Device for measuring seal gaps of vehicles

a technology for sealing gaps and measuring devices, which is applied in the direction of measurement devices, measurement gauges, instruments, etc., can solve the problems of difficult to measure precise dimensions, transmission of wind noise, and inability to move parts and fixed mounting parts of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]It should, of course, be understood that the description and drawings herein are merely illustrative and that various modifications and changes can be made in the structures disclosed without departing from the present disclosure. It will also be appreciated that the various identified components of the exemplary device for measuring vehicle seal gaps disclosed herein are merely terms of art that may vary from one manufacturer to another and should not be deemed to limit the present disclosure.

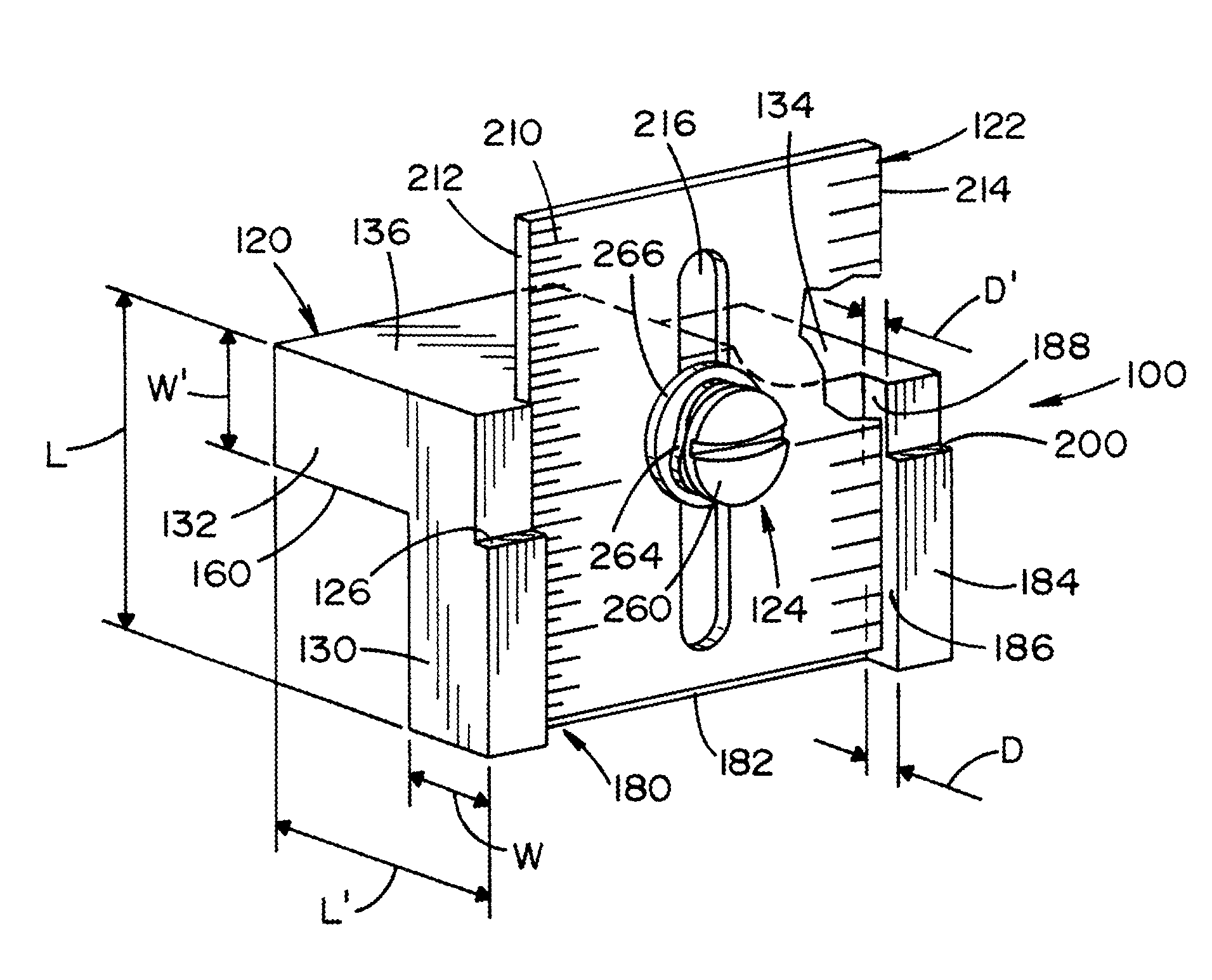

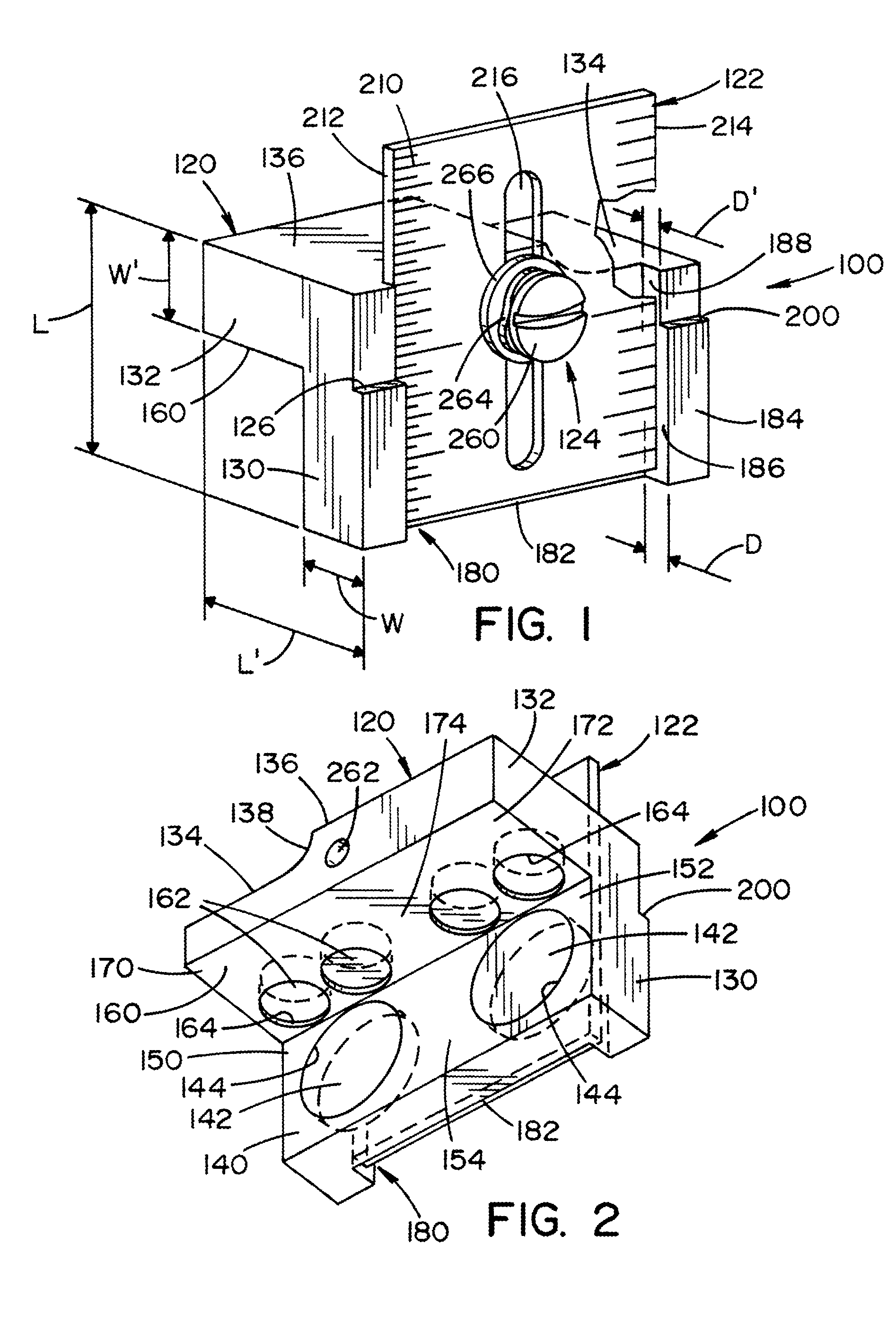

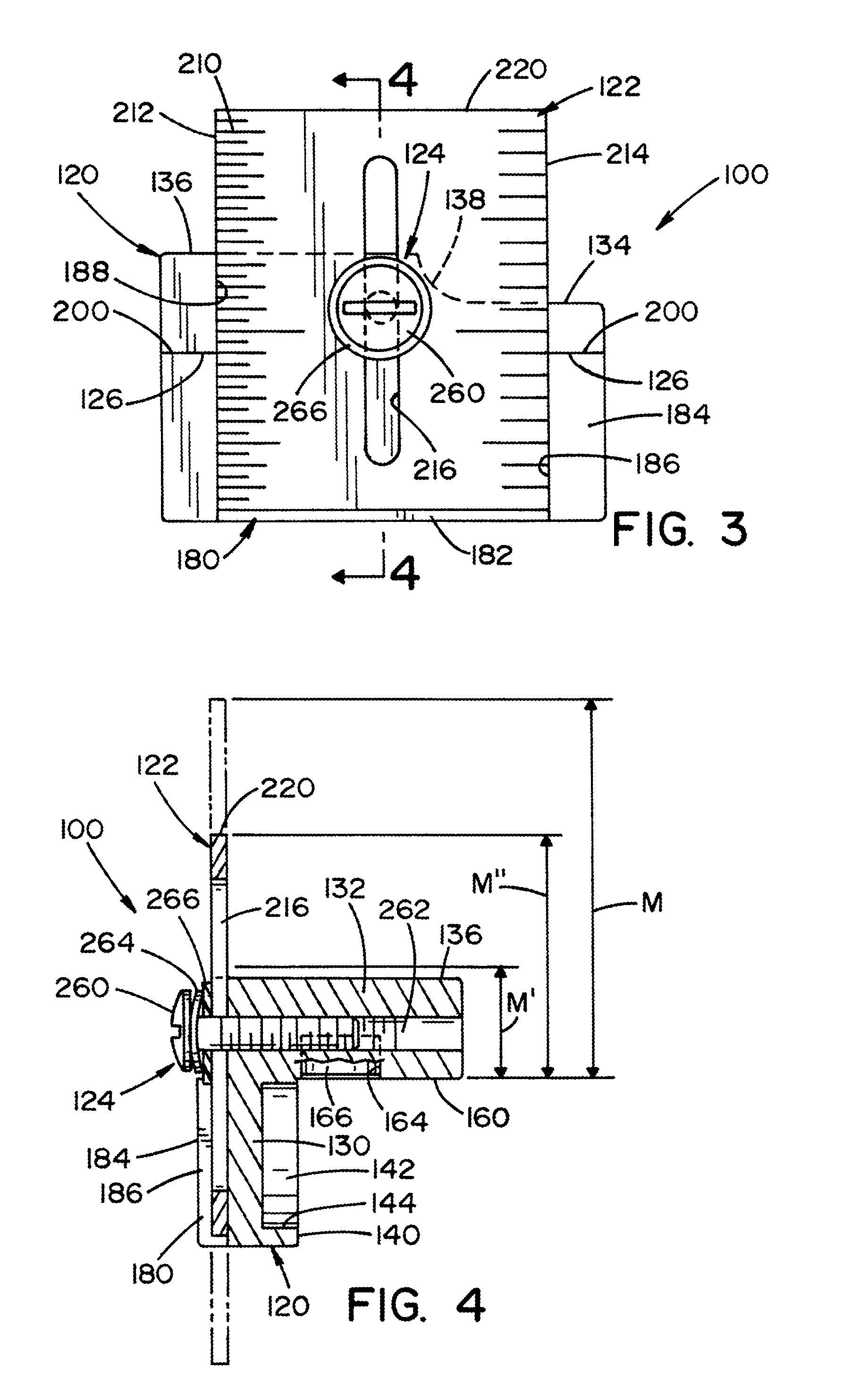

[0026]Referring now to the drawings, wherein like numerals refer to like parts throughout the several views, FIGS. 1-3 illustrate an exemplary device 100 for measuring a seal gap 102 created between a moving part 104 and a mounting part 106 of a vehicle body 108 (FIGS. 5 and 6) according to one aspect of the present disclosure. As shown, the moving part 104 can be a tailgate structure 110 (FIG. 6), a door structure 112 (FIG. 8) and the like. As shown in FIGS. 5 and 6, the mounting part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com