Stator

a stator and cylinder technology, applied in the field of stators, can solve the problems of difficult mechanization work, uneven torque, uneven force generation density in a running direction, etc., and achieve the effect of higher coil end, higher-performance stators, and higher occupancy ratios in the slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086]The preferred embodiments of the present invention are described below with reference to the drawings.

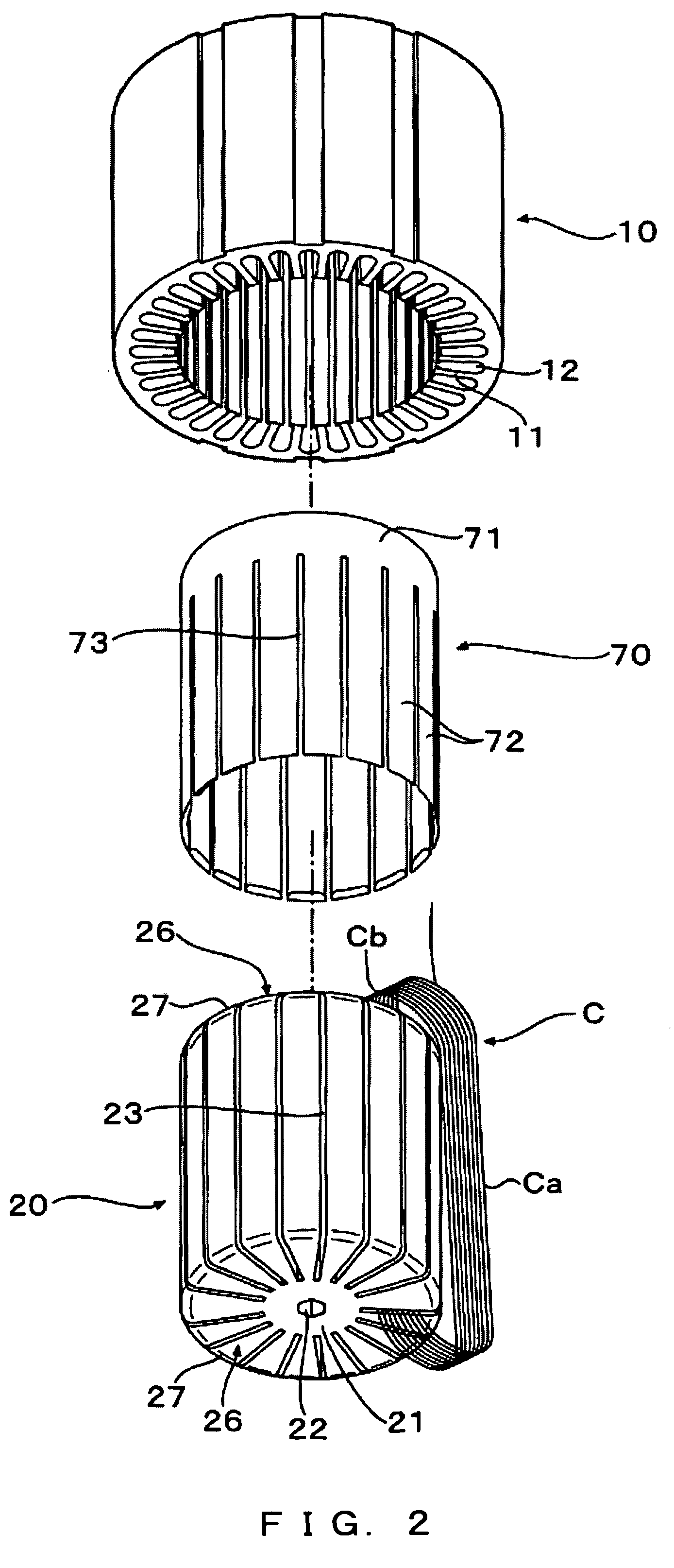

[0087]FIGS. 1 and 2 show one example of the device for manufacturing the stator of the present invention.

[0088]In FIGS. 1 and 2, a reference numeral 10 is a stator core and the stator core 10 comprises inner teeth 11 in its inner perimeter. Then, a slot 12 is formed between the inner teeth 11.

[0089]This manufacturing device comprises a jig 20 almost cylindrical as a whole, which is inserted in the inner perimeter of the stator core 10. The jig 20 comprises a shaft unit 21 at the center, a hole 22 provided at the center of the top end surface of this shaft unit 21 and a plurality of holding grooves 23 radiantly formed from the outer perimeter of the shaft unit 21 toward the cylindrical outer perimeter of the shaft unit 21.

[0090]The holding grooves 23 are formed with a pitch integer times as that of the slot 12 of the stator core 10. Although in the case of this example, the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com