Image forming apparatus

a technology coupler, which is applied in the direction of electrographic process apparatus, instruments, optics, etc., can solve the problems of increasing manufacturing costs, increasing the number of parts, and difficulty in reducing the size and achieve the effect of image forming apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

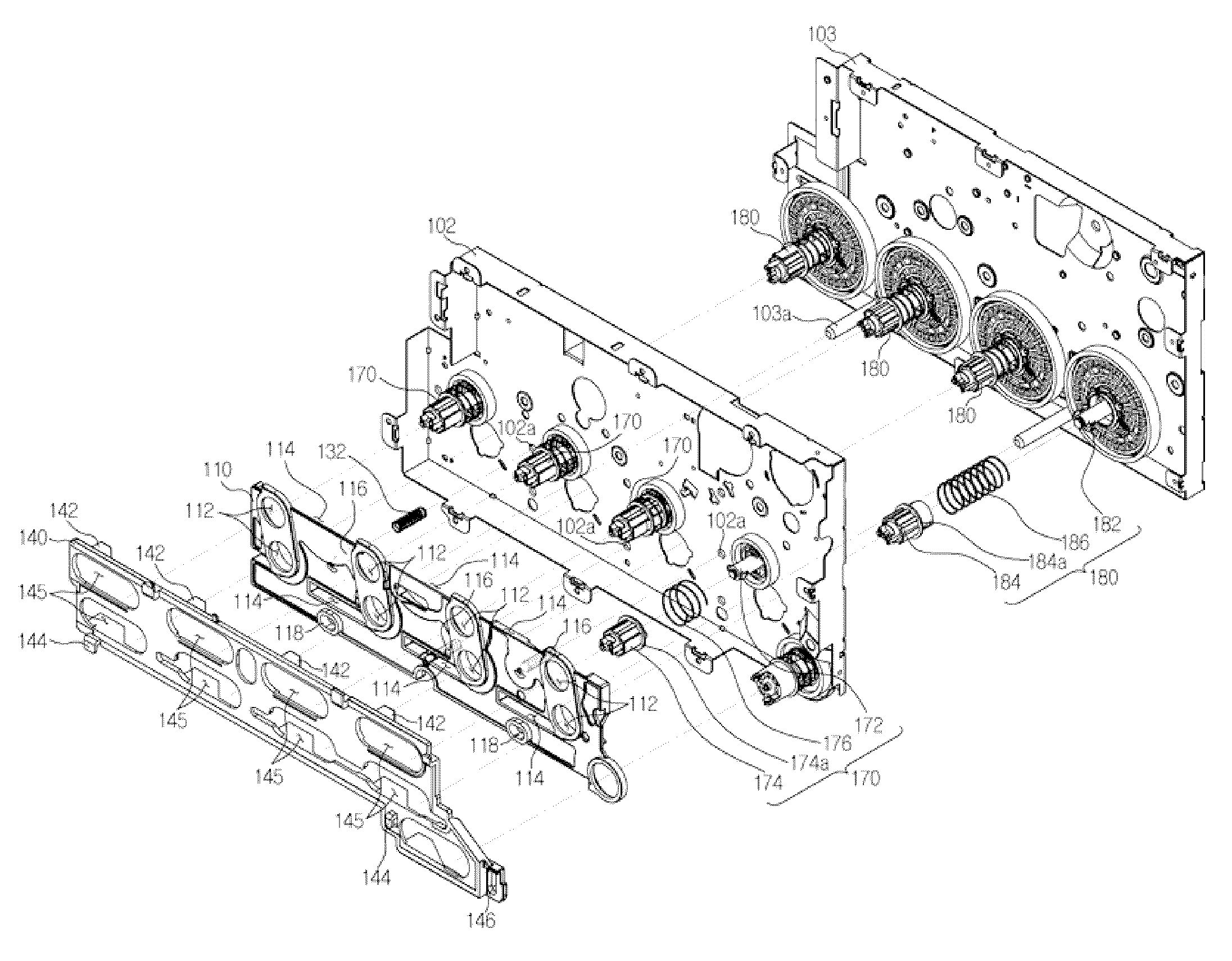

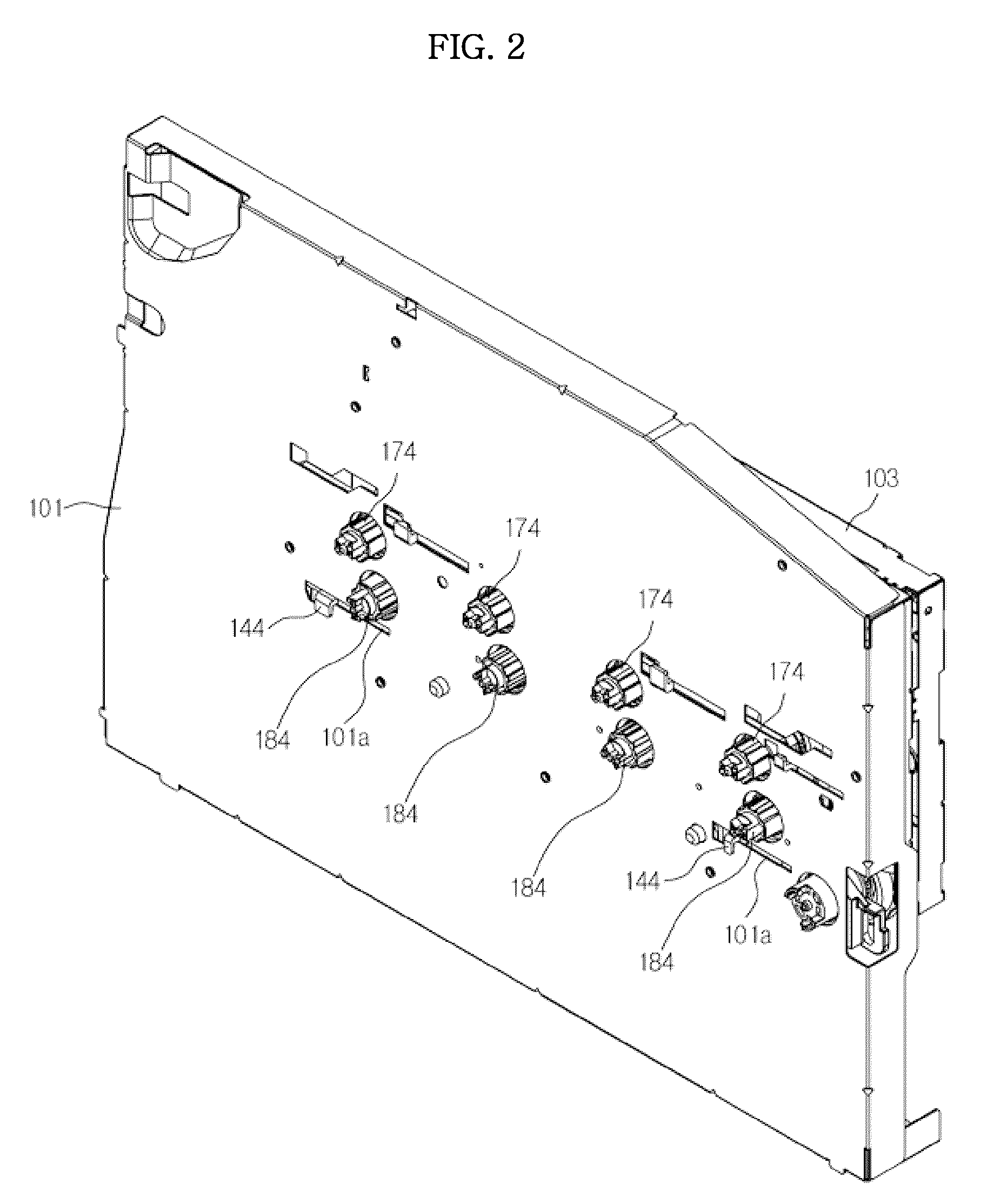

[0062]Reference will now be made in detail to the embodiments of the present general inventive concept, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The embodiments are described below in order to explain the present general inventive concept while referring to the figures.

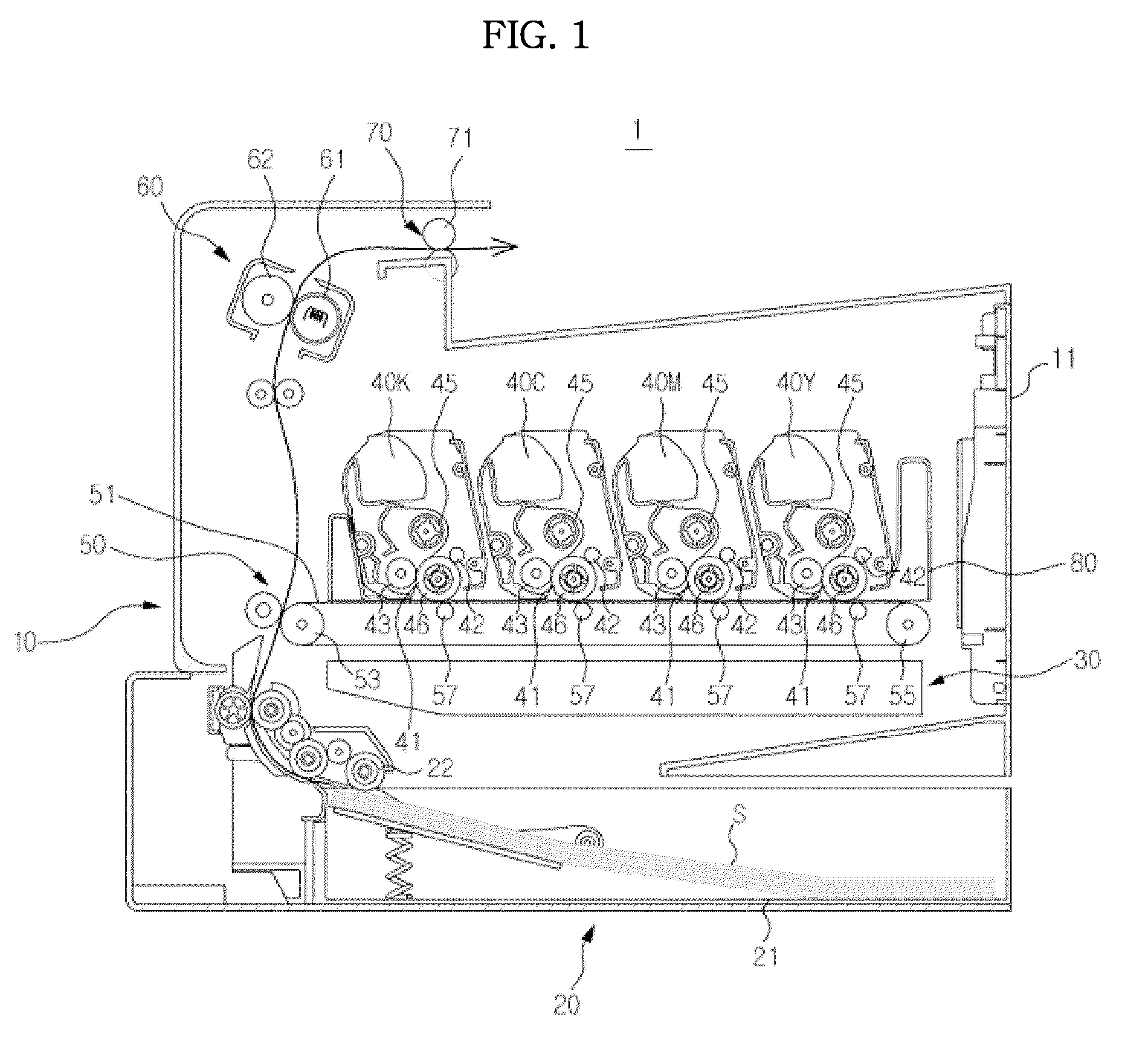

[0063]FIG. 1 is a view schematically showing the construction of an image forming apparatus according to an exemplary embodiment of the present inventive concept.

[0064]As shown in FIG. 1, an image forming apparatus 1 includes a main body 10, a print media supply unit 20, an optical scanning unit 30, a developing cartridge 40, a transfer unit 50, a fusing unit 60, and a print media discharge unit 70.

[0065]The main body 10 forms the external appearance of the image forming apparatus 1 and supports various components installed therein. A cover 11 is rotatably installed at one side of the main body 10. The cover 11 opens and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com