Collapsible projection screen systems

a projection screen and collapsible technology, applied in the field of collapsible projection screen systems, can solve the problems of difficult to provide a flat screen surface, and achieve the effects of reducing the difficulty of hoisting facilitating screen support, and lowering the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

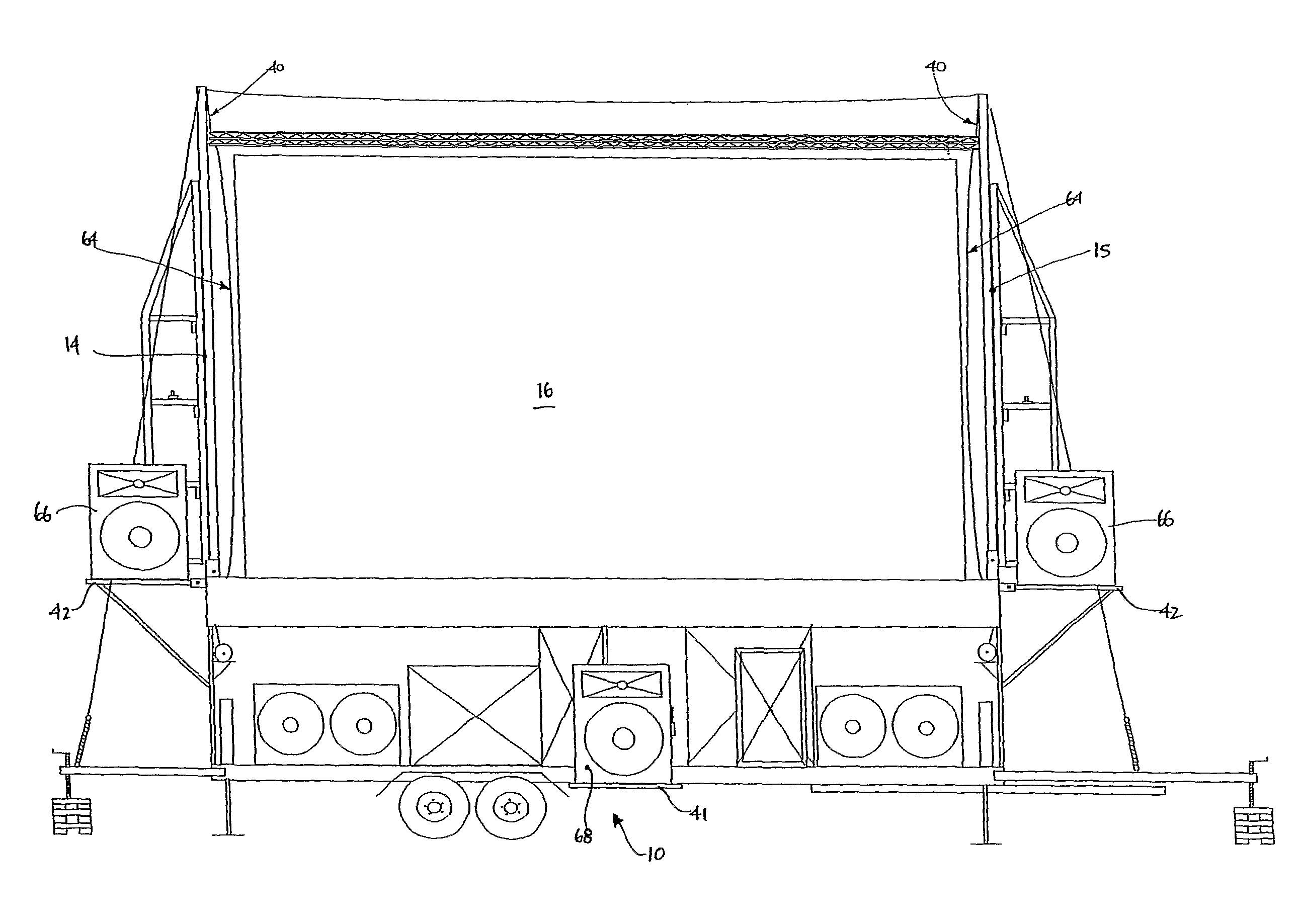

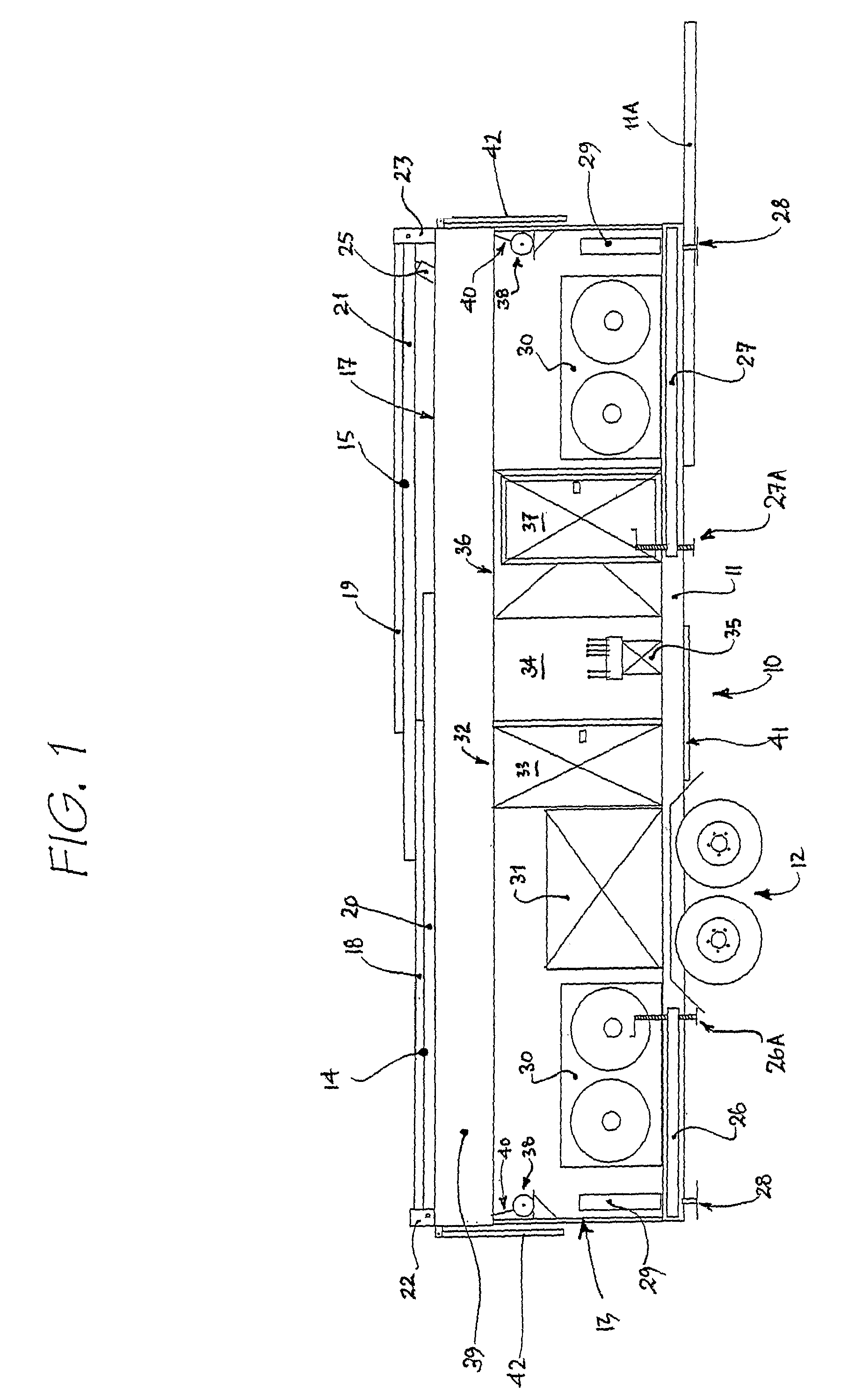

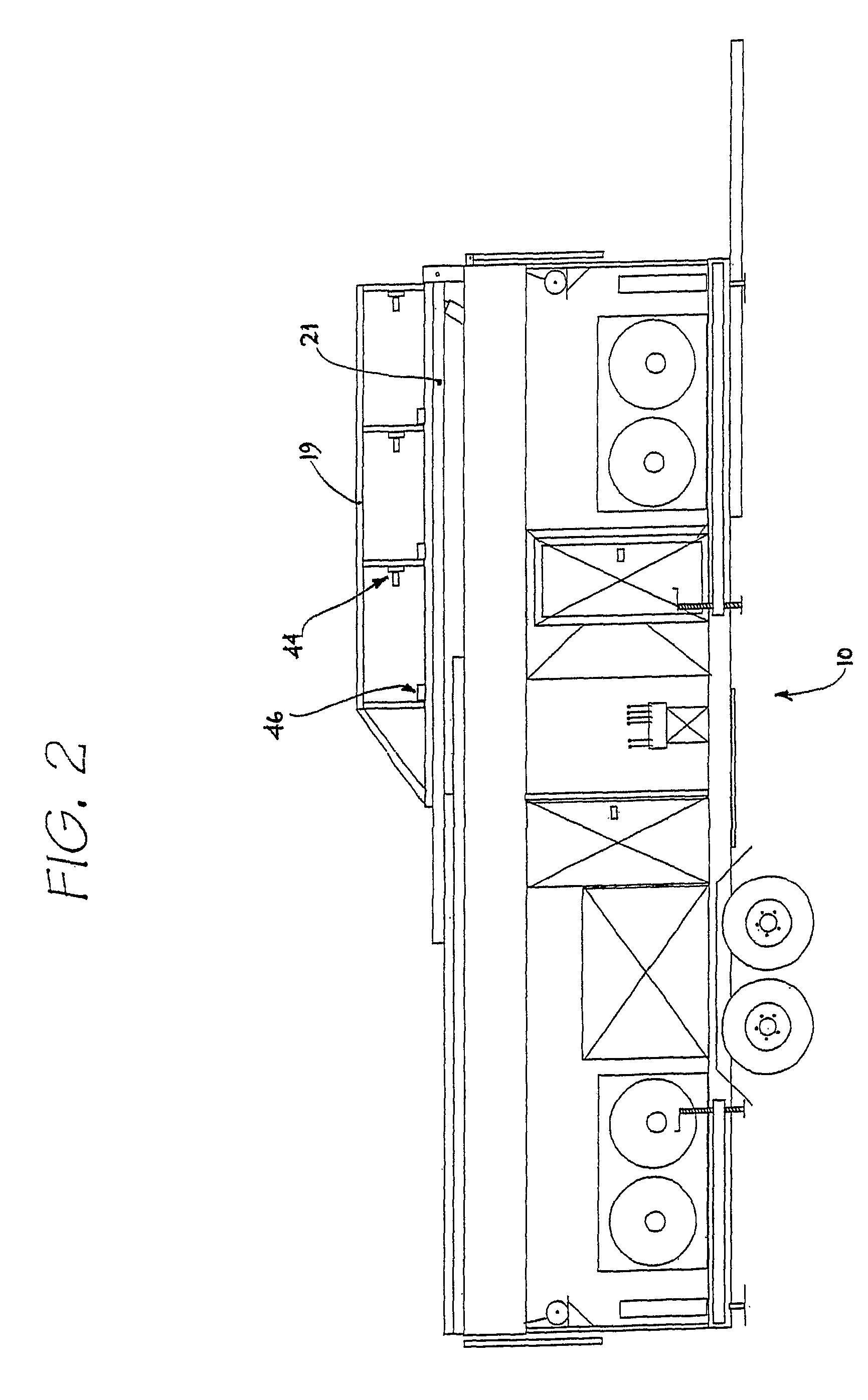

[0068]FIGS. 1 to 7 show the sequential erection of a collapsible projection screen system in accordance with the invention. FIG. 1 shows the system in its collapsed (transportation or storage) configuration and FIG. 7 shows the system in its fully erect (in use) configuration. Additional features of the assembly are shown in FIGS. 8 to 10.

[0069]As shown in FIGS. 1 to 7, the collapsible projection screen system typically comprises and is incorporated into a trailer 10. The system further comprises a chassis 11 to which is mounted a wheel assembly 12 and a trailer superstructure 13. A trailer hitch 11A extends from the chassis. Left and right screen support assembles 14, 15 are hingedly mounted to the superstructure 13 of the trailer 10 and are pivotable between a collapsed position as shown in FIG. 1 and a screen support position as shown in FIGS. 4 to 7. The system also includes a flexible projection screen 16, as shown in FIGS. 5 to 7, which is moveable between a collapsed position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com