Apparatus for dispensing a quantity of material on a shell

a technology of a shell and a quantity of material, applied in the direction of sweetmeat, food preparation, food shaping, etc., can solve the problems of unfavorable pizza production, unfavorable pizza production, and inability to accurately produce individual frozen pizzas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail a preferred embodiment of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiment illustrated.

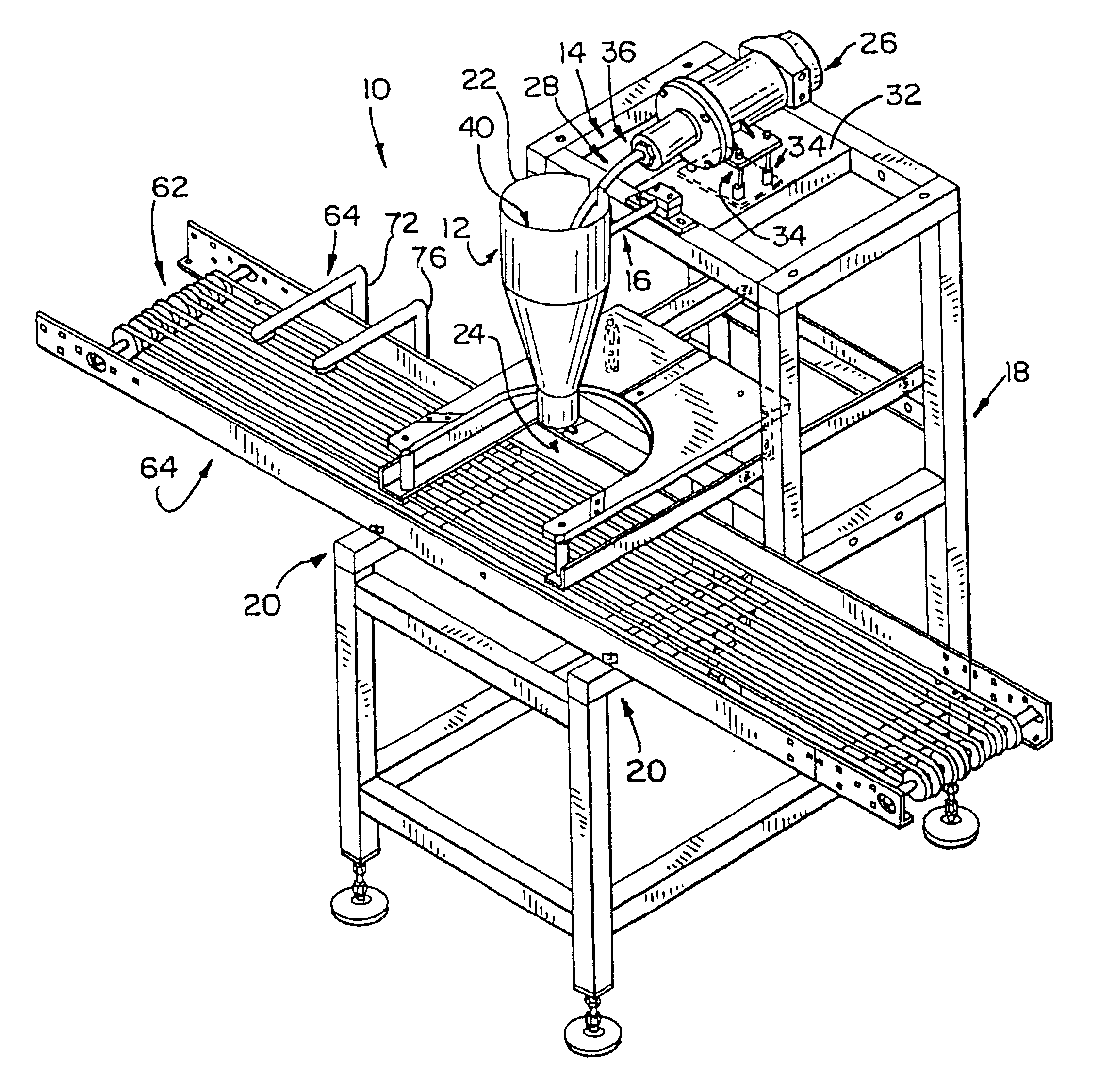

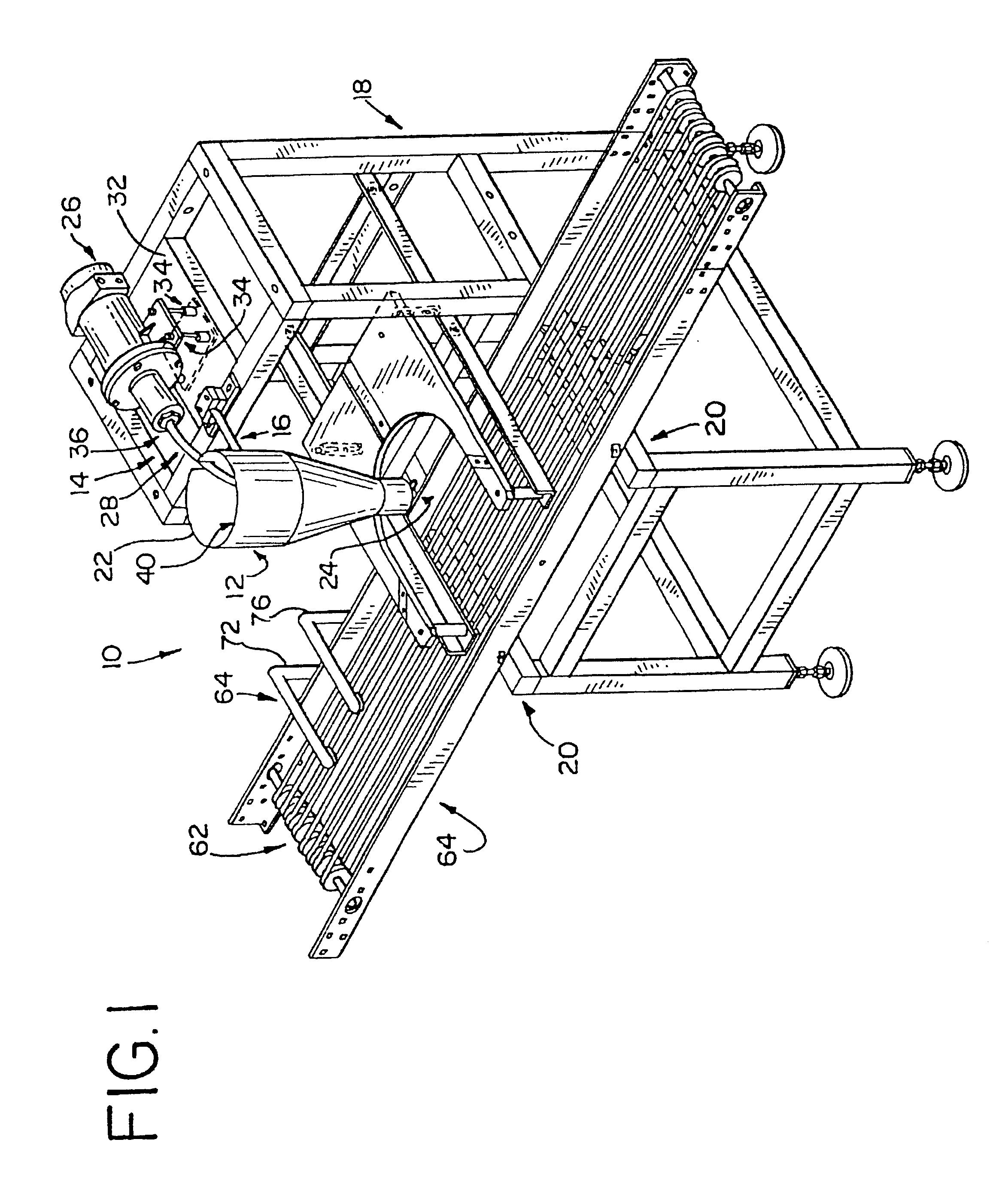

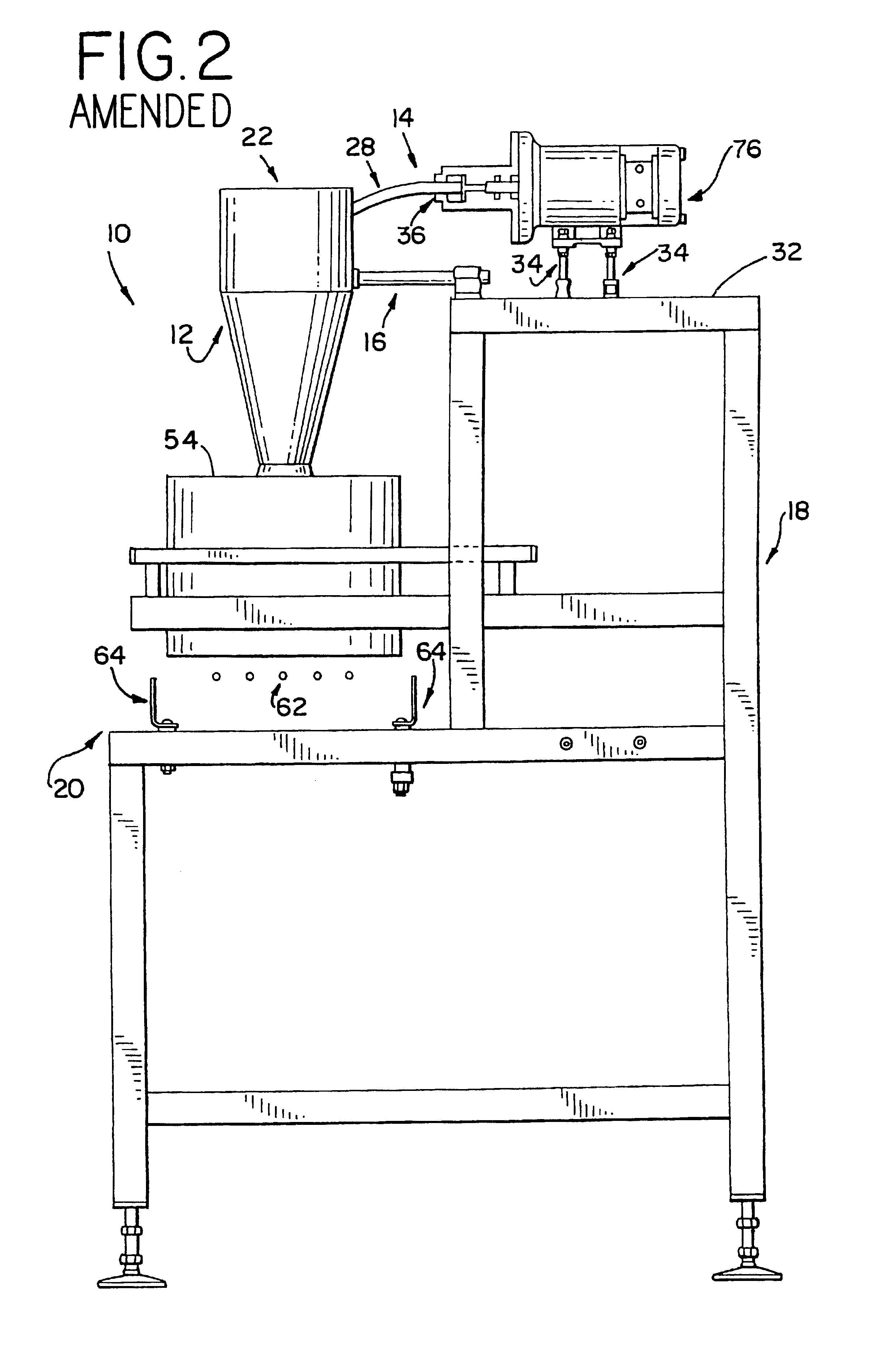

FIG. 1 is a perspective view of a food material dispensing apparatus 10 of the present invention. The food material dispensing apparatus dispenses a food material to a plurality of .Iadd.sequenced .Iaddend.target locations. The target locations can .Iadd.each .Iaddend.be a target food of a type that requires additional toppings. In the preferred embodiment, the target foods are pizza shells or crusts used in the frozen pizza field and the food material is a cheese topping. The dispensing apparatus .[.comprises.]. .Iadd.includes .Iaddend.a hopper 12 and a food distributing system 14.

I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com