Cooking vessel with nonstick coating

a non-stick coating, cooking vessel technology, applied in the direction of roasters/grills, cooking vessel materials, frying pans, etc., can solve the problems of difficult cleaning of saucepans or pans, adversely affecting the appearance of food, hazardous substances that are bad for the health of consumers, etc., to achieve the effect of safe us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

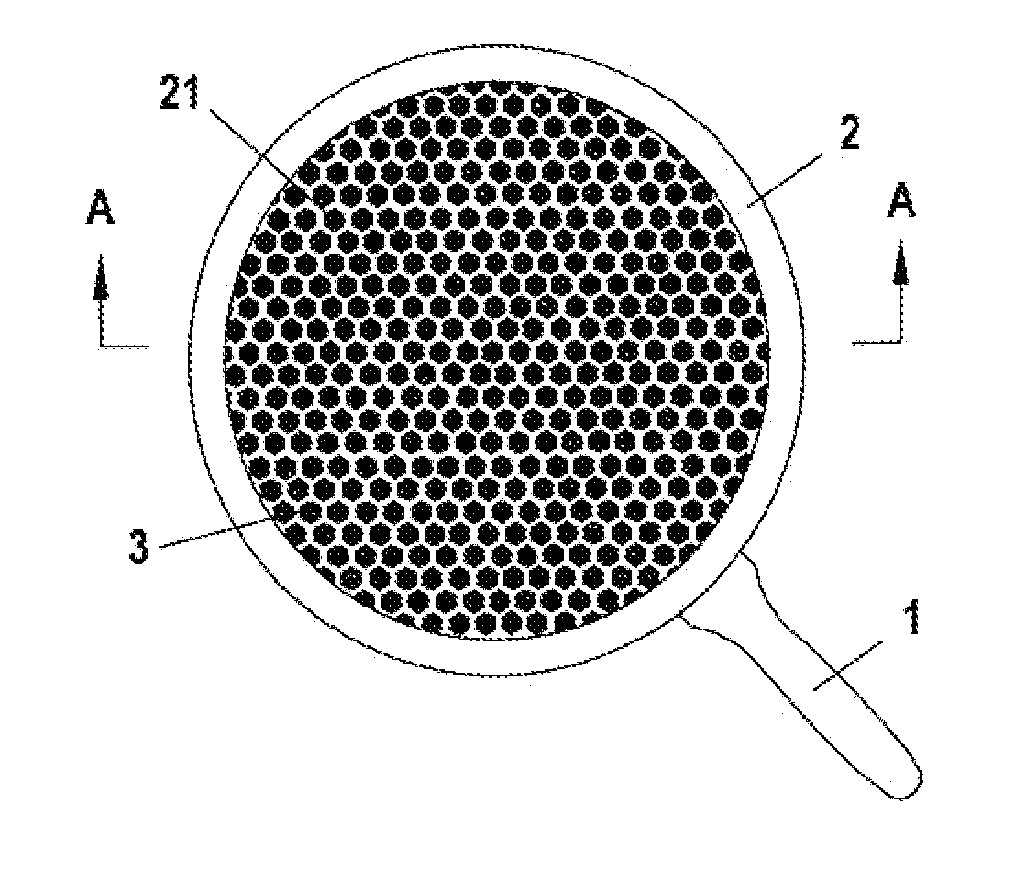

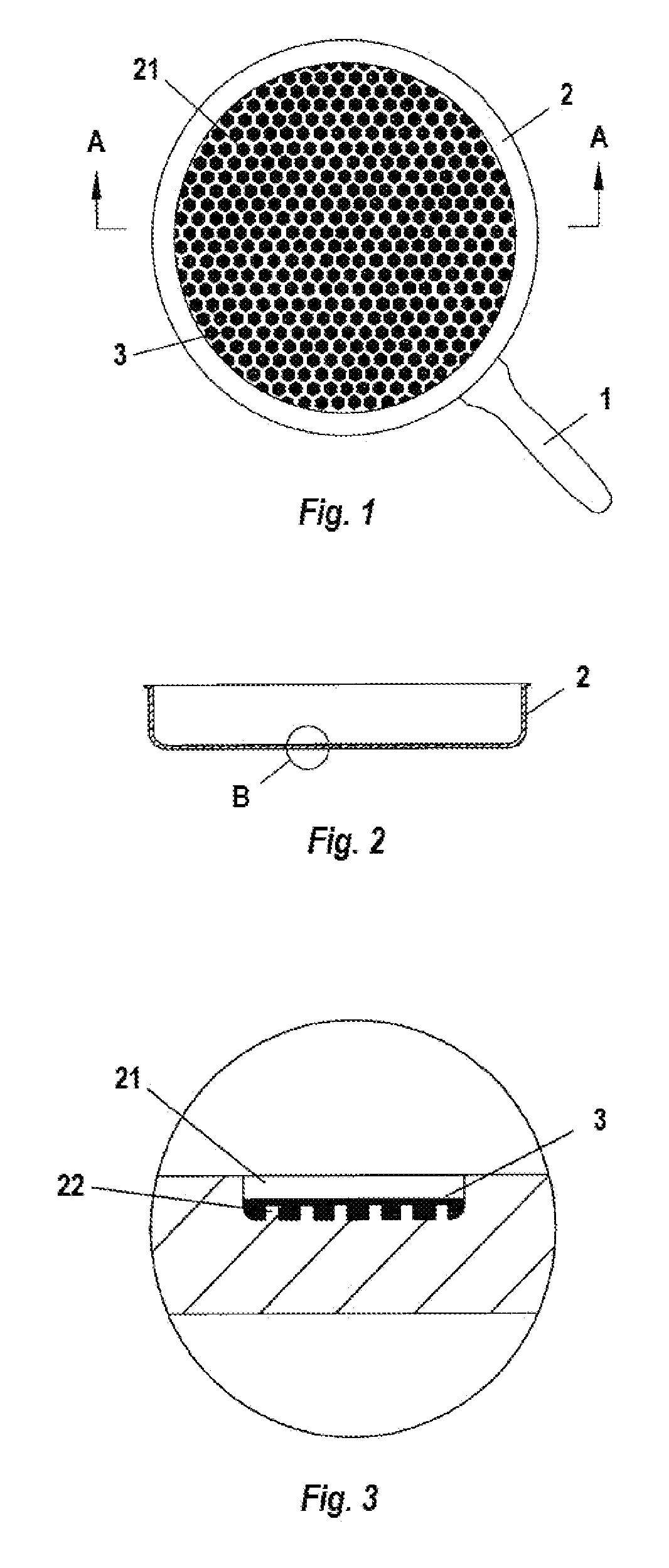

[0012]The invention is explained in more detail below with reference to a pan having a nonstick coating. FIGS. 1, 2, and 3 show that the pan has a handle 1 and a body 2. The upwardly directed inner face of the body 2 is provided with a multiplicity of connected or disconnected oil cavities 21 that are uniformly distributed over this inner face. As can be seen in FIG. 1, the above-described oil cavities 21 can be of a hexagonal, round, square, polygonal or any other shape. The floors of the oil cavities 21 are each provided with a respective uniform array of small studs that can be connected or disconnected with one another. The studs 22 can be cylindrical or in the form of columns of square section. The oil cavities 21 and the small studs can also be formed and arranged differently if required.

[0013]The height of the above-mentioned small studs 22 is less than the depth of the oil cavities 21. The depth of the above-described oil cavities 21 lies between approximately 0.1 mm and 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com