The software implements protocols for data exchange and synchronization between systems.Expand Specific Solutions

Major OEMs and ECU Software Providers Analysis

The LT1 engine software upgrade market is currently in a growth phase, with increasing demand driven by automotive digitalization trends. The competitive landscape is characterized by a mix of traditional automakers and emerging tech players. Established manufacturers like Mercedes-Benz, Geely, BYD, and Changan have strong positions due to their integrated vehicle systems expertise. Technology specialists including ZTE, Huawei-partnered Jinkang, and Xiaomi are disrupting the space with advanced software capabilities. The technology shows moderate maturity with companies like United Automotive Electronic Systems and Weichai Power offering specialized engine management solutions, while newer entrants like Jidu and Pateo are introducing innovative approaches to vehicle software architecture and over-the-air update capabilities.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed an advanced Engine Control Module (ECM) software upgrade system applicable to various engine types, including V8 engines with architecture similar to LT1. Their solution integrates cloud-based software distribution with on-board diagnostic capabilities, allowing for both dealership-based and limited over-the-air updates. The system employs a sophisticated version control mechanism that tracks all software changes and maintains compatibility with various vehicle subsystems. Geely's approach includes a proprietary calibration methodology that optimizes engine performance parameters while ensuring compliance with emissions regulations across different markets. Their upgrade process incorporates machine learning algorithms that analyze driving patterns and environmental conditions to fine-tune engine response characteristics, fuel efficiency, and emissions control. The system features a rollback capability that can restore previous software versions if anomalies are detected post-update.

Strengths: Integrated cloud-based distribution system; sophisticated version control; adaptive performance optimization based on usage patterns. Weaknesses: Limited full OTA capability for major engine management updates; requires dealer infrastructure for comprehensive updates; primarily designed for Geely's own engine architecture.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative hybrid approach to engine management software upgrades that could be applicable to V8 engines like the LT1. Their system combines traditional ECU updates with a supplementary control module that interfaces with the original engine management system, allowing for enhanced functionality without complete replacement of factory software. This dual-layer approach enables performance optimization while maintaining compatibility with original equipment diagnostics. BYD's solution incorporates a smartphone-based interface that provides users with basic diagnostic information and performance metrics, while more comprehensive updates are performed at service centers using their proprietary diagnostic equipment. Their software includes adaptive driving mode algorithms that can modify engine response characteristics based on driver preferences and usage patterns, with particular emphasis on optimizing the balance between performance and fuel efficiency. The system features a comprehensive logging capability that tracks engine parameters before and after updates to validate improvements.

Strengths: Innovative dual-layer approach preserves OEM compatibility; user-friendly interface with performance feedback; adaptive driving modes. Weaknesses: Limited full self-service capability; requires specialized equipment for comprehensive updates; primarily designed for integration with BYD's own powertrain systems.

Key Innovations in Engine Management Algorithms

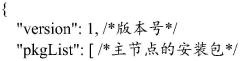

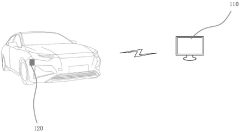

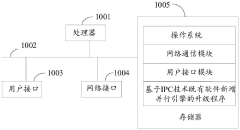

Software upgrading method and device, vehicle and storage medium

PatentPendingCN117950694A

Innovation

- By parsing the received installation package on the master node, the configuration file and image file are generated, and the installation package of the sub-node is sent to the corresponding sub-node to enable concurrent installation and improve software upgrade efficiency.

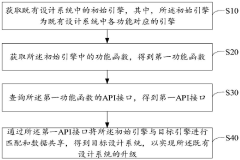

Upgrading method for newly-added parallel engine of existing software based on IPC technology

PatentPendingCN117632215A

Innovation

- By obtaining the initial engine in the existing design system, obtaining its functional functions and API interfaces, matching and data sharing with the target engine, the system is upgraded, and IPC technology is used for inter-process communication to achieve data sharing and rendering display.

Compliance with Emissions and Safety Regulations

Upgrading the LT1 engine software requires careful consideration of regulatory frameworks that govern vehicle emissions and safety standards. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) maintain strict emissions guidelines that any software modification must adhere to. These regulations establish specific thresholds for pollutants including nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Software upgrades that alter fuel mapping or ignition timing must ensure these emissions remain within legal limits across all operating conditions.

Federal Motor Vehicle Safety Standards (FMVSS) present another critical regulatory consideration, particularly regarding engine control systems that interface with safety features. Any software modification affecting throttle response, traction control, or stability management systems must maintain compliance with these standards. Manufacturers and aftermarket developers must validate that software changes do not compromise vehicle safety systems or create new safety risks.

On-Board Diagnostics (OBD-II) compliance represents a significant technical hurdle for LT1 software upgrades. The diagnostic system must continue to monitor emissions-related components effectively, with software modifications preserving all required monitoring functions. Tampering with or disabling these monitoring capabilities violates federal law and may trigger fault codes or inspection failures in regions with emissions testing programs.

The regulatory landscape varies significantly across different jurisdictions, with California and states following CARB standards implementing more stringent requirements than EPA federal minimums. Software developers must account for these regional variations to ensure their upgrades remain legal across all intended markets. International markets present additional complexity, with European Euro standards and other regional frameworks imposing their own unique requirements.

Testing and certification processes constitute a substantial investment for compliant software development. Dynamometer testing under standardized drive cycles is typically required to verify emissions compliance, while safety validation may necessitate extensive field testing under various operating conditions. Documentation of these testing protocols and results must be maintained to demonstrate due diligence in regulatory compliance.

Penalties for non-compliance can be severe, including substantial fines, mandatory recalls, and potential legal liability. The EPA has increasingly targeted aftermarket tuning companies offering non-compliant software modifications, with enforcement actions resulting in penalties exceeding millions of dollars in some cases. This regulatory enforcement trend underscores the importance of building compliance considerations into the earliest stages of LT1 software upgrade development.

Federal Motor Vehicle Safety Standards (FMVSS) present another critical regulatory consideration, particularly regarding engine control systems that interface with safety features. Any software modification affecting throttle response, traction control, or stability management systems must maintain compliance with these standards. Manufacturers and aftermarket developers must validate that software changes do not compromise vehicle safety systems or create new safety risks.

On-Board Diagnostics (OBD-II) compliance represents a significant technical hurdle for LT1 software upgrades. The diagnostic system must continue to monitor emissions-related components effectively, with software modifications preserving all required monitoring functions. Tampering with or disabling these monitoring capabilities violates federal law and may trigger fault codes or inspection failures in regions with emissions testing programs.

The regulatory landscape varies significantly across different jurisdictions, with California and states following CARB standards implementing more stringent requirements than EPA federal minimums. Software developers must account for these regional variations to ensure their upgrades remain legal across all intended markets. International markets present additional complexity, with European Euro standards and other regional frameworks imposing their own unique requirements.

Testing and certification processes constitute a substantial investment for compliant software development. Dynamometer testing under standardized drive cycles is typically required to verify emissions compliance, while safety validation may necessitate extensive field testing under various operating conditions. Documentation of these testing protocols and results must be maintained to demonstrate due diligence in regulatory compliance.

Penalties for non-compliance can be severe, including substantial fines, mandatory recalls, and potential legal liability. The EPA has increasingly targeted aftermarket tuning companies offering non-compliant software modifications, with enforcement actions resulting in penalties exceeding millions of dollars in some cases. This regulatory enforcement trend underscores the importance of building compliance considerations into the earliest stages of LT1 software upgrade development.

Performance Testing and Validation Protocols

Comprehensive performance testing and validation protocols are essential for any LT1 engine software upgrade to ensure reliability, safety, and optimal performance. The testing framework should begin with baseline measurements of the stock engine performance parameters, including horsepower, torque curves, fuel efficiency, emissions levels, and throttle response characteristics. These baseline metrics provide critical reference points against which all software modifications can be evaluated.

Dynamic testing protocols should incorporate both controlled laboratory environments and real-world driving conditions. Dynamometer testing allows for precise measurement of power output across the entire RPM range, while controlled road testing evaluates drivability, throttle response, and cold/hot start behavior. Environmental chamber testing is crucial to validate software performance across extreme temperature ranges from -20°F to 120°F, ensuring the upgrade functions reliably in all climates.

Durability validation requires extended testing cycles, typically involving 500+ hours of operation under varying load conditions. This includes sustained high-RPM testing, thermal cycling, and simulated aggressive driving patterns to stress-test the software's ability to maintain engine protection parameters. Particular attention should be paid to monitoring knock sensor response, fuel trim adaptations, and thermal management strategies during these extended tests.

Emissions compliance testing must follow standardized protocols such as the Federal Test Procedure (FTP) and Supplemental Federal Test Procedure (SFTP) to ensure the upgraded software maintains compliance with relevant EPA and CARB standards. This includes cold-start emissions, highway driving cycles, and aggressive driving scenarios to comprehensively evaluate the emissions profile under all operating conditions.

Diagnostic functionality validation is another critical component, requiring verification that all OBD-II systems continue to function properly with the upgraded software. This includes confirming proper operation of fault detection algorithms, sensor range checking, and communication protocols between the ECU and diagnostic equipment.

Final validation should include comparative A/B testing between stock and upgraded software configurations across multiple identical test vehicles to establish statistical confidence in performance improvements. Data logging during these tests should capture comprehensive metrics including air/fuel ratios, ignition timing, variable valve timing positions, and exhaust gas temperatures to ensure all systems operate within safe parameters while delivering the intended performance gains.

Dynamic testing protocols should incorporate both controlled laboratory environments and real-world driving conditions. Dynamometer testing allows for precise measurement of power output across the entire RPM range, while controlled road testing evaluates drivability, throttle response, and cold/hot start behavior. Environmental chamber testing is crucial to validate software performance across extreme temperature ranges from -20°F to 120°F, ensuring the upgrade functions reliably in all climates.

Durability validation requires extended testing cycles, typically involving 500+ hours of operation under varying load conditions. This includes sustained high-RPM testing, thermal cycling, and simulated aggressive driving patterns to stress-test the software's ability to maintain engine protection parameters. Particular attention should be paid to monitoring knock sensor response, fuel trim adaptations, and thermal management strategies during these extended tests.

Emissions compliance testing must follow standardized protocols such as the Federal Test Procedure (FTP) and Supplemental Federal Test Procedure (SFTP) to ensure the upgraded software maintains compliance with relevant EPA and CARB standards. This includes cold-start emissions, highway driving cycles, and aggressive driving scenarios to comprehensively evaluate the emissions profile under all operating conditions.

Diagnostic functionality validation is another critical component, requiring verification that all OBD-II systems continue to function properly with the upgraded software. This includes confirming proper operation of fault detection algorithms, sensor range checking, and communication protocols between the ECU and diagnostic equipment.

Final validation should include comparative A/B testing between stock and upgraded software configurations across multiple identical test vehicles to establish statistical confidence in performance improvements. Data logging during these tests should capture comprehensive metrics including air/fuel ratios, ignition timing, variable valve timing positions, and exhaust gas temperatures to ensure all systems operate within safe parameters while delivering the intended performance gains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!