Universal case lube tray

a lubricating tray and universal technology, applied in the direction of weapons, ammunition, weapon components, etc., can solve the problems of not all cases are equally and thoroughly lubricated, dissolving and diluting gunpowder, and reducing the efficiency and effectiveness of lubricating firearm cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

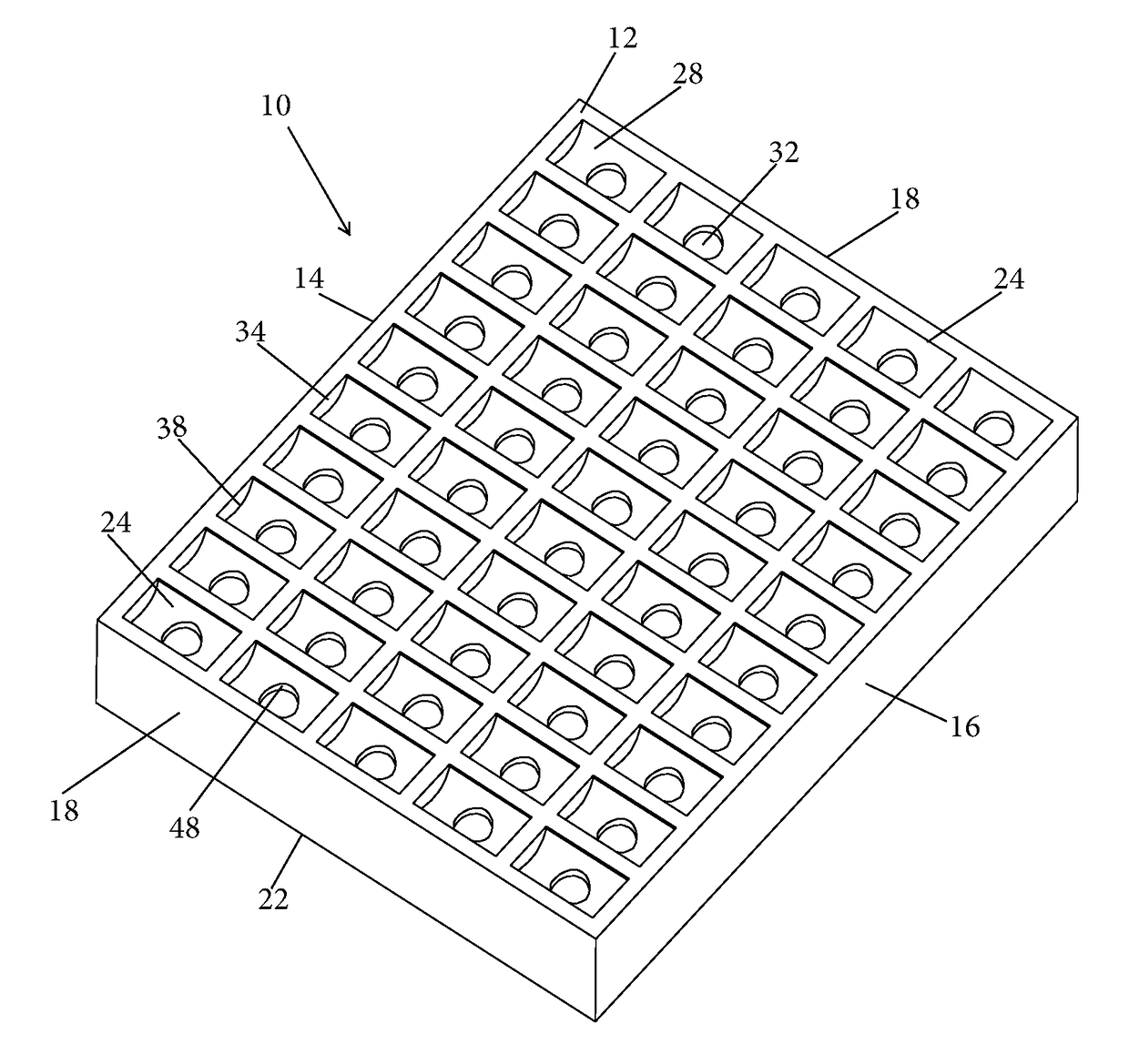

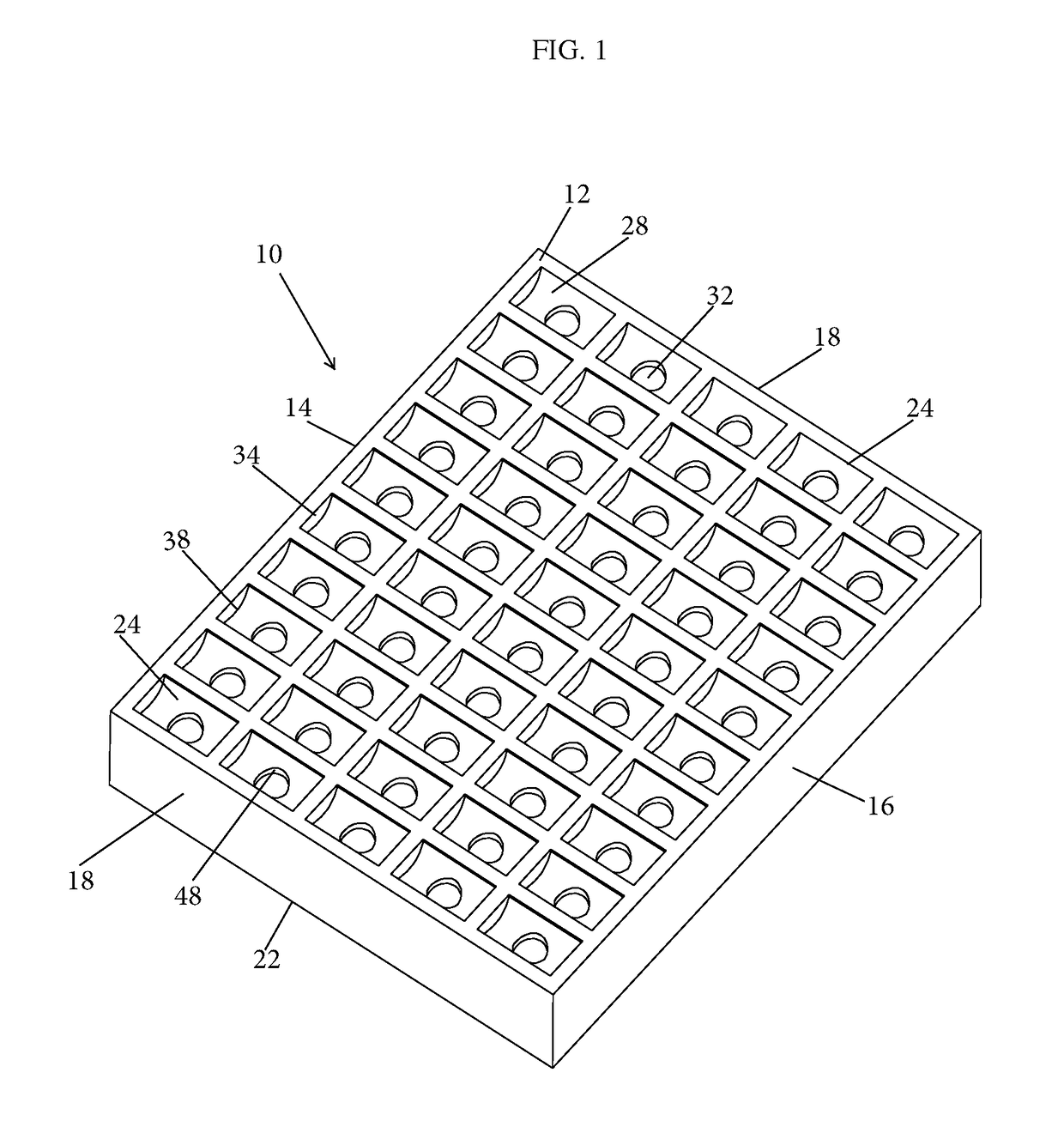

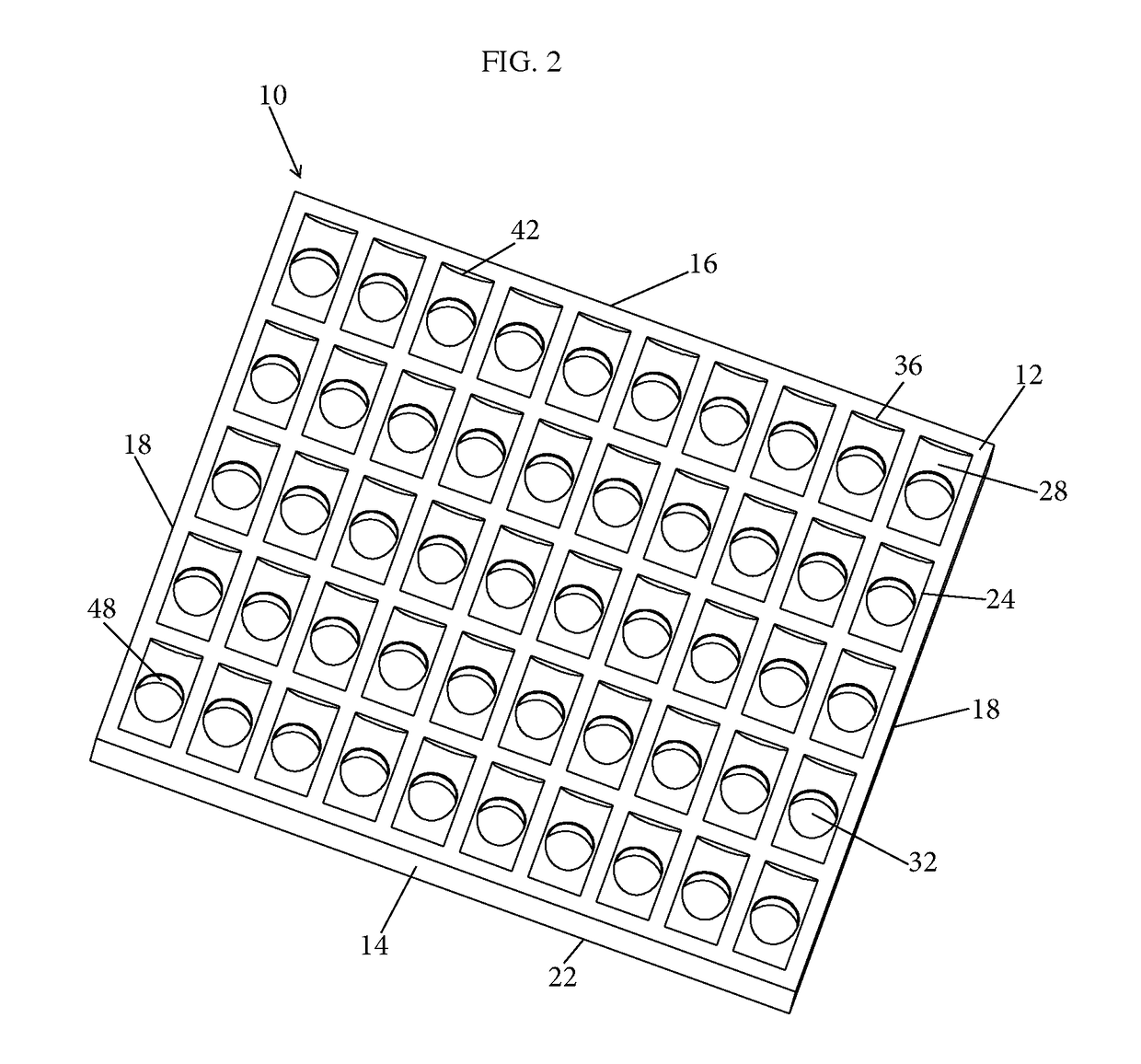

[0029]Referring now to the drawings, FIG. 1 shows the preferred embodiment of the case lube tray of the present invention generally indicated by the numeral 10. The case lube tray 10 has an exterior frame and is provided with a top frame 12, a front wall 14, a back wall 16, and side walls 18 being integral and forming a generally rectangular-shaped base 22. The top frame 12 is provided with openings defining a plurality of lubricating chambers 24.

[0030]The lubricating chambers 24 are mounting and lubricating means for shell cases 26 and are arranged in an array of horizontal rows and vertical columns. The shell cases 26 are mounted in a horizontal manner in each lubricating chamber 24 and prepared for lubrication. The user can inspect the lot and search for damaged shell cases 26, residual brass shavings from case-trimming and sort the shell cases 26 by size. The shape of each lubricating chamber 24 is such that appropriate spacing is kept between each shell case 26 and provides a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com