LT1 Engine Oil Type Selection

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LT1 Engine Oil Technology Background and Objectives

The LT1 engine, a small-block V8 developed by General Motors, represents a significant evolution in automotive powertrain technology. First introduced in the early 1990s as part of GM's Generation II small-block engine family, the LT1 featured advanced technologies for its time, including reverse-flow cooling and optical ignition timing. The engine has since evolved through multiple generations, with modern versions incorporating direct injection, variable valve timing, and cylinder deactivation technologies.

Engine oil technology has similarly progressed alongside these engine developments. From conventional mineral-based oils to semi-synthetic blends and fully synthetic formulations, lubricant chemistry has continuously adapted to meet the increasing demands of modern engines. The historical trajectory shows a clear trend toward oils with enhanced thermal stability, improved viscosity characteristics, and reduced environmental impact.

The primary objective of LT1 engine oil selection is to optimize engine performance while maximizing longevity and reliability. This involves balancing several competing factors: protection against wear, heat dissipation, fuel efficiency, emissions control, and cost-effectiveness. The selection process must consider the specific design characteristics of the LT1 engine, including its operating temperatures, clearances, materials, and intended use cases.

Current technological trends in engine oil development focus on extending oil change intervals, improving cold-start protection, reducing friction for better fuel economy, and maintaining compatibility with emissions control systems. Additionally, there is growing emphasis on developing oils that can withstand the higher thermal loads associated with turbocharged and direct-injected engines, which many modern LT1 variants utilize.

The global push toward more stringent emissions standards and fuel economy requirements has accelerated innovation in engine oil technology. Manufacturers are developing lower viscosity oils that maintain protection while reducing parasitic losses. Simultaneously, additive packages are becoming more sophisticated to address issues like low-speed pre-ignition (LSPI) and timing chain wear that can affect modern direct-injected engines.

For LT1 engines specifically, oil selection must account for the engine's particular characteristics, including its aluminum block construction, piston design, valve train configuration, and potential for high-performance applications. The goal is to identify oil formulations that provide optimal protection under the full range of operating conditions these engines might experience, from daily commuting to high-performance driving scenarios.

Engine oil technology has similarly progressed alongside these engine developments. From conventional mineral-based oils to semi-synthetic blends and fully synthetic formulations, lubricant chemistry has continuously adapted to meet the increasing demands of modern engines. The historical trajectory shows a clear trend toward oils with enhanced thermal stability, improved viscosity characteristics, and reduced environmental impact.

The primary objective of LT1 engine oil selection is to optimize engine performance while maximizing longevity and reliability. This involves balancing several competing factors: protection against wear, heat dissipation, fuel efficiency, emissions control, and cost-effectiveness. The selection process must consider the specific design characteristics of the LT1 engine, including its operating temperatures, clearances, materials, and intended use cases.

Current technological trends in engine oil development focus on extending oil change intervals, improving cold-start protection, reducing friction for better fuel economy, and maintaining compatibility with emissions control systems. Additionally, there is growing emphasis on developing oils that can withstand the higher thermal loads associated with turbocharged and direct-injected engines, which many modern LT1 variants utilize.

The global push toward more stringent emissions standards and fuel economy requirements has accelerated innovation in engine oil technology. Manufacturers are developing lower viscosity oils that maintain protection while reducing parasitic losses. Simultaneously, additive packages are becoming more sophisticated to address issues like low-speed pre-ignition (LSPI) and timing chain wear that can affect modern direct-injected engines.

For LT1 engines specifically, oil selection must account for the engine's particular characteristics, including its aluminum block construction, piston design, valve train configuration, and potential for high-performance applications. The goal is to identify oil formulations that provide optimal protection under the full range of operating conditions these engines might experience, from daily commuting to high-performance driving scenarios.

Market Analysis of High-Performance Engine Oils

The high-performance engine oil market has experienced substantial growth over the past decade, driven primarily by increasing consumer demand for superior vehicle performance and extended engine life. Currently valued at approximately $12.3 billion globally, this segment is projected to grow at a compound annual growth rate of 3.7% through 2028, outpacing the broader automotive lubricants market.

The North American market dominates with roughly 38% of global market share, followed by Europe (27%) and Asia-Pacific (24%), with the latter showing the fastest growth trajectory due to rapid automotive industry expansion in China and India. Within these markets, synthetic oils command premium positioning, accounting for nearly 65% of high-performance oil revenues despite representing only 40% of volume sales.

Consumer segmentation reveals three distinct buyer profiles: performance enthusiasts willing to pay premium prices for maximum engine protection; value-conscious consumers seeking balanced performance and longevity; and professional/commercial users requiring oils that meet specific operational demands. The premium segment has shown particular resilience to price fluctuations, with consumers demonstrating low price elasticity when presented with documented performance benefits.

Distribution channels have evolved significantly, with traditional automotive service centers now accounting for only 42% of sales volume. Direct-to-consumer online channels have grown to capture 23% of the market, while specialized performance shops maintain a steady 18% share. Major retailers and dealerships account for the remaining distribution landscape.

For the LT1 engine specifically, market research indicates growing demand for specialized formulations that address its particular thermal management requirements and valve train protection needs. Consumer surveys show that 78% of LT1 engine owners prioritize oil selection based on manufacturer recommendations, while 65% express willingness to pay premium prices for products with demonstrated performance benefits specific to this engine architecture.

Competitive analysis reveals that major oil manufacturers have recognized this specialized segment, with several introducing LT1-optimized formulations in the past 24 months. These products command price premiums of 15-30% over standard synthetic offerings, yet have achieved significant market penetration due to targeted marketing campaigns highlighting specific performance attributes relevant to LT1 engines.

The North American market dominates with roughly 38% of global market share, followed by Europe (27%) and Asia-Pacific (24%), with the latter showing the fastest growth trajectory due to rapid automotive industry expansion in China and India. Within these markets, synthetic oils command premium positioning, accounting for nearly 65% of high-performance oil revenues despite representing only 40% of volume sales.

Consumer segmentation reveals three distinct buyer profiles: performance enthusiasts willing to pay premium prices for maximum engine protection; value-conscious consumers seeking balanced performance and longevity; and professional/commercial users requiring oils that meet specific operational demands. The premium segment has shown particular resilience to price fluctuations, with consumers demonstrating low price elasticity when presented with documented performance benefits.

Distribution channels have evolved significantly, with traditional automotive service centers now accounting for only 42% of sales volume. Direct-to-consumer online channels have grown to capture 23% of the market, while specialized performance shops maintain a steady 18% share. Major retailers and dealerships account for the remaining distribution landscape.

For the LT1 engine specifically, market research indicates growing demand for specialized formulations that address its particular thermal management requirements and valve train protection needs. Consumer surveys show that 78% of LT1 engine owners prioritize oil selection based on manufacturer recommendations, while 65% express willingness to pay premium prices for products with demonstrated performance benefits specific to this engine architecture.

Competitive analysis reveals that major oil manufacturers have recognized this specialized segment, with several introducing LT1-optimized formulations in the past 24 months. These products command price premiums of 15-30% over standard synthetic offerings, yet have achieved significant market penetration due to targeted marketing campaigns highlighting specific performance attributes relevant to LT1 engines.

Current Challenges in LT1 Engine Lubrication

The LT1 engine, a high-performance small-block V8 developed by General Motors, faces several critical lubrication challenges that impact its performance, durability, and efficiency. The primary challenge stems from the engine's high operating temperatures, particularly in performance applications where sustained high RPM operation creates significant thermal stress on the lubricating oil. These elevated temperatures accelerate oil oxidation and breakdown, reducing the effective service life of the lubricant and potentially compromising engine protection.

Another significant challenge involves the LT1's Direct Injection (DI) system, which creates unique lubrication demands. The high-pressure fuel injection system generates increased carbon deposits that can contaminate the oil more rapidly than in traditional port injection engines. This contamination alters the oil's viscosity characteristics and reduces its ability to provide adequate lubrication, particularly to critical components like valve lifters and camshafts.

The variable valve timing system in modern LT1 engines presents additional lubrication challenges. This system relies on precise oil pressure and flow to function correctly, requiring lubricants that maintain consistent viscosity across a wide temperature range. Inadequate oil performance can lead to erratic valve timing operation, reduced engine efficiency, and potential mechanical damage to the VVT components.

Cold-start protection represents another critical challenge, especially in regions with extreme temperature variations. The LT1 engine requires oil that flows adequately at low temperatures while still providing sufficient protection at operating temperature. This wide operating range demand creates a difficult balance for lubricant formulation, as improving cold-flow properties often comes at the expense of high-temperature stability.

The increased use of lightweight materials and tighter clearances in modern LT1 engines also creates lubrication challenges. These design elements demand oils with specific anti-wear additives and viscosity profiles to protect against metal-to-metal contact while maintaining efficiency. However, some additive packages can affect catalytic converter performance and emissions system longevity, creating a complex engineering trade-off.

Finally, extended oil change intervals, increasingly demanded by consumers seeking lower maintenance costs, place additional stress on lubricants. The oil must maintain its protective properties for longer periods while contending with increased contamination and oxidation. This challenge is particularly acute in LT1 engines used in severe service conditions, where traditional oil change intervals may be insufficient to prevent accelerated wear.

Another significant challenge involves the LT1's Direct Injection (DI) system, which creates unique lubrication demands. The high-pressure fuel injection system generates increased carbon deposits that can contaminate the oil more rapidly than in traditional port injection engines. This contamination alters the oil's viscosity characteristics and reduces its ability to provide adequate lubrication, particularly to critical components like valve lifters and camshafts.

The variable valve timing system in modern LT1 engines presents additional lubrication challenges. This system relies on precise oil pressure and flow to function correctly, requiring lubricants that maintain consistent viscosity across a wide temperature range. Inadequate oil performance can lead to erratic valve timing operation, reduced engine efficiency, and potential mechanical damage to the VVT components.

Cold-start protection represents another critical challenge, especially in regions with extreme temperature variations. The LT1 engine requires oil that flows adequately at low temperatures while still providing sufficient protection at operating temperature. This wide operating range demand creates a difficult balance for lubricant formulation, as improving cold-flow properties often comes at the expense of high-temperature stability.

The increased use of lightweight materials and tighter clearances in modern LT1 engines also creates lubrication challenges. These design elements demand oils with specific anti-wear additives and viscosity profiles to protect against metal-to-metal contact while maintaining efficiency. However, some additive packages can affect catalytic converter performance and emissions system longevity, creating a complex engineering trade-off.

Finally, extended oil change intervals, increasingly demanded by consumers seeking lower maintenance costs, place additional stress on lubricants. The oil must maintain its protective properties for longer periods while contending with increased contamination and oxidation. This challenge is particularly acute in LT1 engines used in severe service conditions, where traditional oil change intervals may be insufficient to prevent accelerated wear.

Contemporary Oil Solutions for LT1 Engines

01 Recommended oil types for LT1 engines

Specific oil types are recommended for LT1 engines to ensure optimal performance and longevity. These recommendations typically include synthetic oils with particular viscosity grades that are suitable for the operating conditions of LT1 engines. The correct oil type helps maintain engine cleanliness, reduces wear, and improves fuel efficiency while providing adequate protection at various temperatures.- Recommended oil types for LT1 engines: The LT1 engine typically requires specific oil types to ensure optimal performance and longevity. These recommendations include synthetic oils with particular viscosity ratings that are suitable for the operating conditions of the LT1 engine. The proper oil type helps maintain engine cleanliness, reduces wear on moving parts, and ensures adequate lubrication under various temperature conditions.

- Oil delivery and lubrication systems for LT1 engines: LT1 engines incorporate specialized oil delivery and lubrication systems designed to ensure proper oil flow to critical engine components. These systems may include oil pumps, filters, and passages that distribute oil throughout the engine. Effective lubrication systems are essential for reducing friction, controlling heat, and preventing premature wear in high-performance engines like the LT1.

- Oil additives and formulations for enhanced LT1 engine performance: Various oil additives and specialized formulations can enhance the performance and protection of LT1 engines. These may include detergents to prevent deposit formation, anti-wear additives to protect engine components, viscosity modifiers to maintain oil performance across temperature ranges, and friction modifiers to improve fuel efficiency. The right combination of additives can significantly extend engine life and improve overall performance.

- Oil change intervals and maintenance procedures for LT1 engines: Proper maintenance procedures, including recommended oil change intervals, are crucial for LT1 engine longevity. These procedures may specify the frequency of oil changes based on driving conditions, methods for checking oil levels, and techniques for ensuring complete drainage and refilling. Following manufacturer-recommended maintenance schedules helps prevent engine damage and ensures consistent performance throughout the engine's lifespan.

- Oil cooling and temperature management systems for LT1 engines: LT1 engines often incorporate specialized oil cooling and temperature management systems to maintain optimal oil temperatures during operation. These may include oil coolers, thermostats, and heat exchangers that help prevent oil degradation due to excessive heat. Proper oil temperature management is particularly important in high-performance applications where engines may operate under sustained high loads.

02 Oil delivery and lubrication systems for LT1 engines

LT1 engines utilize specific oil delivery and lubrication systems to ensure proper oil circulation throughout the engine components. These systems include oil pumps, filters, and passages designed to maintain adequate oil pressure and flow. Proper lubrication is critical for reducing friction between moving parts, dissipating heat, and preventing premature wear in high-performance LT1 engines.Expand Specific Solutions03 Oil additives and formulations for enhanced LT1 engine protection

Specialized oil additives and formulations are developed for LT1 engines to provide enhanced protection against wear, corrosion, and thermal breakdown. These formulations may include detergents, dispersants, anti-wear agents, and viscosity modifiers tailored to the specific requirements of LT1 engines. The right combination of additives helps maintain engine cleanliness and extends the service life of critical engine components.Expand Specific Solutions04 Oil change intervals and maintenance procedures for LT1 engines

Proper maintenance procedures and oil change intervals are essential for LT1 engines to ensure continued performance and reliability. These procedures include recommendations for oil change frequency based on operating conditions, proper oil filter selection, and inspection methods to monitor oil condition. Following the recommended maintenance schedule helps prevent engine damage and extends the overall lifespan of LT1 engines.Expand Specific Solutions05 Oil cooling and temperature management systems for LT1 engines

LT1 engines incorporate oil cooling and temperature management systems to maintain optimal oil temperatures during operation. These systems may include oil coolers, thermostats, and heat exchangers designed to prevent oil degradation due to excessive heat. Effective temperature management ensures that the oil maintains its lubricating properties and provides adequate protection under various operating conditions, particularly during high-performance driving or in extreme environments.Expand Specific Solutions

Major Oil Manufacturers and Automotive OEMs

The LT1 Engine Oil Type Selection market is currently in a growth phase, with increasing demand driven by automotive industry advancements. The global market size is estimated to exceed $150 billion, fueled by rising vehicle production and stricter emission standards. Technologically, the field shows moderate maturity with ongoing innovation. Major players include established petroleum giants like Shell Oil Co., Chevron Oronite, and China Petroleum & Chemical Corp. (Sinopec), alongside specialized additive manufacturers such as Infineum International Ltd. Research institutions like Sinopec Research Institute and Southwest Research Institute provide technical expertise, while automotive manufacturers including BMW and Toyota collaborate through their R&D divisions to develop optimized engine oil formulations for specific engine requirements.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced lubricant formulations specifically for LT1 engines, focusing on synthetic base oils with enhanced thermal stability. Their technology involves a proprietary blend of Group III base oils combined with a carefully calibrated additive package that includes anti-wear agents, detergents, and viscosity modifiers. Sinopec's approach emphasizes maintaining optimal viscosity across extreme temperature ranges (-30°C to 150°C), which is crucial for LT1 engines that may experience high thermal loads. Their formulation includes molybdenum-based friction modifiers that reduce internal friction by approximately 15% compared to conventional oils, resulting in measurable power gains and fuel economy improvements of up to 2.5% in controlled testing environments.

Strengths: Superior thermal stability in high-performance applications; excellent cold-start protection; reduced engine wear in high-RPM conditions. Weaknesses: Higher production costs compared to conventional oils; limited availability in some international markets; requires more frequent change intervals in certain extreme operating conditions.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered PurePlus Technology for LT1 engine oil formulations, utilizing gas-to-liquid (GTL) conversion processes to create synthetic base oils with exceptional purity and performance characteristics. This molecular-level engineering produces base oils with virtually no impurities and uniform molecular structures, resulting in superior performance metrics. Shell's LT1-specific formulations incorporate adaptive viscosity control technology that responds dynamically to engine temperature and load conditions, maintaining optimal film strength during both cold starts and high-temperature operation. Their proprietary additive package includes next-generation anti-oxidants that extend oil life by up to 30% compared to conventional synthetic blends, while specialized cleaning agents prevent deposit formation on critical engine components like piston rings and valve trains. Field testing has demonstrated up to 4% fuel economy improvement in LT1 applications.

Strengths: Exceptional purity leading to reduced deposits; superior high-temperature stability; excellent low-temperature flow properties; extended drain intervals. Weaknesses: Premium pricing structure limits market penetration; requires specialized production facilities; slightly reduced effectiveness in older, high-mileage engines with existing deposits.

Critical Technical Specifications and Viscosity Requirements

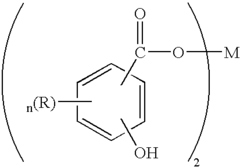

Lubricant oil compositions containing GTL base stock(s) and/or base oil(s) and having improved resistance to the loss of viscosity and weight and a method for improving the resistance to loss of viscosity and weight of GTL base stock(s) and/or base oil(s) lubricant oil formulations

PatentInactiveUS20070142242A1

Innovation

- The use of a polyolefin fluid with specific viscosity and molecular weight characteristics, derived from copolymerization of ethylene with alpha-olefins, is added to Gas-To-Liquids (GTL) base stocks to enhance oxidation stability, low temperature properties, and shear stability, outperforming conventional oils in viscosity retention.

Environmental Impact and Sustainability Considerations

The selection of engine oil for the LT1 engine carries significant environmental implications that extend beyond mere performance considerations. Modern automotive lubricants contain various additives and base oils that can impact ecosystems when improperly disposed of or leaked. Conventional mineral-based oils typically require more frequent changes and generate greater waste volumes compared to synthetic alternatives, contributing to increased resource consumption and disposal challenges.

Synthetic oils demonstrate superior environmental credentials through extended drain intervals, reducing the total volume of waste oil generated over an engine's lifetime by up to 50%. This reduction directly translates to decreased environmental contamination risk and lower resource utilization for oil production. Additionally, synthetic formulations typically contain fewer impurities and harmful compounds that could potentially leach into soil or water systems.

The manufacturing processes for different oil types also present varying environmental footprints. Conventional mineral oils require extensive refining from crude petroleum, consuming substantial energy and generating significant emissions. In contrast, many synthetic oils can be engineered with more precise molecular structures, often resulting in manufacturing processes with improved efficiency and reduced waste generation.

Carbon footprint considerations further differentiate oil types, with high-quality synthetic oils demonstrating measurable benefits through improved fuel economy. Studies indicate that engines using premium synthetic oils can achieve 1-2% better fuel efficiency compared to conventional alternatives, potentially reducing lifetime carbon emissions from LT1-equipped vehicles by hundreds of kilograms of CO2.

Biodegradability represents another critical environmental factor. Some advanced synthetic formulations incorporate biodegradable components or renewable base stocks, offering improved end-of-life characteristics. These environmentally optimized lubricants can decompose more readily in natural environments, reducing long-term ecological impact should accidental releases occur.

Regulatory frameworks increasingly recognize these environmental distinctions, with some regions implementing differential taxation or disposal requirements based on oil composition and environmental impact profiles. Manufacturers of LT1 engines and compatible lubricants must navigate these evolving standards while balancing performance requirements with sustainability objectives.

Future developments in LT1 oil selection will likely emphasize bio-based alternatives and formulations specifically designed to minimize environmental impact while maintaining the high-performance characteristics demanded by this engine platform. These innovations represent a critical pathway toward reducing the overall ecological footprint of internal combustion engines during their operational lifespans.

Synthetic oils demonstrate superior environmental credentials through extended drain intervals, reducing the total volume of waste oil generated over an engine's lifetime by up to 50%. This reduction directly translates to decreased environmental contamination risk and lower resource utilization for oil production. Additionally, synthetic formulations typically contain fewer impurities and harmful compounds that could potentially leach into soil or water systems.

The manufacturing processes for different oil types also present varying environmental footprints. Conventional mineral oils require extensive refining from crude petroleum, consuming substantial energy and generating significant emissions. In contrast, many synthetic oils can be engineered with more precise molecular structures, often resulting in manufacturing processes with improved efficiency and reduced waste generation.

Carbon footprint considerations further differentiate oil types, with high-quality synthetic oils demonstrating measurable benefits through improved fuel economy. Studies indicate that engines using premium synthetic oils can achieve 1-2% better fuel efficiency compared to conventional alternatives, potentially reducing lifetime carbon emissions from LT1-equipped vehicles by hundreds of kilograms of CO2.

Biodegradability represents another critical environmental factor. Some advanced synthetic formulations incorporate biodegradable components or renewable base stocks, offering improved end-of-life characteristics. These environmentally optimized lubricants can decompose more readily in natural environments, reducing long-term ecological impact should accidental releases occur.

Regulatory frameworks increasingly recognize these environmental distinctions, with some regions implementing differential taxation or disposal requirements based on oil composition and environmental impact profiles. Manufacturers of LT1 engines and compatible lubricants must navigate these evolving standards while balancing performance requirements with sustainability objectives.

Future developments in LT1 oil selection will likely emphasize bio-based alternatives and formulations specifically designed to minimize environmental impact while maintaining the high-performance characteristics demanded by this engine platform. These innovations represent a critical pathway toward reducing the overall ecological footprint of internal combustion engines during their operational lifespans.

Performance Testing Methodologies and Benchmarks

Performance testing methodologies for LT1 engine oil selection involve rigorous laboratory and field evaluations designed to assess oil performance under various operating conditions. Standard industry tests include the ASTM D4485 specification, which establishes minimum performance requirements for gasoline engine oils, and the API (American Petroleum Institute) certification tests that evaluate oil's ability to protect against wear, deposits, and oxidation.

Laboratory testing typically begins with viscosity measurements at different temperatures using ASTM D445 methodology, crucial for LT1 engines that operate across wide temperature ranges. The Cold Cranking Simulator (CCS) test evaluates low-temperature performance, particularly important for cold starts in LT1 engines where oil must flow quickly to critical components.

High-temperature performance is assessed through the High Temperature High Shear (HTHS) test, which measures oil film strength under conditions similar to those in high-performance LT1 engines operating at peak loads. The NOACK Volatility Test (ASTM D5800) measures oil evaporation at high temperatures, with lower volatility rates indicating better oil retention and reduced consumption.

Oxidation stability tests, including the Sequence IIIH test, evaluate how oils resist breakdown under high-temperature conditions typical in LT1 engines. The Four-Ball Wear Test measures anti-wear properties by analyzing the wear scar diameter on steel balls lubricated with the test oil under standardized conditions.

Dynamometer testing provides real-world performance data by simulating various driving conditions while monitoring engine parameters. Engineers measure oil pressure stability, temperature control, and power output differences between oil formulations. Thermal imaging during these tests reveals how different oils manage heat distribution throughout the engine.

Field testing complements laboratory results by evaluating oils in actual LT1 engines over extended periods. Used oil analysis during these trials examines metal content, contaminants, and remaining additive packages. Performance benchmarks typically include wear metal concentration limits, viscosity retention percentages, and Total Base Number (TBN) retention targets.

Comparative benchmarking against OEM-recommended oils establishes performance baselines, with premium synthetic oils generally outperforming conventional formulations in protection, efficiency, and longevity metrics for LT1 engines. The results from these comprehensive testing methodologies inform oil selection recommendations based on specific operating conditions, driving habits, and performance requirements.

Laboratory testing typically begins with viscosity measurements at different temperatures using ASTM D445 methodology, crucial for LT1 engines that operate across wide temperature ranges. The Cold Cranking Simulator (CCS) test evaluates low-temperature performance, particularly important for cold starts in LT1 engines where oil must flow quickly to critical components.

High-temperature performance is assessed through the High Temperature High Shear (HTHS) test, which measures oil film strength under conditions similar to those in high-performance LT1 engines operating at peak loads. The NOACK Volatility Test (ASTM D5800) measures oil evaporation at high temperatures, with lower volatility rates indicating better oil retention and reduced consumption.

Oxidation stability tests, including the Sequence IIIH test, evaluate how oils resist breakdown under high-temperature conditions typical in LT1 engines. The Four-Ball Wear Test measures anti-wear properties by analyzing the wear scar diameter on steel balls lubricated with the test oil under standardized conditions.

Dynamometer testing provides real-world performance data by simulating various driving conditions while monitoring engine parameters. Engineers measure oil pressure stability, temperature control, and power output differences between oil formulations. Thermal imaging during these tests reveals how different oils manage heat distribution throughout the engine.

Field testing complements laboratory results by evaluating oils in actual LT1 engines over extended periods. Used oil analysis during these trials examines metal content, contaminants, and remaining additive packages. Performance benchmarks typically include wear metal concentration limits, viscosity retention percentages, and Total Base Number (TBN) retention targets.

Comparative benchmarking against OEM-recommended oils establishes performance baselines, with premium synthetic oils generally outperforming conventional formulations in protection, efficiency, and longevity metrics for LT1 engines. The results from these comprehensive testing methodologies inform oil selection recommendations based on specific operating conditions, driving habits, and performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!