Jack shaft garage door operator

a technology of operator and shaft, which is applied in the direction of door/window fittings, building braking devices, construction, etc., can solve the problems of cable dropping, cable coming off the drum, shaft garage door operator does not provide any secure locking facility, etc., and achieves the effect of reducing tension and preventing further upward motion of the garage door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

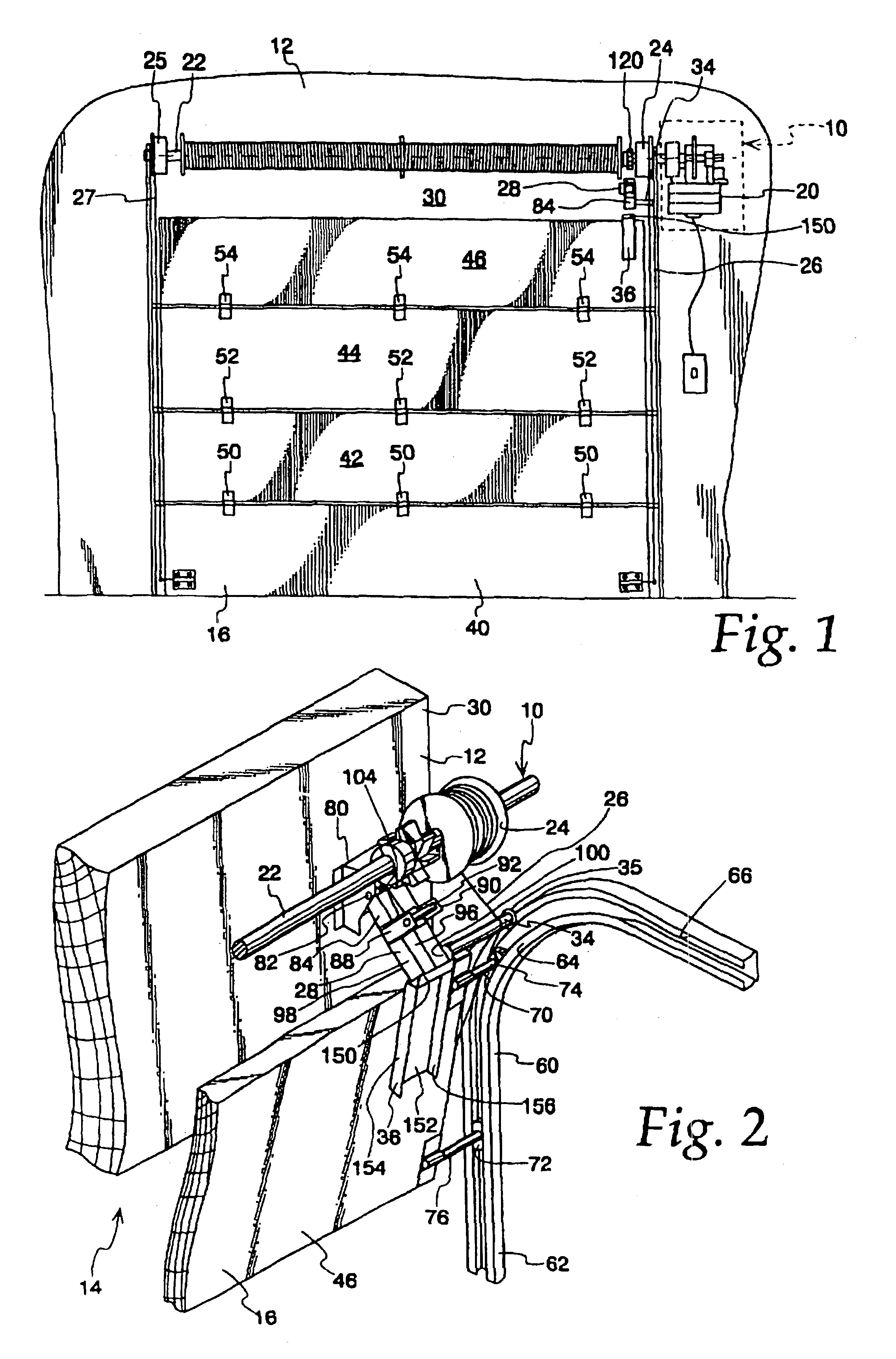

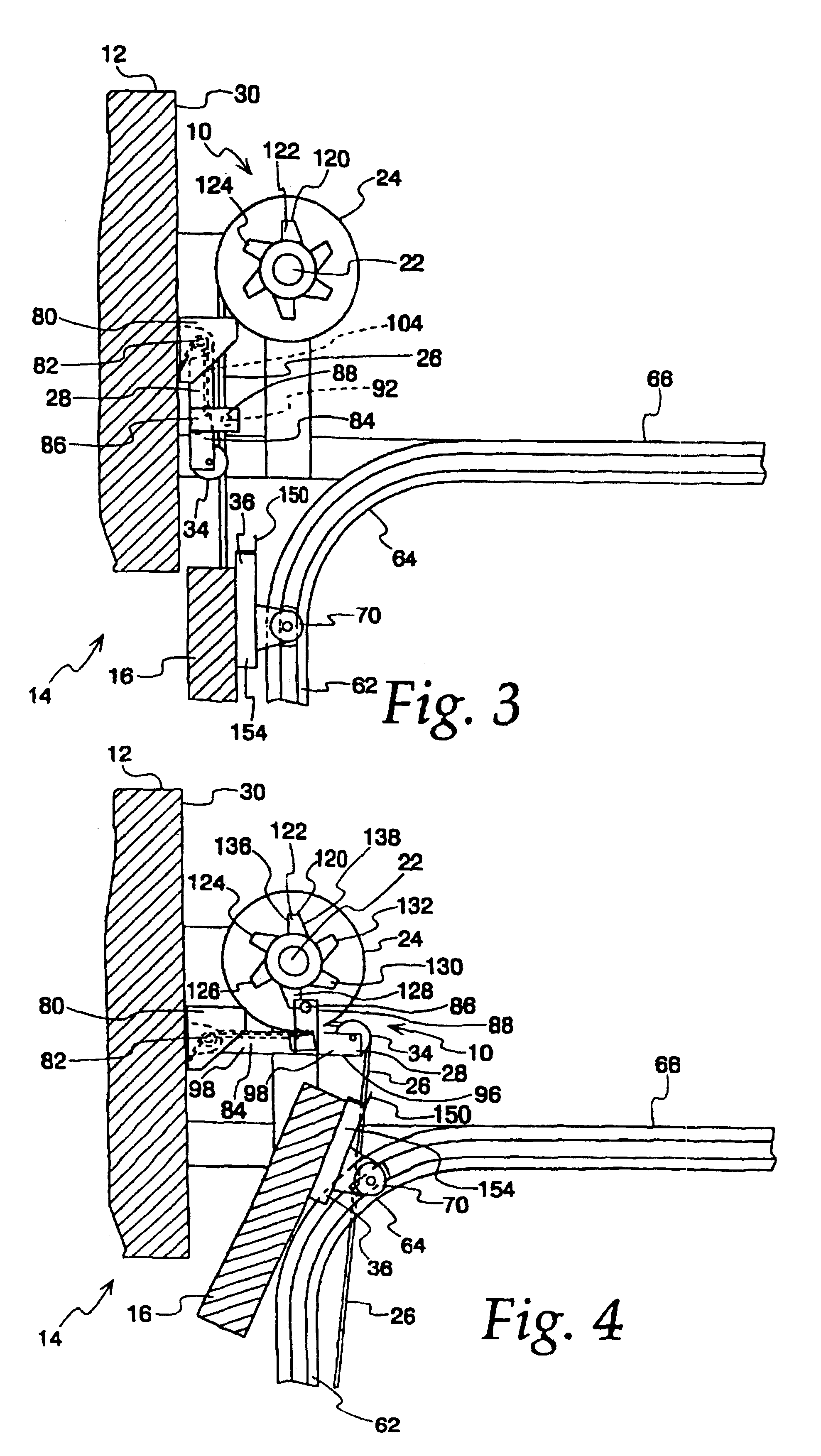

[0019]Referring now to the drawings and especially to FIG. 1, a jack shaft garage door operator embodying the present invention and generally identified by numeral 10 is shown therein. The jack shaft garage door operator 10 is mounted on a garage 12 near a garage door opening 14 which has associated with it a movable multiple panel garage door 16.

[0020]The jack shaft garage door operator 10 includes a drive unit 20 having a jack shaft 22 coupled thereto to be turned thereby. A pull-up cable unit 24 is mounted on the jack shaft 22 to be turned and a pull-up cable 26 is wound around the cable drum 24 to be pulled upwardly. A pivotable arm assembly 28 is mounted on a header 30 of the garage 12 immediately above the door opening 14 adjacent the jack shaft 22 and includes a cylindrical cable engaging member or cable tensioner arm 34 for engaging the pull-up cable 26 and ending in a cable retaining knob 35 for preventing the pull-up cable 26 from sliding off the tensioner arm 34. A door l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com