Apparatus and systems having an encased adsorbent contactor and swing adsorption processes related thereto

a technology of adsorption contactor and adsorption vessel, which is applied in the direction of silicon compounds, other chemical processes, separation processes, etc., can solve the problems of limiting the flow through capacity of such adsorption vessels, affecting the efficiency of adsorption, so as to prevent gaseous flow and prevent gaseous flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment a

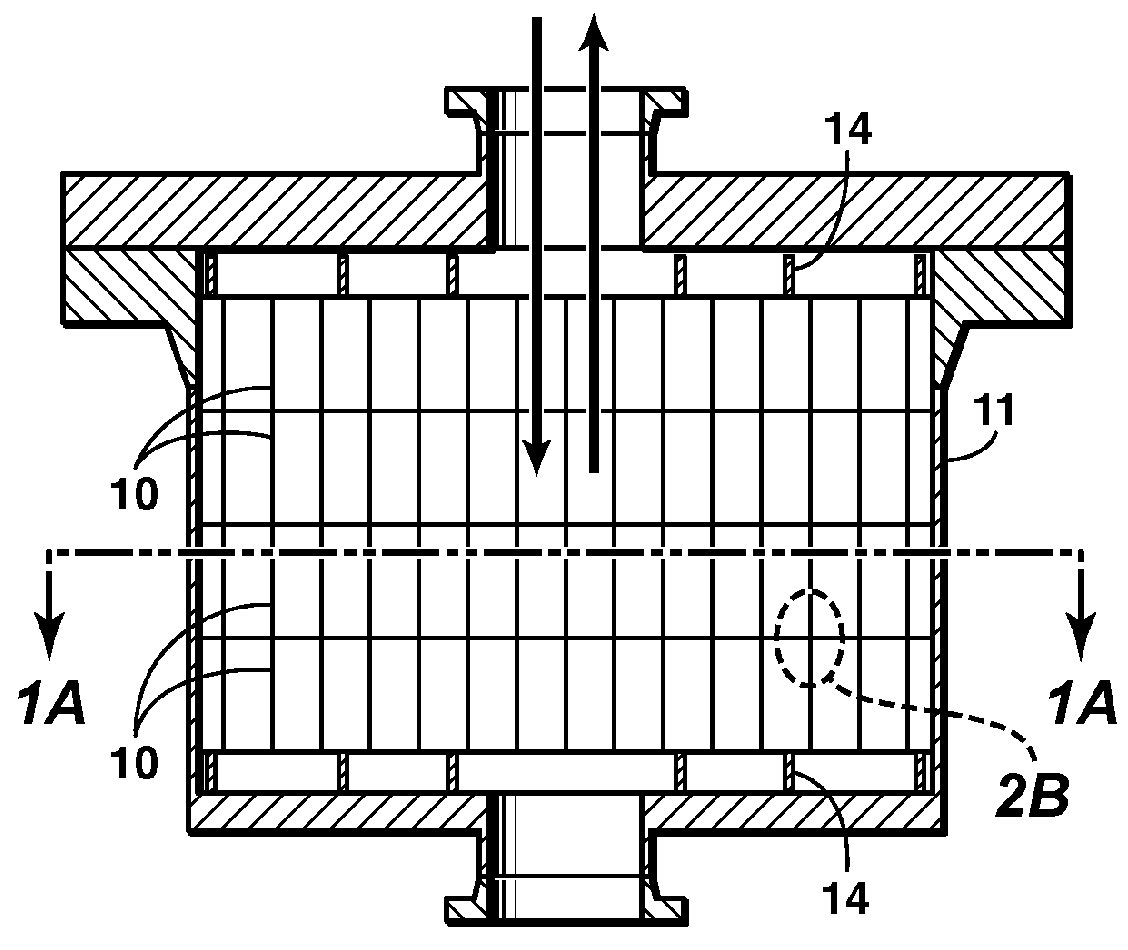

[0098]A swing adsorption contactor system comprising: a plurality of hollow rigid liners each having an inner surface and open axial ends, adjacent liners being fixedly connected to each other; a monolith adsorbent contactor being disposed within each liner, each monolith adsorbent contactor having an outer surface spaced from the inner surface of the liner; and a bonding agent disposed in the space between the outer surface of the monolith adsorbent contactor and the inner surface of the liner to form a seal to prevent gaseous flow in the space.

embodiment b

[0099]The swing adsorption contactor system of Embodiment A, wherein the monolith adsorbent contactor includes a stack of at least two monolith adsorbent contactors.

embodiment c

[0100]The swing adsorption contactor system of Embodiment B, wherein the stack of at least two monolith adsorbent contactors are held together by tape about adjacent axial ends of the two monolith adsorbent contactors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com